Well, let me tell ya somethin’ about this sheet metal and plate metal stuff. Folks make it sound all fancy, but it ain’t rocket science, you know? It’s all about how thick the darn thing is. Yep, that’s the main thing to remember. Thickness, that’s the word!

Now, they got these numbers and all, like 0.006 inches or 0.250 inches. Don’t get your head spun around. Just think of it like this: sheet metal is the thin stuff, you know, like the kind you can bend pretty easy. Plate metal, that’s the thick, tough stuff. Like, if you wanna build a real sturdy thing, you’d use the plate.

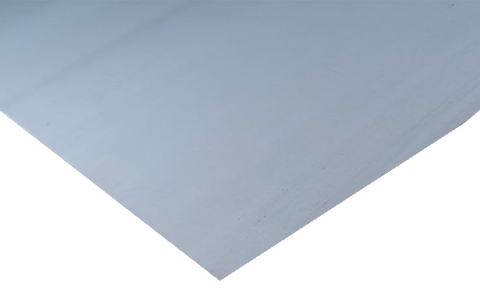

- Sheet metal: Thin like paper, well, not paper exactly, but you get the idea.

- Plate metal: Thick like a good ol’ cast iron pan.

They got these gauges too, but don’t worry too much about that. Just remember, higher the number, thinner the metal. It’s like, the more you gotta squint to see it, the higher the number. Makes sense, right? They use this stuff for all sorts of things. Sheet metal, that’s for roofs and gutters and such. Plate metal, that’s for big ol’ machines and buildings. Stuff that needs to hold up, you know?

So, you’re lookin’ at a piece of metal, and you’re wonderin’ if it’s sheet or plate? Just look at how thick it is. If it’s real thin, like, thinner than a quarter, then it’s probably sheet metal. If it’s thick like, well, thicker than a few quarters stacked up, then it’s plate metal. Simple as that.

Some folks say if it’s thicker than a quarter of an inch, it’s plate. Others say it’s gotta be a bit thicker, like a quarter of an inch and a hair more. Don’t get too hung up on the exact numbers. Just remember, thin is sheet, thick is plate. That’s all there is to it, really.

Now, they measure this thickness in inches mostly, sometimes in millimeters if they’re feelin’ fancy. But inches is what most folks use around here. So, if someone’s talkin’ about 0.024 inches, they’re talkin’ about sheet metal, real thin stuff. If they’re sayin’ 6 millimeters or more, that’s plate, the thick stuff.

You know, it’s like bakin’ a pie. You want a thin crust, you use a thin sheet of dough. You want a sturdy bottom, you make it thicker, like a plate. Same kinda idea with metal, you see? Thin for light stuff, thick for heavy stuff.

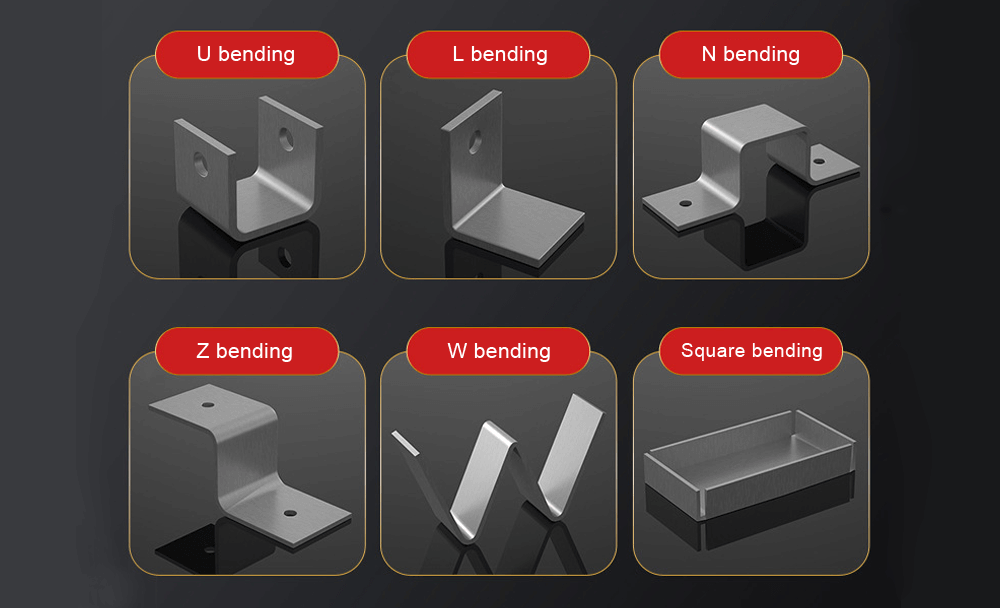

Sheet metal is easy to work with, they say. You don’t need to be a big strong fella to bend it and shape it. Plate metal, that’s a different story. You need some real muscle or some fancy machines to get that stuff movin’. It’s heavy, you know?

So, next time you hear someone talkin’ about sheet metal versus plate metal, don’t go gettin’ all confused. Just remember what I told ya. Thin is sheet, thick is plate. And it’s all about how thick it is. That’s the long and short of it, plain and simple. No need to make it more complicated than it is.

And don’t let those fancy words fool ya. They might say “gage” or “gauge” but it all boils down to the same thing: thickness. Just like callin’ a soda “pop” or “coke,” it’s the same darn thing, just different words. So, keep it simple, and you’ll be just fine.

And one more thing, they use this sheet and plate metal for all sorts of things you wouldn’t even think of. Cars, airplanes, even your kitchen sink might have some sheet metal in it. Plate metal, that’s for the big stuff, like bridges and buildings. It’s all around us, you just gotta know what to look for.

So there you have it, the whole story of sheet metal and plate metal, told plain as day. Now you can go around tellin’ everyone you know the difference. And they’ll be impressed, you betcha. They’ll say, “Well, that fella sure knows his metal!” And you can just smile and say, “Yep, I do.” Because now you do. You know all about sheet metal and plate metal, and that’s somethin’ to be proud of. It ain’t easy keepin’ all this stuff straight, but you done it. Good for you.