Alright, let’s talk about this cold rollin’ thing, ya know? It’s like when they squish that metal real good, but not when it’s all hot and bothered. They do it when it’s, ya know, cool as a cucumber, or maybe just a little bit warm.

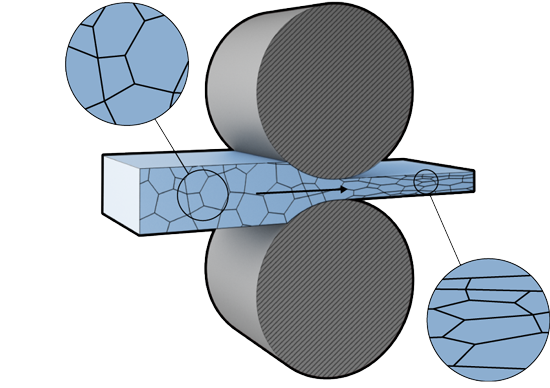

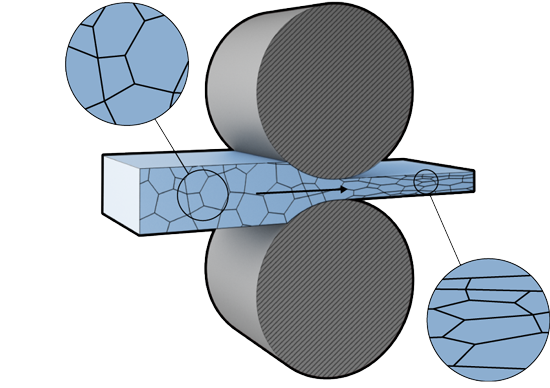

What’s this cold rollin’ all about then? Well, it’s like this. They take that metal, see, and they shove it through these big rollers. Like, real big and heavy. And them rollers, they squeeze the metal, make it thinner and tougher. It’s like when you knead dough, but way, way harder. They do it to make the metal stronger, ya know? So it don’t bend and break so easy.

They use this cold rollin’ for all sorts of things. I heard they use it for makin’ them metal sheets they use for buildin’ stuff. And for makin’ them wires and pipes that bring the water and ‘lectricity into our houses. It’s important, ya know? Like, real important.

- Stronger Metal: When they cold roll that metal, it gets real strong. Tougher than a boiled owl, I tell ya.

- Smooth Finish: And it makes it all smooth and shiny, too. Not all rough and bumpy like some of that other metal you see.

- Thinner Pieces: They can make the metal real thin with this cold rollin’, too. Thinner than a pancake, sometimes.

Now, they say there’s this other thing called hot rollin’. That’s when they do the squishin’ when the metal’s all hot and bothered. But this cold rollin’, it’s different. It makes the metal stronger and smoother, ya know? It’s better for some things.

Where do they use this cold rollin’ stuff? Well, just about everywhere, I reckon. I heard they use it in cars, makin’ them strong and safe. And in them airplanes that fly up in the sky. Can you believe that? Metal flyin’ in the sky! They also use it for makin’ all sorts of things around the house, like fridges and washing machines and such. Even them little cans of beans you buy at the store, they probably used cold rollin’ for that metal, too. It’s everywhere, I tell ya. Everywhere!

This cold rollin’, it’s a big deal, ya know? It’s how they make a lot of the metal stuff we use every day. Without it, things would be a whole lot different, I reckon. We wouldn’t have all them strong and shiny metal things we got now. So, next time you see a metal thing, just remember, it probably got cold rolled at some point. It’s important to remember these things, ya know?

And lemme tell ya, it ain’t easy work, this cold rollin’. Them machines are big and loud and dangerous. You gotta know what you’re doin’, or you could get hurt real bad. It takes strong folks and smart folks to make this cold rollin’ happen, ya know? It ain’t just pushin’ a button and poof, ya got metal. It’s a whole process, a real hard process.

So there ya have it, that’s the lowdown on cold rollin’. It’s about makin’ metal stronger, smoother, and thinner. And it’s used for all sorts of things, from cars to cans. It’s important stuff, ya know? Real important.

And another thing, this cold rollin’ ain’t somethin’ new, ya know? They been doin’ it for a long time, I reckon. Maybe not exactly the same way they do it now, with all them fancy machines. But they been findin’ ways to squish metal and make it stronger for ages. It’s just somethin’ people do, ya know? We always tryin’ to make things better, stronger, more useful.

So, yeah, that’s cold rollin’ for ya. It ain’t rocket science, but it’s important work. And it makes the world a better place, I reckon, with all them strong and shiny metal things. Just remember that next time you’re usin’ somethin’ made of metal, alright?

Anyways, that’s all I got to say ‘bout this cold rollin’ business. It’s important, it’s everywhere, and it ain’t easy. But it sure is useful. Now, if you’ll excuse me, I gotta go check on my chickens.

Tags: [Cold Rolling, Metal Processing, Steel, Metal Forming, Applications, Manufacturing]