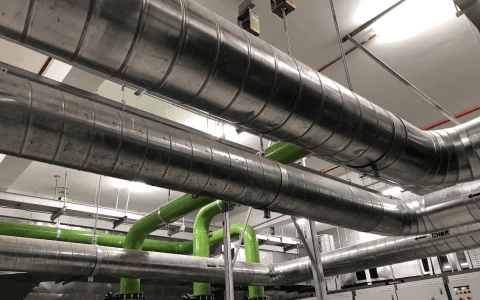

Rolled steel pipe, oh, it’s a type of pipe folks in the industry use a lot for big projects, like building bridges, laying down some deep water lines, or even big ole’ construction jobs. Now, this ain’t your regular little pipe – these rolled pipes are wide, and they’re tough, and they start from around 22 inches in diameter, sometimes going all the way up to massive 184 inches! Imagine that, big enough for some serious work!

So, what’s all the fuss about rolled steel pipe?

Well, let me tell you, rolled steel pipe is made in a way that’s different from other pipes. They take steel plates, roll ‘em up into what looks like cans, and then they weld those cans together – that’s what gets you one long piece of pipe. And because it’s welded real good along the seams, it’s sturdy enough to handle big pressures without busting open.

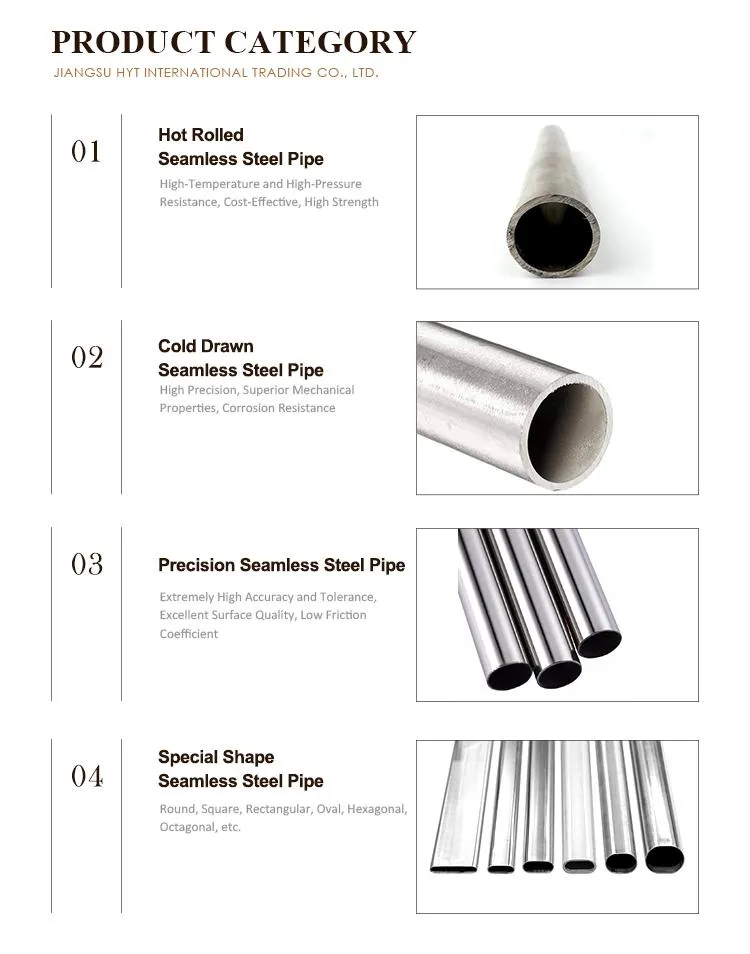

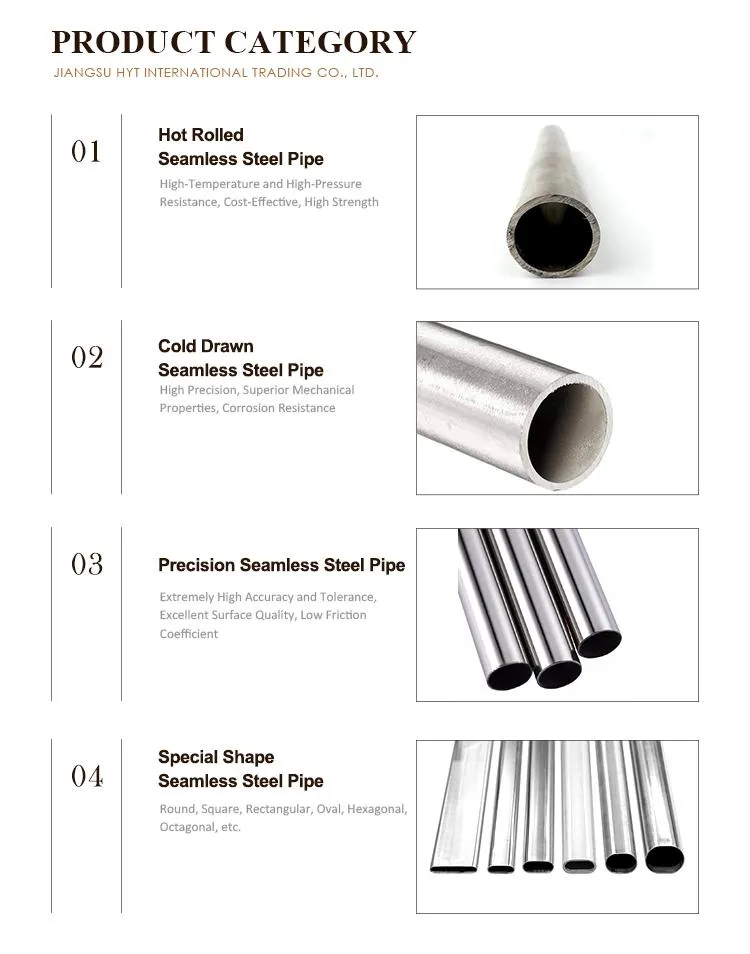

There’s hot rolled and cold rolled steel pipes, you know? Hot rolled pipes, they get made when the steel’s still all hot and easy to shape. They don’t fuss much about how smooth the surface is, just roll it while it’s heated. And then you got cold rolled ones, where they shape the pipe after it cools down a bit, making it smoother, but takes more effort. Folks say hot rolled pipes are tougher, but cold rolled pipes, well, they look nicer for when looks matter. You gotta pick what works best depending on the job.

Uses for Rolled Steel Pipe

Now, where you gonna see these rolled pipes being used? Oh, all over the place! Some folks use ‘em in the oil and gas industry – they’re perfect for carrying stuff deep underground or even across water. Other folks use these big pipes for piling, which is when you put the pipes down deep in the ground to keep structures steady. And then you got rolled steel pipes working as columns, like when they’re building those tall buildings. Some folks even use it to make machinery and equipment since it’s so durable.

Rolled Steel Pipe: The Making Process

Alright, let’s get down to how these pipes come to be. They start with flat steel plates, then those plates are bent up to make a “can” shape. Once the cans are ready, the seams are welded, and they do this over and over till you got yourself a long, thick-walled pipe. Those seams – they’re welded strong to make sure that pipe don’t burst or leak. This kinda welded pipe, it’s perfect for projects where you need something tough and thick.

For the folks wondering, “How thick are these pipes?” – it depends! Some jobs need thick walls to handle high pressure, while some just need a lighter wall. They can make rolled pipes in different thicknesses, fitting to whatever the project demands.

Hot Rolled vs. Cold Rolled: What’s the Big Difference?

Hot rolled pipes are the rough-and-tumble kind. They come out when steel is still hot, so it’s easier to shape, and usually a bit cheaper. But they’re a bit rough around the edges. Cold rolled, on the other hand, means they take cooled-down steel and roll it some more, making it a bit smoother and stronger. Cold rolled pipes are better for when the looks matter, like when you need something smoother and shiny. But they cost a bit more since they’re harder to make.

Why Choose Rolled Steel Pipes?

People pick rolled steel pipes ‘cause they’re big and strong. When you got a job that needs to hold up against water, dirt, and heavy loads, these pipes do the trick. Think about it – for stuff like bridges, you need pipes that won’t just give out. Plus, they can handle different weather conditions, which is good for pipelines that go through different climates. These pipes are also popular because they can be made in custom sizes, fitting exactly what a job might need, whether it’s big pipes or thicker walls.

Finishing Touches

Once rolled steel pipes are welded and done, some companies add a coating to make ‘em even stronger against rust and corrosion. When a pipe’s going under the ocean or buried in soil, it’s gotta be tough against all that water and dirt, and coatings help make ‘em last longer. They even test the pipes with pressure and bending tests, making sure each one’s ready to handle what the job throws at it.

Some Final Thoughts

So, that’s rolled steel pipe for ya! It’s big, it’s strong, and it’s got a whole bunch of uses in heavy-duty work. Whether you need pipes for piling, structural support, or water and gas lines, these rolled steel pipes stand strong. Just gotta pick the right size and type – hot or cold rolled – and you’re all set!

Tags:[rolled steel pipe, hot rolled steel pipe, cold rolled steel pipe, welded steel pipe, heavy-duty steel pipe]