Alright, so this here talk today, it’s all about cold drawn steel, you know? Now, this stuff, it’s got a bit of a special way it’s made, and it’s real good for all kinds of projects where you need a tough, straight piece of metal. Now, don’t think it’s like that hot steel you might picture fresh outta the furnace. Oh no, this cold drawn steel is worked on without heating up much, and that’s what makes it stand out. Let me tell you how it’s all done and why folks might want to use it.

First up, the process. See, cold drawn steel is made using something called a die. Now, what happens here is you take a piece of steel and shove it through a special kind of tool called a die, right? And as it squeezes through, it takes on the shape you want, and it gets real smooth. This is all done at room temperature, which is what they mean by “cold drawn.” Ain’t no fire or heat on this one, it’s just pulling and pressing through that die, like stretching dough through a rolling pin.

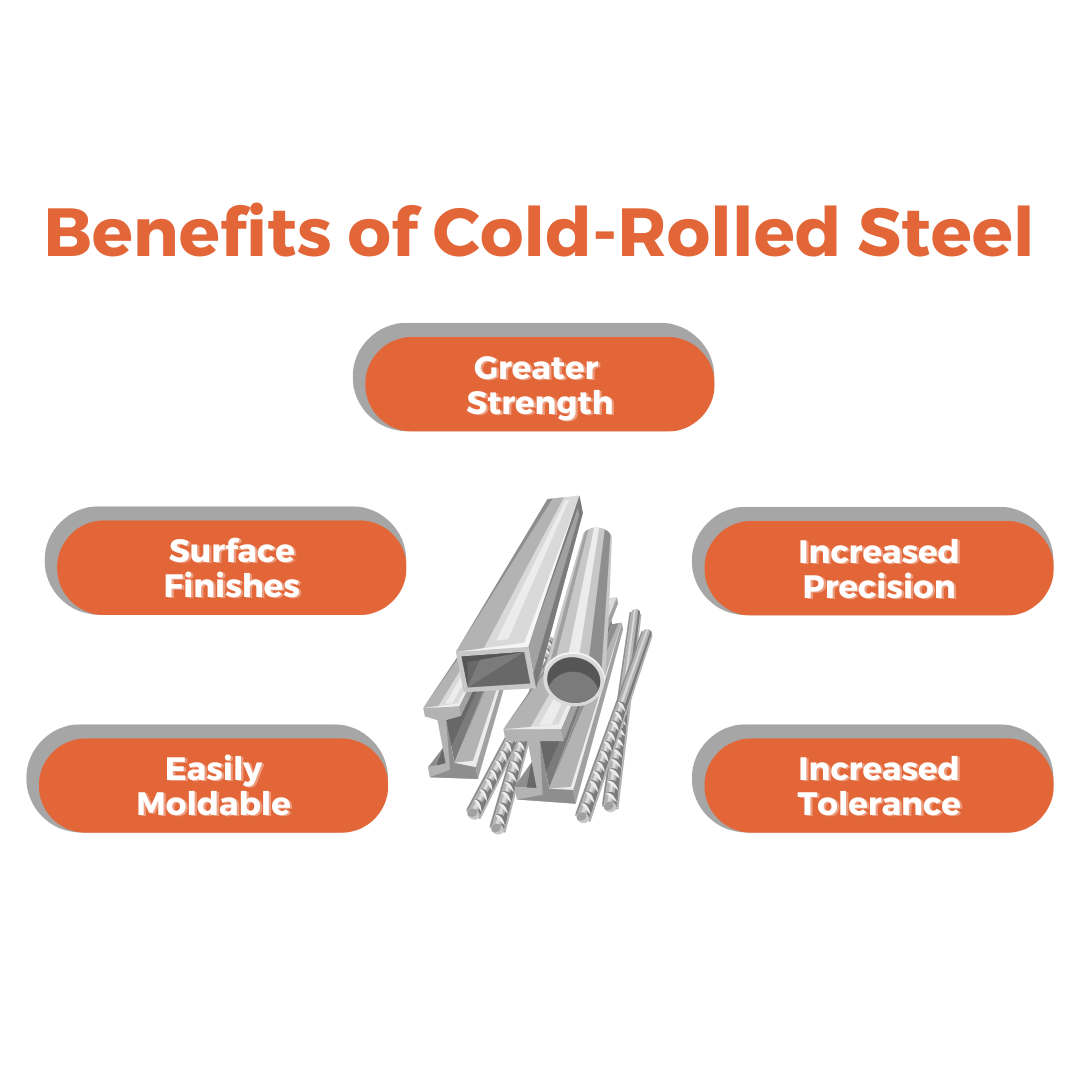

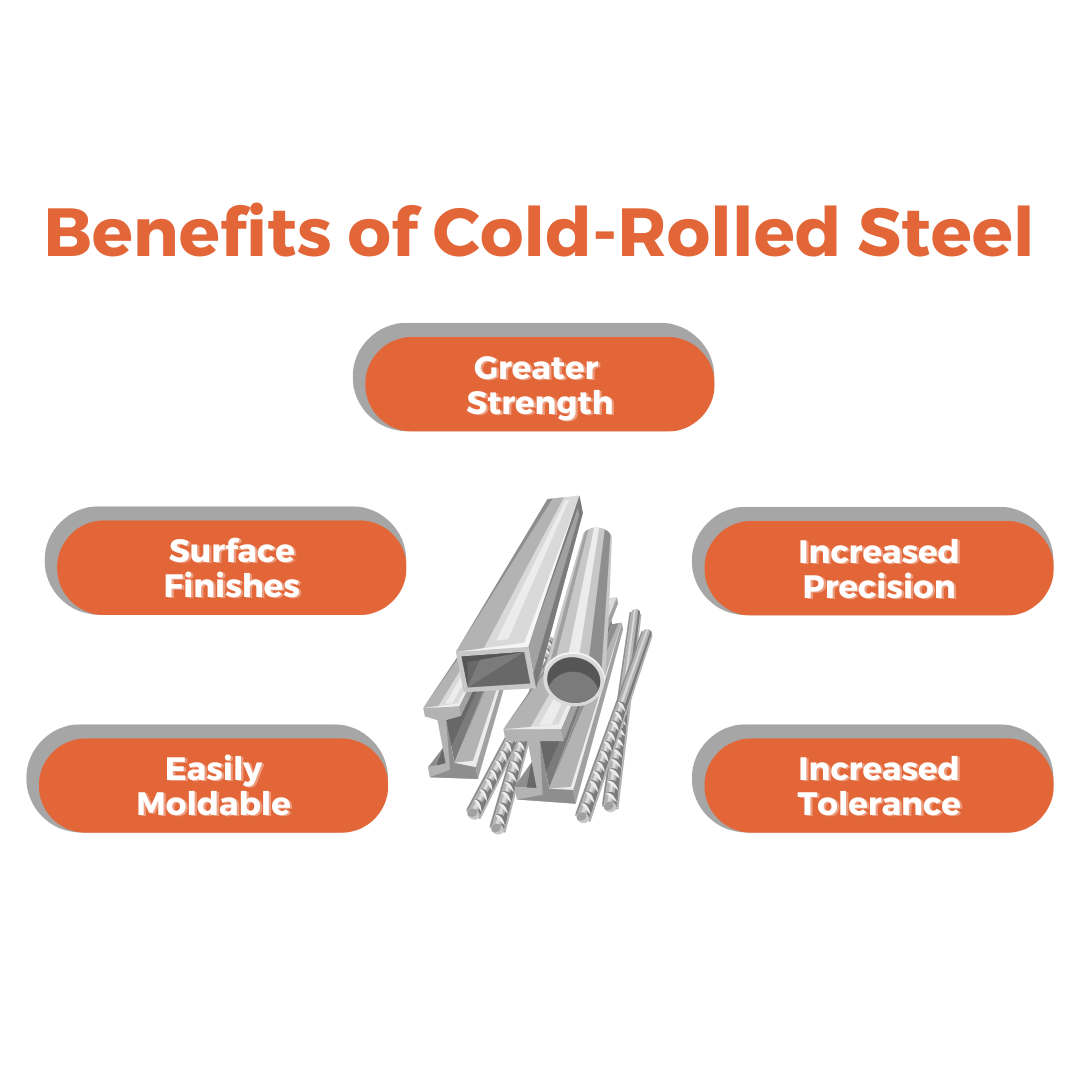

So, why bother with cold drawn steel when there’s other types out there? Well, that’s ’cause it gives you better strength and precision. Compared to the hot stuff, this one’s got better shape and better straightness. You know, when you’re building things, maybe some machinery parts or them long wires, this cold drawn steel won’t bend or give way too easy. Keeps its shape good and stays right where you need it.

- Better Strength: Now, if you’re thinking, “Why go through all that trouble?” well, cold drawing makes the steel stronger. Since it’s not heated, it holds up real good when you’re putting it to work.

- Precision: Cold drawn steel is known for its straightness. You don’t have to worry about it twisting or bending. It’s perfect if you need an exact size.

- Surface Finish: This process also makes the surface nice and smooth. So, if you’re looking to build something that looks neat and tidy, this one’s for you.

When it comes to types of cold drawn steel, most folks go for either rods or bars. These are the most common shapes, ’cause they’re easy to fit into all sorts of machinery or structures. Rods are good if you need something small and sturdy, while the bars are for bigger builds. And then there’s also different types of steel grades, but one of the common ones is called 1020 carbon steel. It’s got just the right mix of carbon in it to make it strong, but not too brittle. Nice and reliable, you see?

Alright, let’s chat a bit on where cold drawn steel is used. This type of steel shows up in all sorts of places, like in car parts, construction, even in farming tools. Say you’ve got an engine or some mechanical part that needs to be just right in size—cold drawn steel is your best friend there. It’s also popular for making shafts and gears, anything where that exact size and shape makes a big difference in how it works.

Now, the benefits of cold drawn steel over the regular hot steel is real clear when you see how it handles under pressure. Since this type is drawn at room temperature, it doesn’t get all soft and wobbly. Keeps its shape better, and if you’re making parts for machines, that’s a big deal! Plus, with cold drawn steel, you get less waste. When you’re shaping it, you don’t need to shave off as much, so you’re not left with as many scraps at the end.

In fact, they got all kinds of uses for this type of steel, and here’s a few examples where it shines:

- Automotive Parts: Engines, shafts, all that moving stuff in a car can use cold drawn steel for strength and size.

- Construction: Anywhere that needs steel bars or rods, cold drawn steel does the job.

- Manufacturing: Gears, axles, and other parts that gotta be exact sizes, that’s where cold drawn steel fits in real good.

So, end of the day, cold drawn steel might not be something you see every day, but it sure does its job in making things that last. It’s strong, stays straight, and has a good, clean surface that’s ready for action. Next time you hear about steel rods or bars, think about how cold drawn steel might just be what’s keeping things strong and steady.

Tags:[cold drawn steel, cold working, steel manufacturing, cold drawn bar, 1020 carbon steel]