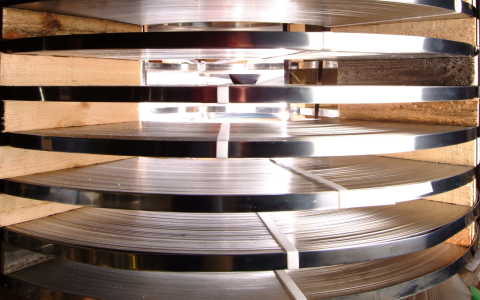

Coil slitting, this ain’t no fancy thing, I tell ya, it’s just cuttin’ big ol’ metal coils into smaller strips, simple as that. They take this big master coil—could be steel, aluminum, you name it—and run it through some real sharp blades, them circular ones, like giant scissors but meaner. This cuttin’ splits the big coil into narrow pieces, and each of these pieces gets called a “mult.” These mults, well, they’re all sized up just right for whatever the job needs, width and weight and all.

Now, what’s the point, you might be wonderin’? Well, turns out, folks need all sorts of shapes and sizes for metal. Think of car parts, HVAC pipes, even them medical things—they all need bits of metal that ain’t too wide or too thick. That’s where this slittin’ business comes in handy. By cuttin’ them coils just right, them companies can use the strips for all kinds of fancy stuff.

How Does Coil Slitting Work?

Alright, let’s talk about the process a bit. Imagine this, you got a big ol’ coil that’s too wide for what you need, so you feed it through a machine with a bunch of knives, these here rotary slittin’ knives. Now, these ain’t your kitchen knives; they’re sharp as can be and cut through metal like it’s butter. As the coil runs through, them blades do their thing, slicin’ it down to the width needed.

But here’s the kicker—you gotta know your metal, right? Can’t just go slicin’ any old steel. Steel grade, thickness, all that needs attention, else you end up with burrs, wavy edges, or even bends in the strip. I reckon nobody wants sloppy cuts, so you best go to someone who knows what they’re doin’. Bad slittin’ leads to all sorts of trouble, like knife marks and edge wave, and that ain’t good for nobody’s work.

Why Do We Need Coil Slitting?

- Automotive: Car parts, like trims and brackets, need narrow coils that fit their specific shape. Slittin’ lets ‘em get just what they need.

- HVAC: Them ducts and pipes need strips that fit right. With coil slittin’, they get it the exact size, no messin’ around.

- Electronics: Little gadgets and gizmos need metal pieces cut just right, and slittin’ handles that better than any old method.

- Appliances: Your fridges, ovens, washers—all got metal bits, and coil slittin’ makes those parts happen.

Now, all this slittin’ might sound like a quick thing, but it’s a whole process with attention to detail. They gotta check each slit coil after, make sure edges are clean, no jagged bits or waves. Each mult coil gets checked, then packed up all nice and neat, ready to head off to wherever it’s needed.

Common Problems in Coil Slitting

Let me tell ya, if this slittin’ ain’t done right, you end up with all kinds of issues. A bad slittin’ job, well, you got burrs, wavy lines, and sometimes the metal’s even bent funny. Ever seen a crossbow? Metal can twist up like that if the slittin’ ain’t spot-on. And then there’s somethin’ called camber, like when the strip ain’t straight as it oughta be. That’s why folks pay top dollar for folks who know their metal and got good tools for the job.

Choosing the Right Coil Slitting Service

Now, you might be thinkin’, “Well, ain’t any ol’ shop good for slittin’?” Nope! Takes real skill and quality gear. A good slittin’ shop’s gonna use proper, high-quality tools, makin’ sure that every coil comes out lookin’ sharp, edges clean and ready to go. So, if you’re in need of some slittin’ done, best find yourself a service that knows their way around metal and runs them slittin’ knives smooth and clean.

In the end, coil slittin’ is a handy trick of the trade, takin’ them big rolls of metal and makin’ ‘em into useful bits for all sorts of industries. So next time you see a car trim or a piece of ductwork, remember that behind it was probably a big ol’ coil that got sliced down just right. That’s coil slittin’ for ya!

Tags:[coil slitting, metalworking, automotive industry, HVAC, electronics, manufacturing, coil splitting process]