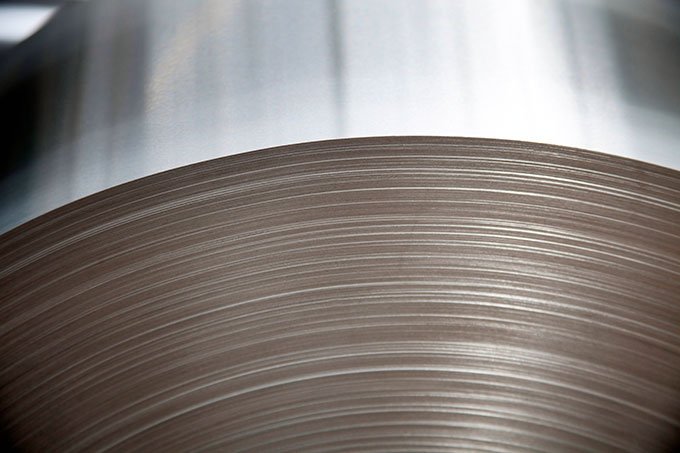

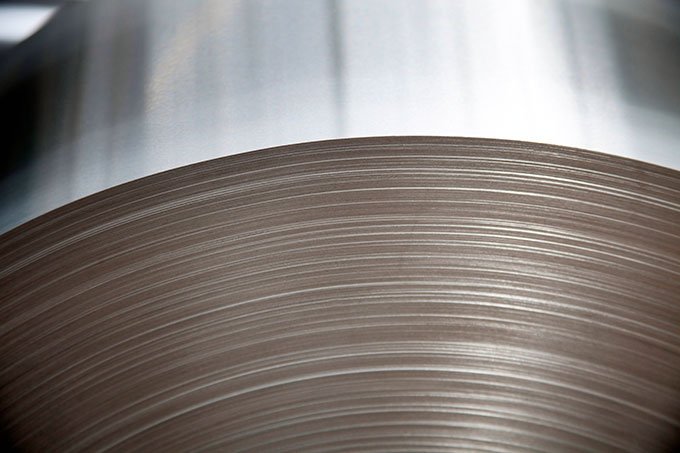

You know, this aluminized steel, it ain’t just some fancy talk. It’s basically steel covered up in aluminum, like giving it a protective jacket. Now, why would they do that, you ask? Well, when you put that aluminum layer on steel, it keeps it safe from rusting, breaking down, and all that trouble. Steel alone, it’s strong, sure, but it don’t stand a chance with too much heat or wet. So, this aluminizing thing, it’s like armor for the steel.

Now, how they do this aluminizing? Real interesting, it is. They don’t just slap on some aluminum paint or stick a foil around it. Nope, they got to melt down that aluminum, or even turn it into vapor, and then get it all soaked into the steel surface. This way, it don’t just sit on top; it becomes part of the steel itself. That makes it extra strong and reliable, ‘specially in hot places like ovens or even some big factory machines.

Uses of Aluminized Steel

There’s all sorts of places you find aluminized steel in nowadays:

- Kitchen Ovens: Yep, next time you roast a chicken, that oven might be lined with aluminized steel. Keeps the heat in, and don’t break down under high temperatures.

- Car Mufflers: Ever notice them pipes under the car? A lot of them are aluminized. Keeps ‘em from rustin’ and gettin’ holes, even in rain or snow.

- Industrial Equipment: In factories, all those big machines that heat up like nobody’s business? Aluminized steel’s their best friend.

Thing is, this aluminized steel ain’t cheap, but boy, does it last. They use it on things that need to take a lot of heat, or might end up sittin’ outside in all sorts of weather. Without the aluminum, that steel would be rustin’ and fallin’ apart. But with it? Stays strong and good as new for years.

Why Aluminized is Better

You see, steel by itself is tough, no doubt. But the weather, the heat—it don’t take long before it starts showing its age. Rust creeps in, then you got all these holes, and soon enough it’s time to toss it out. Aluminum, though, it’s got that special knack for keeping things safe. When you add that aluminum to steel, well, you get the best of both. Strong as steel, but now it’s also rust-resistant, heat-resistant, and durable as anything.

And you know what else? Aluminized steel even looks good. Shiny, smooth, not that rough, flaky mess that some old steels get. Makes it popular for all kinds of things, even stuff around the house where looks matter. In the kitchen, in heating ducts, all over the place.

Aluminizing Process

Now, the way they make this aluminized steel, that’s some process. They can do it two ways. One is dipping it, kind of like how you dip an apple in caramel. They dip the steel into melted aluminum and then pull it out, and once it cools, it’s got that nice aluminum coating. The other way is called vaporizing. They put the steel in a room full of aluminum vapor, and it just soaks in. Either way, that aluminum don’t come off easy. It sticks tight.

Advantages of Aluminized Steel

- Corrosion Resistance: No need to worry about rust eating away at it.

- Heat Resistance: It holds up in the heat, so good for ovens, mufflers, and factories.

- Longevity: Lasts a long, long time, so worth the cost.

So, next time you see aluminized steel, think about how it’s more than just shiny metal. It’s tough, reliable, and made to handle whatever’s thrown at it. With that aluminum coating, it’s like a hardworking piece that just keeps on going. And that’s why folks keep using it, year after year.

Tags:[aluminized steel, aluminum coating, corrosion resistance, heat resistance, metal durability, aluminizing process, industrial uses of aluminized steel]