Now, let me tell you a bit about rolled steel tubes. You know, these tubes ain’t fancy, but they sure come in handy for a lot of things. Rolled steel tubes come in two main types: hot-rolled and cold-rolled. Each one is rolled up a bit different, and it makes a difference in how they work and what folks use ‘em for.

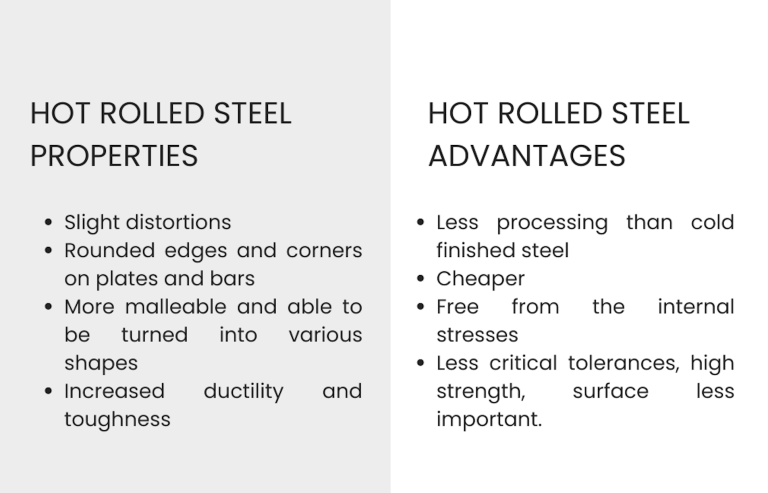

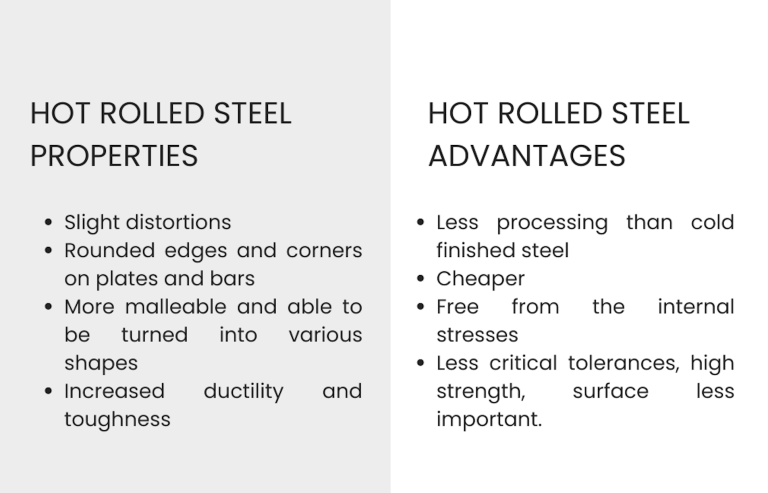

First off, hot-rolled steel tubes – these are the ones where they heat the steel up real high, over 1,700 degrees Fahrenheit! That makes the steel soft enough to roll out easier, so they can make bigger sizes and thicker walls with it. Now, because it’s done hot, the surface ends up a bit rough, but folks don’t mind that much if they’re just using it for strong parts like construction frames or in big ol’ machines. It’s tough, it’s durable, and for stuff that doesn’t need to be all that pretty, hot-rolled steel does the trick. Some folks even say it’s got better machineability, so it’s easier to cut, bend, and shape into whatever shape you need.

Now, cold-rolled steel tubes – well, that’s a whole other story. These get rolled out without the high heat, which helps make ‘em real precise. When they roll it cold, the steel doesn’t get all warped and lumpy. Instead, it keeps its shape better, so the size and thickness are just right. Because of that, cold-rolled tubes end up looking smoother and more polished. They’re more suited for things where you need ‘em to look nice and fit just right, like car parts or furniture frames. They’ve got that neat, clean finish folks want, especially when they’re working on stuff people see every day.

So, let’s say you’re trying to pick between these two for a project. Here’s what it boils down to:

- If you’re needing something strong, easy to shape, and you don’t mind it looking a bit rough, hot-rolled steel tubes are probably the way to go.

- If you want something that’s smooth, looks good, and has precise measurements, then cold-rolled steel tubes might be just the thing.

Another thing about cold-rolled steel, folks like to use low-carbon steel for it, since that makes it even smoother and easier to handle. Now, this low-carbon steel is real good for when you need a clean, nice look and the strength ain’t as important. You’ll often see it used in places like car body panels and door frames where you need things to fit just right and look clean. They don’t need to be heavy-duty, just reliable and pretty.

But for the real heavy lifting, you’d go with hot-rolled steel. It’s stronger, thicker, and can handle rougher conditions. It’s like the workhorse of steel – maybe not the prettiest, but gets the job done. That’s why folks choose it for things like building structures or even in agriculture equipment where strength matters most.

When you’re looking to buy rolled steel tubes, you got options all over. Places like Lowe’s got ‘em, or you can even check online for all sorts of sizes and thicknesses. Some companies even sell these in bulk, so if you’re needing a lot for a big project, you’re set. They got round tubes, square tubes, and even rectangular ones, depending on what you need. And, since each project’s different, you’ll find tubes with all kinds of wall thicknesses and finishes. Just make sure to pick the one that suits your work best.

All in all, rolled steel tubes may look simple, but picking the right one for the job sure makes a difference. Whether you go for hot-rolled or cold-rolled, each type’s got its own charm. Just figure out if you need that strength and durability or if a smoother, more polished look is what you’re after. Once you get that right, you’ll be ready to go.

Tags:rolled steel tubes, hot-rolled steel tubes, cold-rolled steel tubes, steel tubing, low-carbon steel