Alright, let’s talk about this metal stuff, you know, the sheet metal thickness. I ain’t no engineer, but I know a thing or two ’bout pickin’ the right metal for the job. You gotta get it right, or things just fall apart, ya hear?

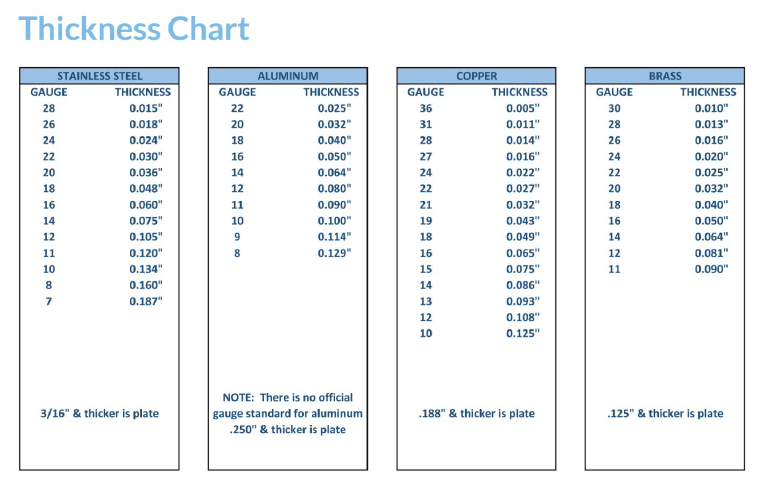

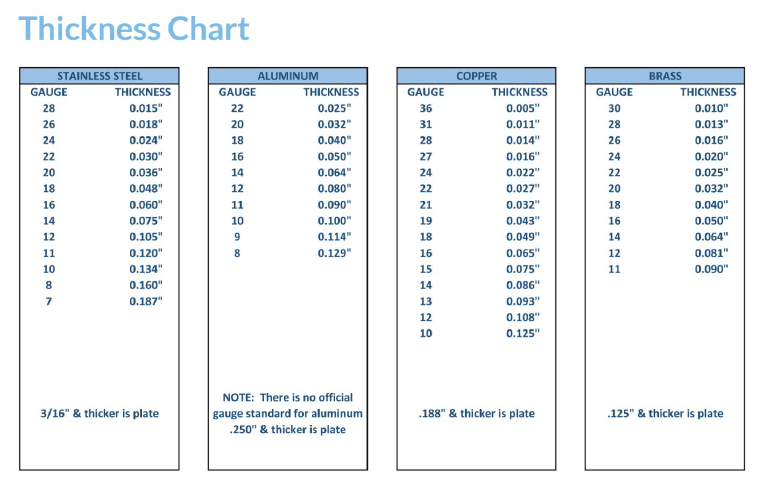

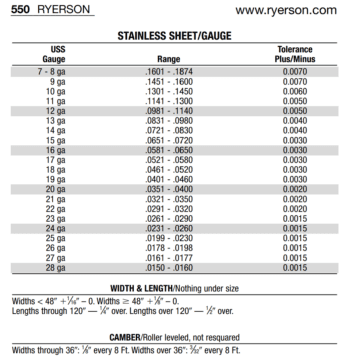

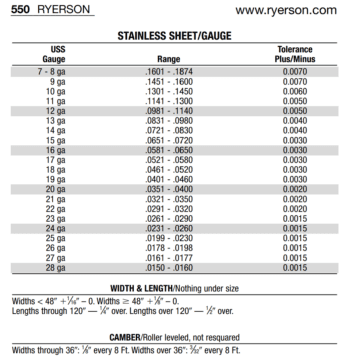

First off, they got these things called “gauges.” Now, don’t ask me why, but the smaller the gauge number, the thicker the metal. It’s like backwards day, I tell ya. So, a 7 gauge is gonna be a whole lot thicker than a 26 gauge. Makes no sense, but that’s how them city folks do it.

- Thick stuff (like 7 gauge and lower): That’s for when you need somethin’ strong, somethin’ that can hold up a lot of weight. Think heavy machinery, or maybe somethin’ that needs to take a real beatin’.

- Thin stuff (like 26 gauge and higher): That’s for when you don’t need so much strength, and you wanna keep things light. Maybe for makin’ cans, or little covers, or somethin’ like that.

Now, if you go buyin’ this metal, you gotta pay attention to what they call it. If it’s thinner than a quarter of an inch, they call it “sheet.” If it’s thicker than that, they call it “plate.” Simple as that. And they measure the plate in inches, not gauges. Again, makes no sense, but that’s the way it is.

So, how do you pick the right thickness? Well, it all depends on what you’re doin’ with it. You gotta think about the weight it needs to hold. If it’s gonna be holdin’ up somethin’ heavy, you need somethin’ thick. If it’s just gonna be sittin’ there, not doin’ much, you can go with somethin’ thinner.

I remember this one time, my nephew, he tried to build a shed usin’ some real flimsy metal. Said he was gonna save some money. Well, let me tell you, that shed didn’t last a week. First good wind came along, and it just folded up like a cheap suit. He shoulda listened to his old aunt and used somethin’ thicker. That’s why choosing the right sheet metal thickness is so important.

And another thing, don’t go thinkin’ you can just bend the metal any which way to make it stronger. Sure, bendin’ it can help a little, but it ain’t gonna make up for usin’ too thin a metal in the first place. You gotta start with somethin’ strong enough for the job.

Nowadays, they got all sorts of different thicknesses you can buy. I heard tell of somethin’ called “20 gauge equivalent,” and even that can be different thicknesses dependin’ on who you buy it from. So, you gotta pay attention, ya hear? Don’t just grab any old piece of metal and think it’ll do. You need to measure, understand if you need sheet or plate.

And don’t forget, the thicker the metal, the heavier it’s gonna be, and the more it’s gonna cost. So, you gotta find that sweet spot, you know? Somethin’ strong enough to do the job, but not so heavy that you can’t lift it, and not so expensive that it breaks the bank. It’s all a balancing act, I tell ya.

So, there you have it. A little bit about sheet metal thickness, from someone who’s seen a thing or two. Just remember, think about the weight, pick the right gauge, and don’t be afraid to ask for help if you need it. And for goodness sake, don’t skimp on the metal like my nephew, you’ll just end up doing it all over again.

Tags: [Sheet Metal Thickness, Sheet Metal Gauge, Metal Plate, Metal Sheet, Gauge Thickness, Metal Thickness Guide]