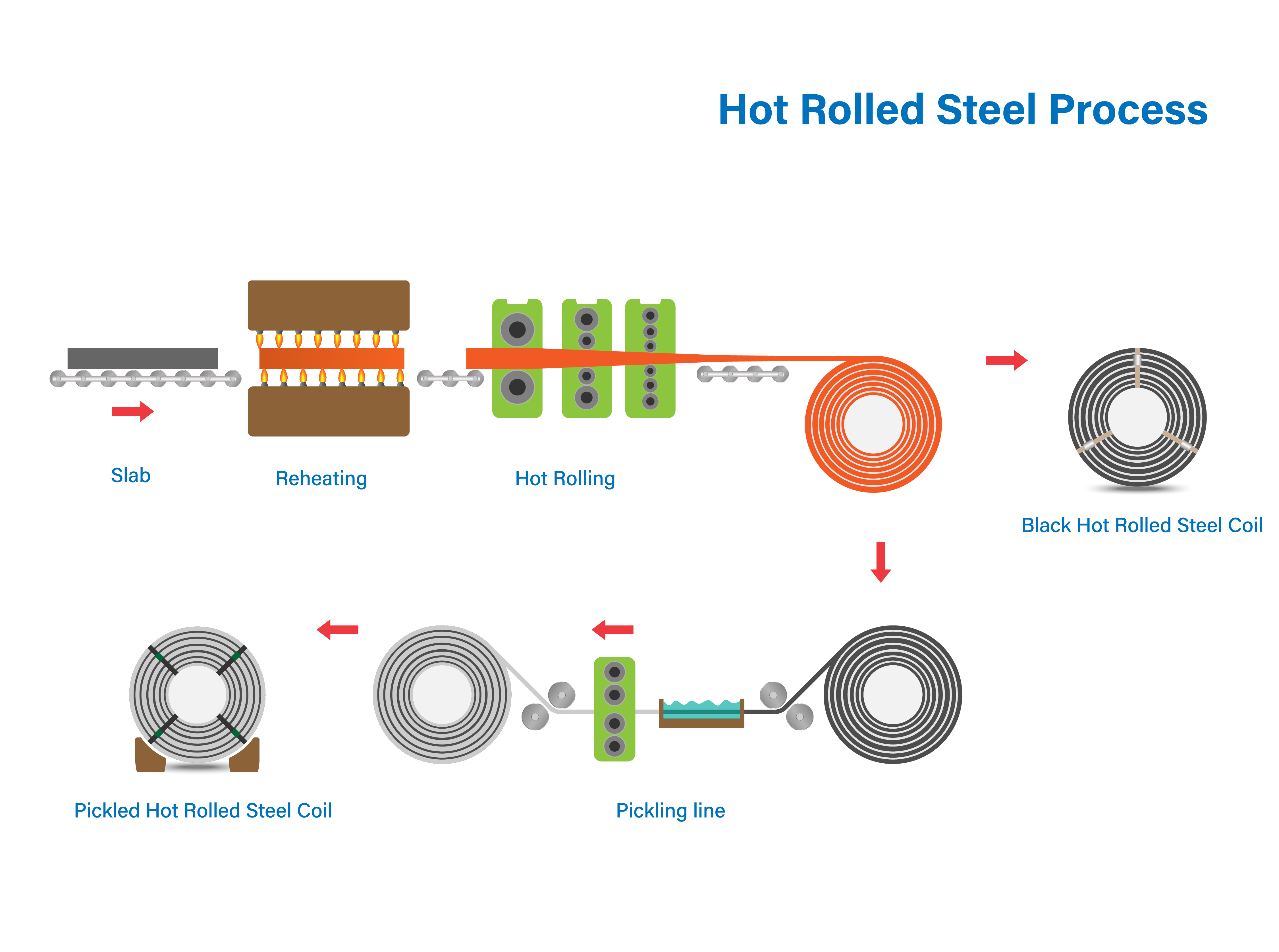

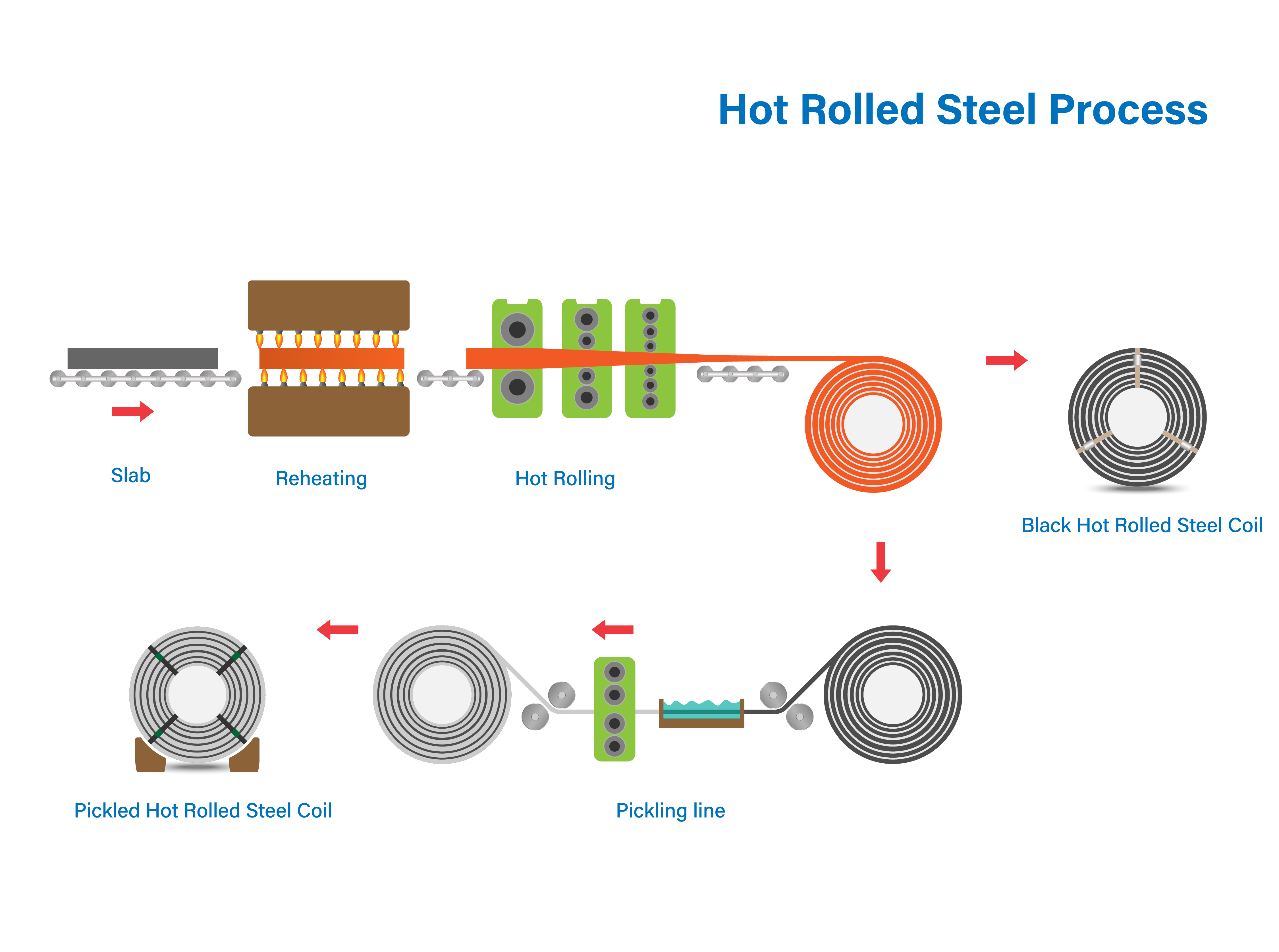

Well, let me tell ya somethin’ about how they make that steel stuff, the hot rollin’ kind, ya know? It ain’t no easy thing, that’s for sure. First off, they gotta heat that metal up real good, hotter than your oven ever gets, I tell ya. Like, more than 1,700 degrees hot! Why? Cause that makes it soft like butter, easy to squish around.

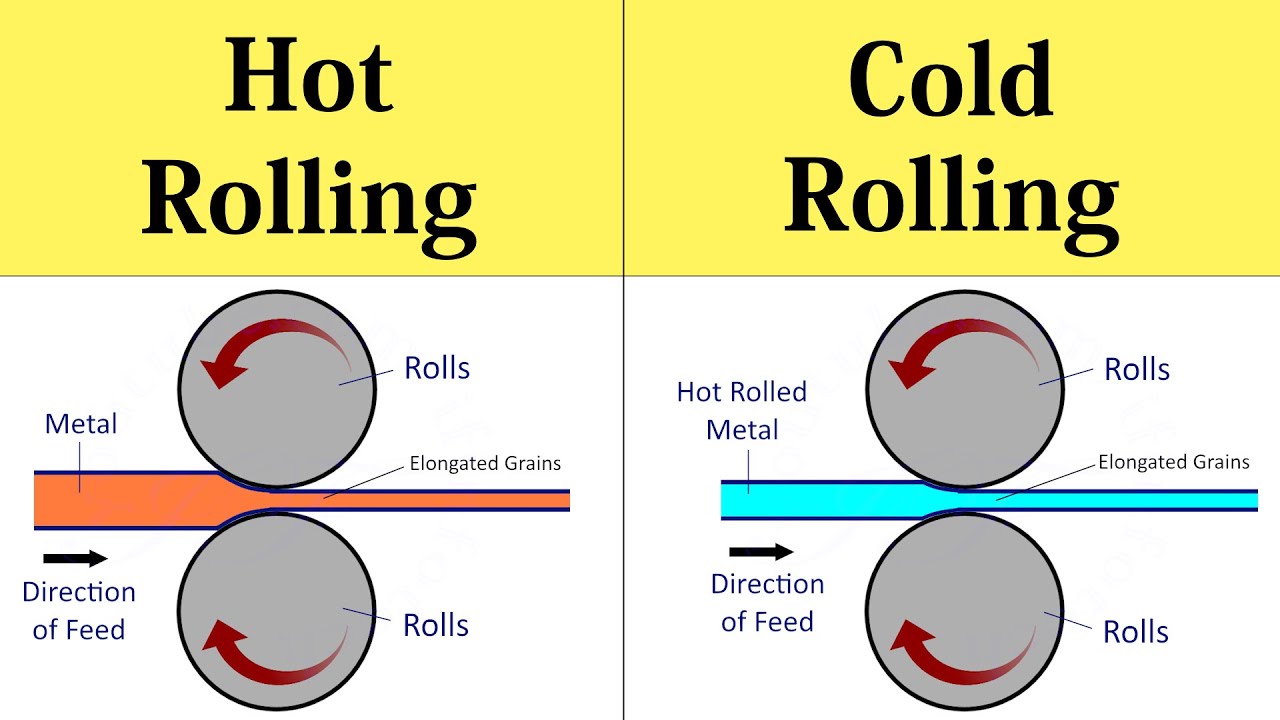

They call that “re-crystallization temperature,” fancy words for makin’ it bendy. They heat up these big ol’ chunks of steel, they call ’em slabs, looks like big ol’ bricks to me. Then, they shove ’em through these giant rollers, big metal thingamajigs that spin and squeeze. Think of it like rollin’ out dough for biscuits, but way, way bigger and hotter.

- First, they got this “roughing mill”, that’s the big fella that starts squishin’ the steel down. Makes it thinner and kinda takes the shape.

- Then, there’s this other thing, the “intermediate mill,” that keeps squishin’ and shapin’ it more.

They keep doin’ this, rollin’ and squishin’, till they get it just the right size and shape. Thick or thin, wide or narrow, however the customer wants it. It’s all about gettin’ that steel into the right shape, see? It’s kinda like makin’ noodles, I guess. You gotta roll and stretch ’em out to get ’em just right.

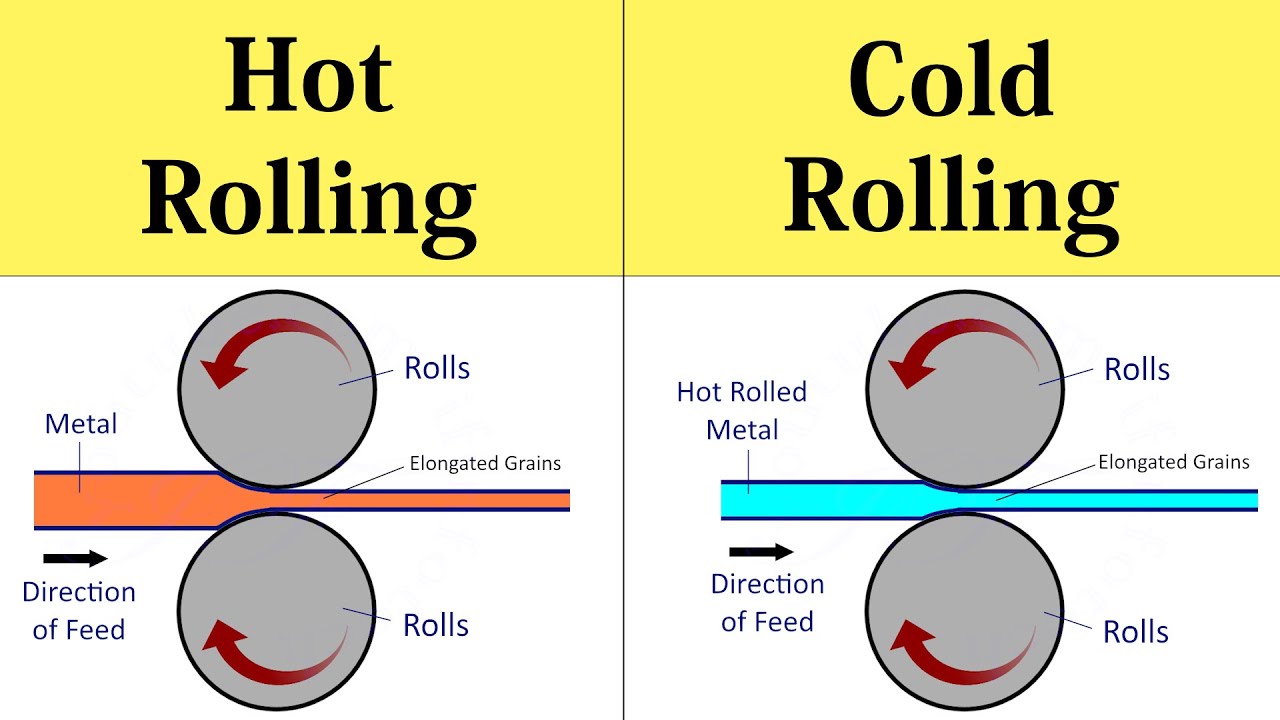

Now, this hot-rolled steel, it’s good for big things, like them beams they use to build houses and bridges. Big and strong, that’s what it is. They say it’s not as pretty as that cold-rolled stuff, but it’s strong, ya know? Cold-rolled is for smaller, finer things, like little parts in your car maybe. But we’re talkin’ about the hot-rolled stuff here.

So, they got these machines, rollin’ mills they call ‘em, and they squeeze and shape that hot steel into whatever they need. It’s loud and hot work, I bet. I wouldn’t wanna be anywhere near those machines when they’re workin’!

This whole rollin’ thing, it ain’t just some newfangled idea neither. People been doin’ this for a long, long time. Maybe not with machines like these, but they always been findin’ ways to shape metal. But now, they got these big ol’ factories that can do it fast and make lots of it. Good for buildin’ things, that’s for sure.

And let me tell ya, that hot-rolled steel, it’s everywhere. You just gotta look around. Those big buildings downtown? Probably got hot-rolled steel in ’em. That bridge you drive over? Hot-rolled steel. Even your car, got some hot-rolled steel in it somewhere, I bet. It’s what keeps things standin’ up strong, ya know?

So that’s the gist of it. They heat it up real hot, squeeze it through rollers, and make it into whatever shape they need. It ain’t rocket science, but it sure is important. Without it, we wouldn’t have half the stuff we got today. That’s for sure. Strong and sturdy, that’s what hot-rolled steel is all about.

They talk about “geometry” and “size”, that’s just fancy talk for makin’ it the right shape and how big it needs to be. It’s all part of the same thing, gettin’ that steel just right for whatever job they gotta do. And they do a lot of jobs with hot-rolled steel, I tell ya, a whole lot of jobs.

Tags: steel, hot rolling, process, manufacturing, metal forming, steel production, rolling mill, hot-rolled steel