Well now, let me tell ya a bit ’bout this thing they call deep drawing steel. Ain’t no fancy talk, just simple words for ya to get the idea. Now, deep drawing, it’s like shaping up steel into cups, cans, or them round things you see. Kinda like when ya roll out dough but instead, here it’s with steel sheets. Ya got a machine and a big ol’ punch that presses down on the steel, pushin’ it into a shape like a pot or pan. This here is called deep drawing ‘cause if ya go deep enough, it’s somethin’ special.

Now, ya might be wonderin’ what kinda steel folks use for this. Let me tell ya, it ain’t just any ol’ scrap steel. Usually, they use cold rolled low carbon steel. This kinda steel is easy to bend, so when the machine’s punch comes down on it, it don’t crack or get all messed up. That’s important, ya know? But it ain’t just steel they use. They got other metals too, like aluminum, brass, and copper, and they all got their uses dependin’ on what ya makin’. Aluminum’s good ’cause it don’t rust easy, and copper? Well, it’s a strong one, too.

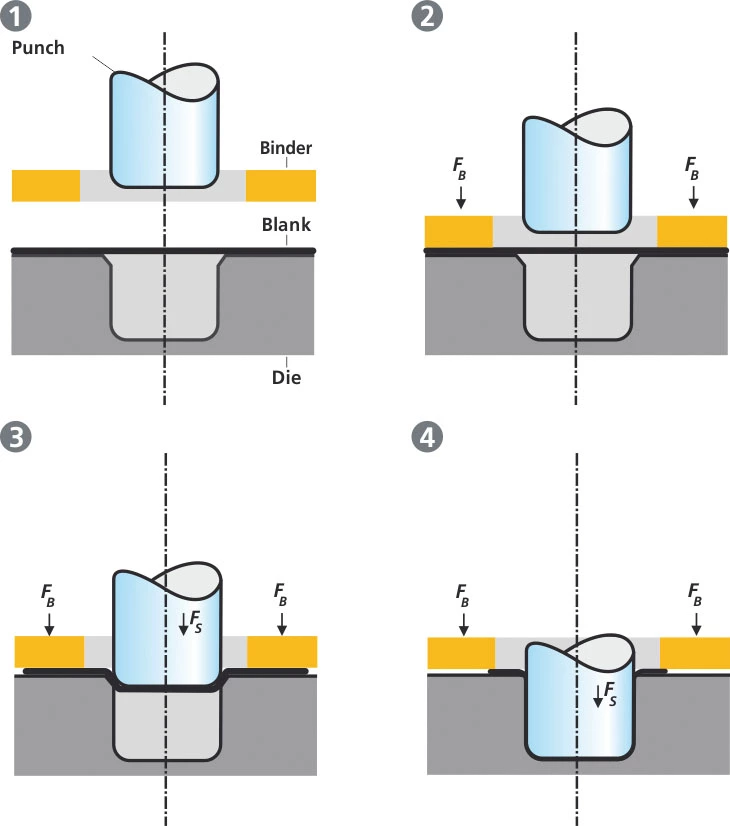

So how’s it work, you ask?

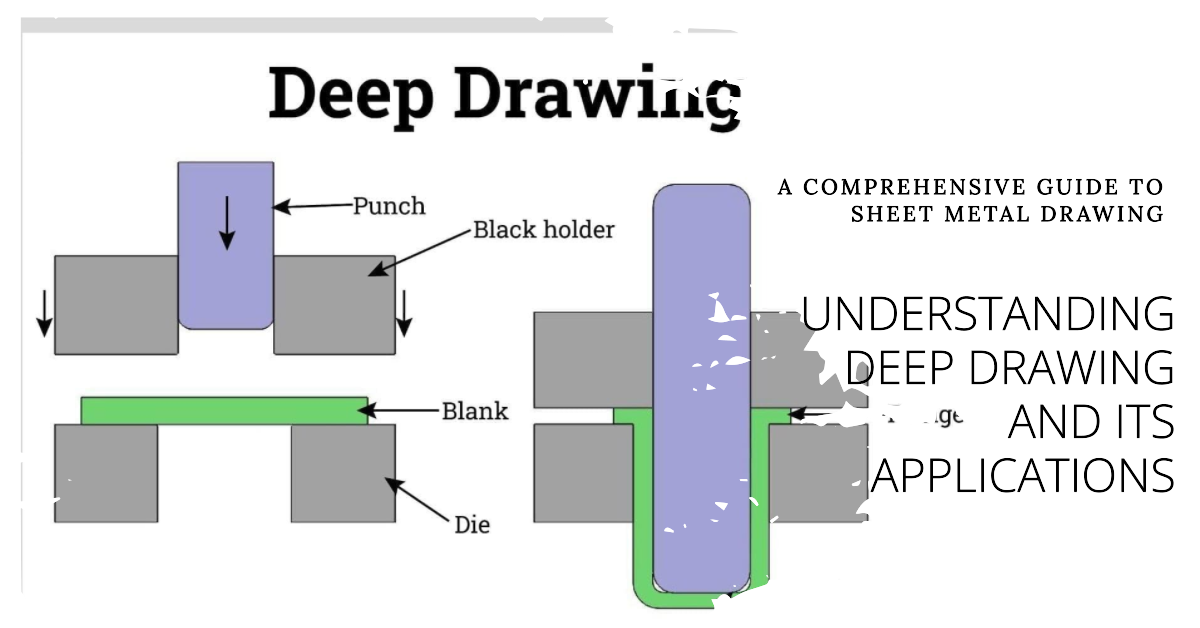

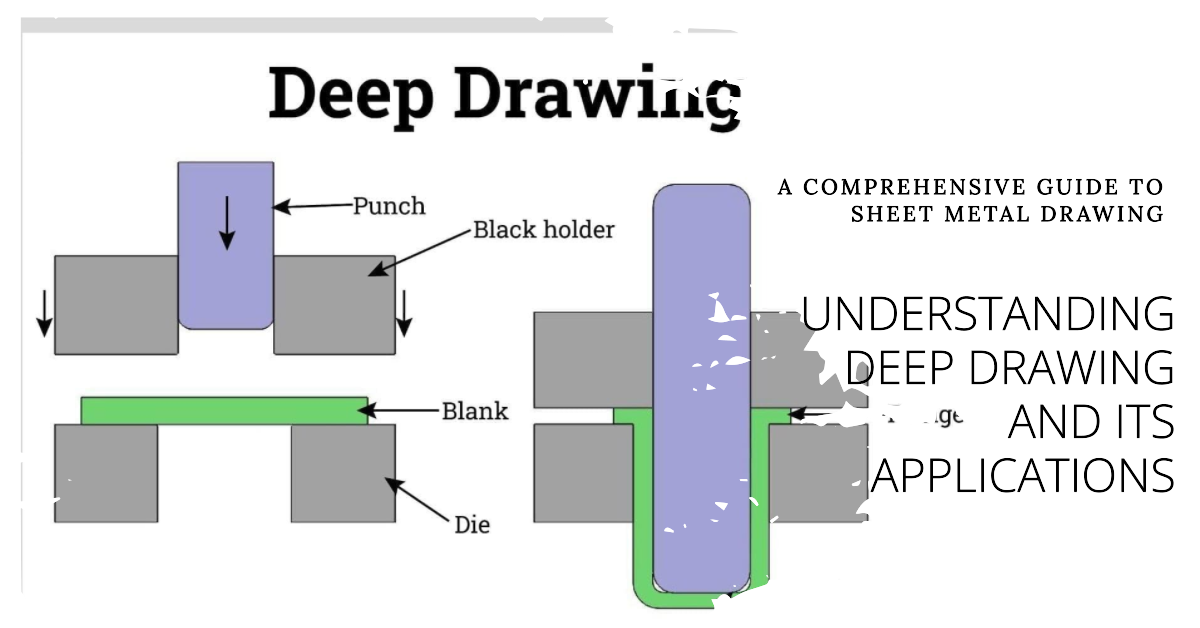

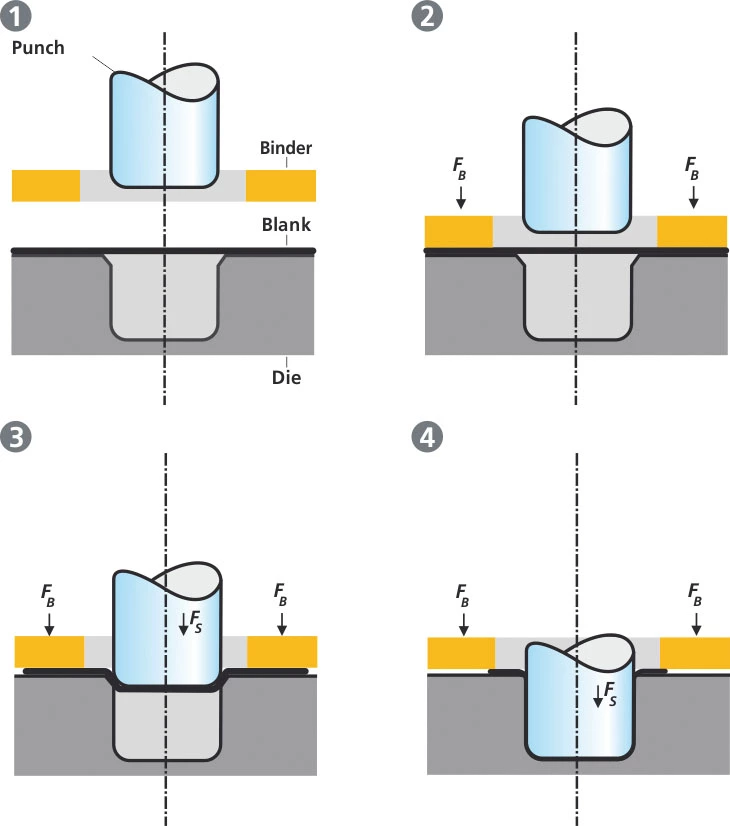

Alright, lemme break it down nice and easy. First off, they start with a flat sheet of steel. Then, this here punch tool comes down on it, squeezin’ that sheet into a die – a mold, kinda like makin’ cookies, but way tougher. This mold shapes the steel into what they need. And if they want it deep – I’m talkin’ deeper than it is wide – then they call it deep drawing. The machine has to press down hard and deep, so it don’t break the shape.

Now, it ain’t all easy, ya see. There’s things they gotta watch out for, like friction. The steel and the tool rub together, so it gets hot and could mess up the metal. That’s why they slather on a bunch of lubricant, kinda like greasin’ a pan so the cake don’t stick. They got special stuff for this, like heavy-duty oils or even certain chemicals that help the steel move smoothly without gettin’ stuck.

- Lubricants: Keeps it smooth, like oil on a rusty gate.

- Punch and die: That’s the tools doin’ all the heavy liftin’.

- Cold rolled low carbon steel: Best kind for this job, easy to shape.

So, whatcha end up with after all this punchin’ and squeezin’? Well, ya get all kinds of things! Ya got pots, cans, car parts and more. You name it. They even make parts for those fancy gadgets and machines. This here deep drawing steel’s used everywhere, from your kitchen to them big ol’ factories.

One last thing – the shape. Oh, they ain’t just makin’ circles all day. No sir, they can make rectangles, squares, and all sorts. But it takes a lotta work. Them complicated shapes, they need more tools and sometimes even different steps to get the metal just right. But when it’s done right, it’s sturdy, durable, and ready for just about anything.

So, that’s deep drawing steel for ya, plain and simple. Ain’t no rocket science, but it takes some know-how to get them sheets into shape without messin’ up. From car parts to kitchen things, all that stuff ya use daily probably came through deep drawing. And now ya know a bit ’bout how it’s all done!

Tags:[deep drawing steel, cold rolled steel, sheet metal forming, punch and die, metal shaping process]