You know, this pre-painted metal, it’s a smart thing, really. They take these big rolls of metal, like steel or aluminum, and slap some paint on it right in the factory, all before anyone starts bending or cutting it. Now, back in the old days, metal came to the factory plain and bare. Workers had to put in all that elbow grease to cut it, shape it, and only then put on some paint. Oh, what a hassle that was! But nowadays, with this coil coating – that’s what they call the factory painting – it’s all set up before it even hits the work site.

And why do folks do this, you ask? Well, think about it. You want your metal to last, right? Turns out, when they do this pre-painting, the metal gets this extra strong layer that fights off rust and weather. So, even if it’s sitting out in the rain or snow, that paint helps keep it nice and fresh-looking. You’ll see it on roof panels, home siding, and all sorts of stuff. Some folks even say these panels can last over 50 years. Now, that’s something, isn’t it? Compare that to plain metal, which doesn’t last half as long.

So, what metals can be pre-painted? Turns out, they do this on a few types, but mostly steel and aluminum. Steel, well, that’s tough and can take a beating, but it rusts without a bit of help. Aluminum doesn’t rust so bad, but it still needs some protection. By putting a coat of paint on right at the start, both these metals get a good layer of protection right off the bat. Saves everyone a lot of trouble down the line, trust me on that.

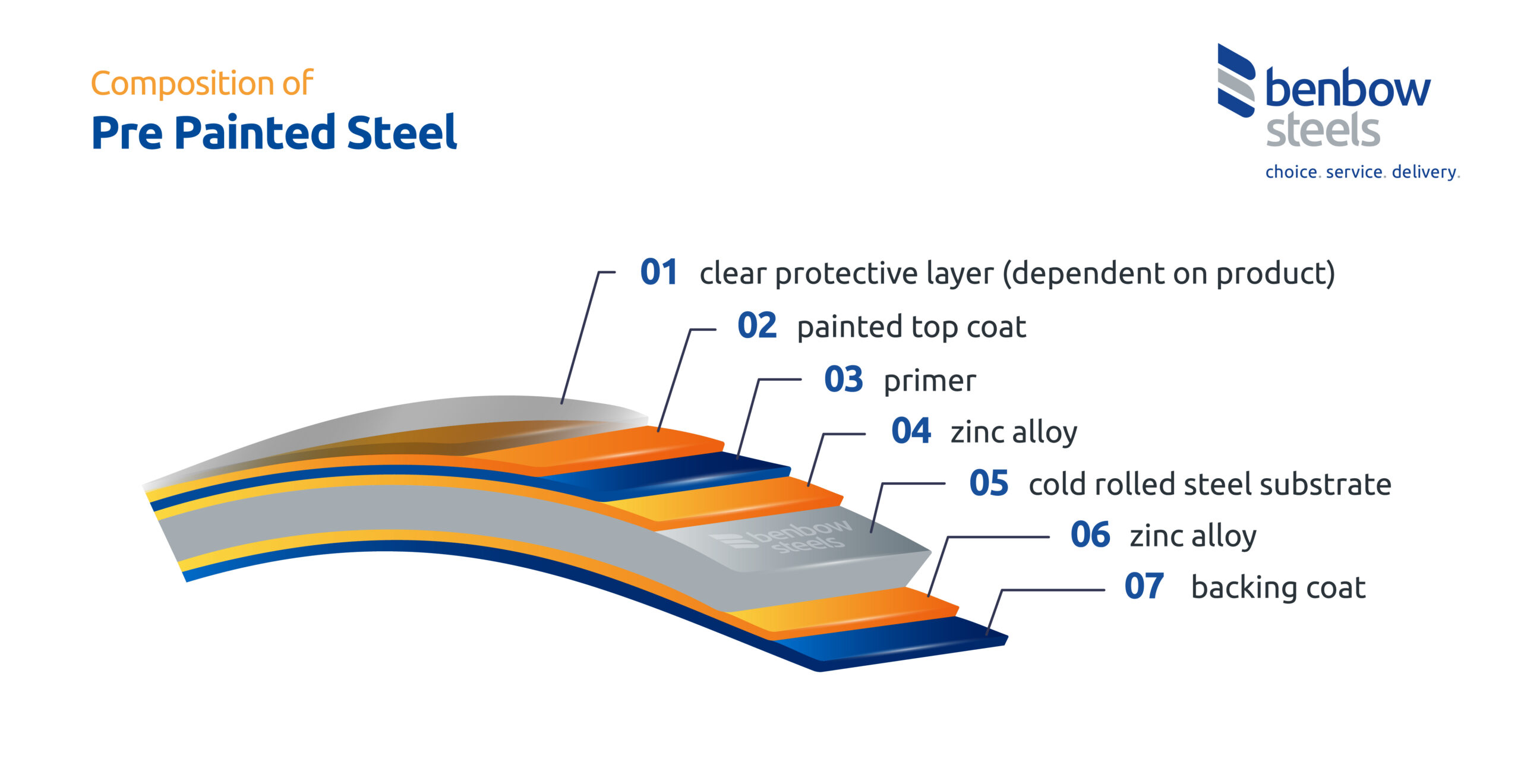

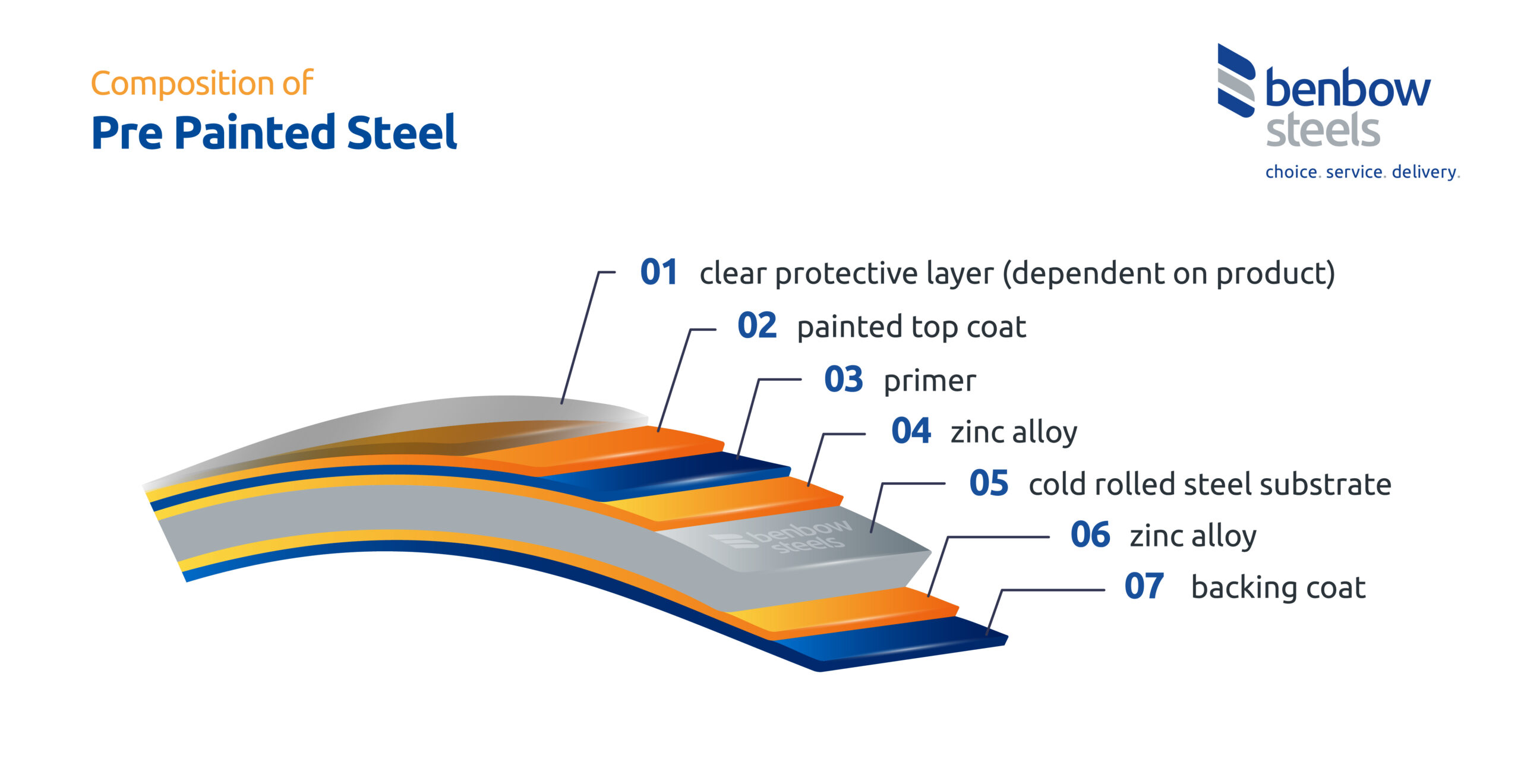

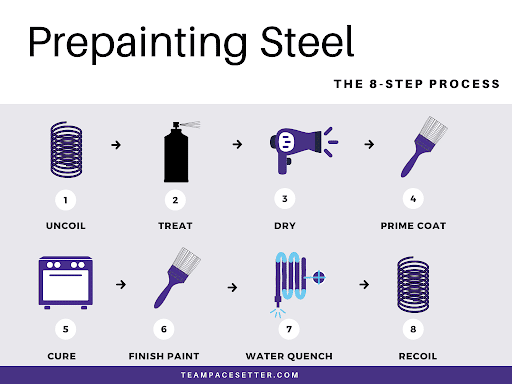

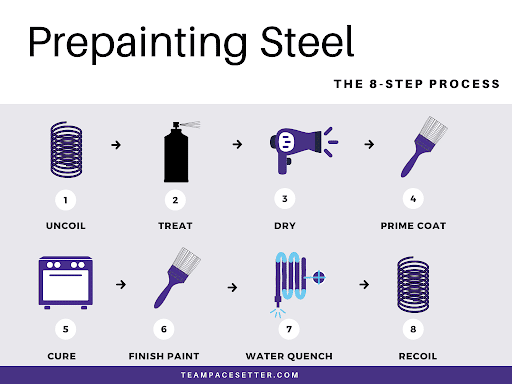

Now, I’ll tell you something about how they do it. They call it the coil coating process. Picture this: the metal goes through this big ol’ machine, like rolling dough through a pasta maker, but faster, and instead of noodles, you get painted metal sheets. They put the metal in, and it runs through layers of paint, sometimes two or three, depending on what they need. Then they bake that paint right on there with some high heat. When it comes out, that paint is like a part of the metal itself – no peeling, no bubbling, nothing.

What’s it used for, you’re asking? Well, everywhere, really.

- Think of buildings – roofs, sidings, and trims.

- Some folks put it on doors and even window frames.

- Even cars and trucks sometimes use pre-painted panels!

It’s because the paint sticks well, and when they bend or cut the metal, it doesn’t flake off. That’s real important for things that need to be shaped, like roof panels. Can’t have a roof with peeling paint, right?

And here’s another thing – because this paint job is so solid, it’s better for the environment. They don’t have to use all those sprays and solvents on-site, which keeps things a bit cleaner. Plus, the whole process is quick and neat. Imagine all that mess if everyone painted metal on-site! This way, the factory does it, and the rest of us get to enjoy clean air.

So, is pre-painted metal worth it? Oh, you bet it is! If you’re thinking about putting up a new roof or even some siding on the barn, this pre-painted stuff is top-notch. It might cost a tad more upfront, but let me tell you, that durability pays off. No need to climb up there with a paintbrush every few years. And for folks who want color choices, this pre-painted metal comes in a whole rainbow of colors. It’s nice to have options without worrying about paint chipping off the next time it hails.

All in all, this pre-painted metal is a real winner. Keeps things looking good, lasts a long time, and saves everyone a bit of work. Not a bad deal, if you ask me!

Tags:[pre-painted metal, coil coating, prepainted steel, durable roofing, building materials]