Now, let’s talk about slit coils, a type of steel folks use all over, especially in building and making things. Now, some of you might be wondering, “What’s so special about these slit coils?” Well, I’m here to explain it in a way that even your grandma back in the village could understand.

What is a Slit Coil, Anyway?

Alright, let’s start with the basics. So, a slit coil is like a big roll of steel that’s been cut down into smaller strips. Imagine you got a huge roll of cloth, but you don’t need the whole thing, you just want a few strips to make a quilt or something smaller. So, you take scissors, or here, they use big fancy machines called slitting knives, and cut the big roll into narrow coils. These smaller ones? They’re called “mults.”

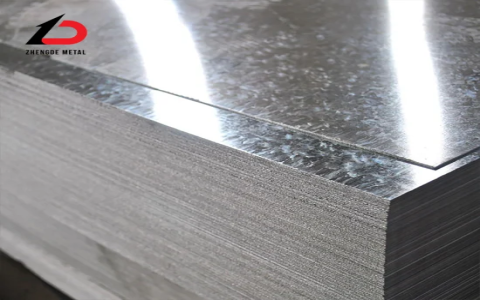

These slit coils come from big sheets of metal, usually carbon steel, stainless steel, or even coated steels like galvanized steel. It’s not just a random cutting job; they make sure each coil is exactly the width you need, so there’s not too much wastage.

Why People Use Slit Coils

Now, why do people want these slit coils? Well, they save time, money, and materials. For factories, getting the steel already in the right size is a big help, no need to go cutting again. They can just start using it right away. These coils are super helpful in making all kinds of things, from parts in your car to the kitchen sink or even big building projects. Anything that needs steel strips can use these coils!

- Hot Rolled Slit Coils: These ones are made by rolling steel at high temperatures. They’re tough, but the finish might look rough. People use them where looks don’t matter as much.

- Cold Rolled Slit Coils: These are smoother and have a nice, clean finish. They’re good for parts that people will see, like appliances or furniture.

- Galvanized Slit Coils: These ones have a coating on them that keeps them from rusting. Real handy for stuff that’ll be outside, like fences or sheds.

The Coil Slitting Process: Simple but Precise

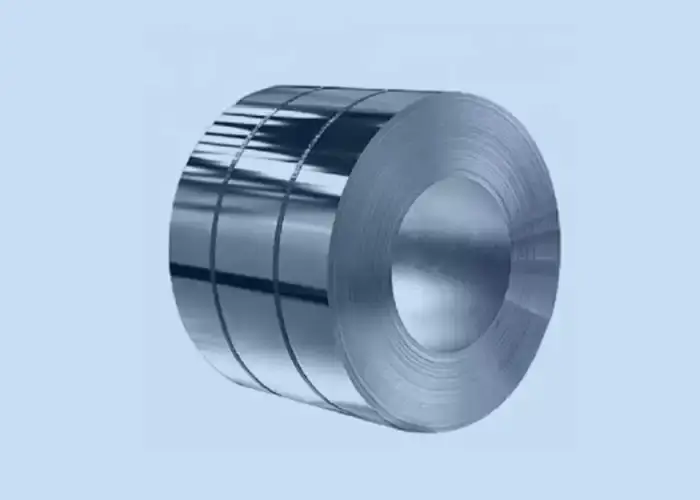

So, how do they actually make these slit coils? They start with a big, wide coil of steel called a “master coil.” Then it’s fed into a machine with these big knives that are set to the right widths. The machine cuts the coil in one go, and out come these narrow coils, each just the size the customer needs. Real precise work!

The companies that do this are experts. They make sure the coils are all cut to the right width, no matter how narrow or wide you need. And they even keep tolerances—fancy talk for saying the coils are super accurate. They don’t just eyeball it, no sir! They make sure every coil meets the standard.

Benefits of Slit Coils for the People Who Need ‘Em

People order slit coils because they’re easy to use. Imagine if you had to cut every single strip yourself—would take forever, wouldn’t it? And who’s got time for that? With these coils, they’re ready to go, no fussing. Companies can save money because they don’t have to pay extra for workers to cut the steel. Plus, they can order the exact size, so there’s less waste. Ain’t nobody got time or money to waste on extra material these days.

And these slit coils aren’t just for one kind of industry either. They’re used in automotive (like making car parts), construction (building frames or structures), furniture (like metal parts in chairs and tables), and even appliances (think of the shiny metal in your fridge). These coils are versatile, which is why so many industries want ’em.

Popular Sizes and Customization

Now, you might think all slit coils are the same size, but that’s not how it works. Customers can order the coils just how they like. They can choose the width and weight that fits their work. Some folks need thin strips, maybe a quarter-inch, while others want them a few inches wide. And they can make the coils as heavy as the customers want, too.

How Slit Coils Make Manufacturing Easier

At the end of the day, these slit coils are a time-saver. Businesses don’t have to keep big, clunky machines to cut the steel themselves. They can just order what they need, already sized and ready to go. These companies making slit coils got it down to an art, and each coil is packed up neat and safe, ready to be shipped out. It’s like getting a custom-cut piece of cloth, all neat and tidy, ready for sewing.

Final Thoughts on Slit Coils

So there you have it. Slit coils are just plain useful. They’re custom-sized, they save on waste, and they’re easy to use. They might just look like strips of metal, but for companies all around, they’re a big deal. If you’re in the business of making things with steel, getting slit coils is like getting a head start, saving time and trouble down the line.

That’s the beauty of slit coils – simple, practical, and ready to go!

Tags: [slit coils, coil slitting, steel processing, hot rolled coils, cold rolled coils, galvanized coils, manufacturing steel]