Hey, let me tell ya all about this rolled sheet metal thing, ya see. It’s all about takin’ big ol’ hunks of metal and pressin’ ‘em down flat like one of them pancakes ya flip on a griddle. Now, there’s a couple ways to do it, but the big thing folks care ‘bout is hot rolled and cold rolled, ya see?

Hot Rolled Sheet Metal

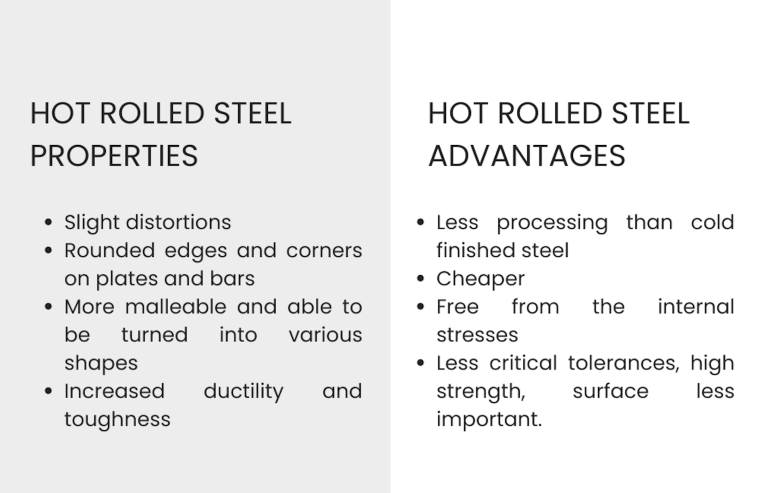

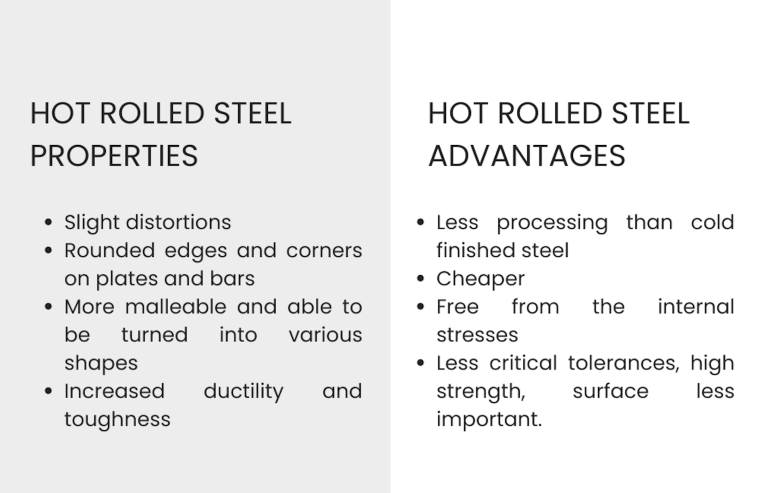

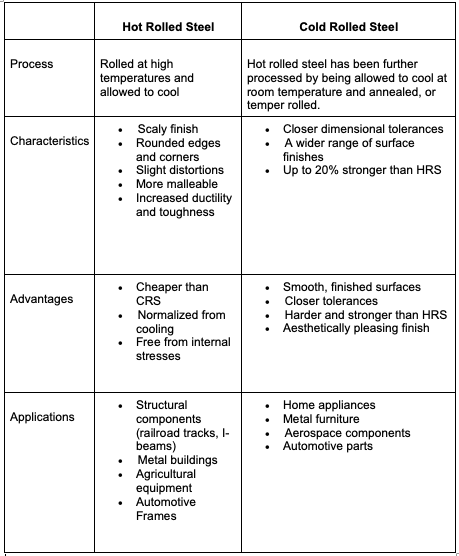

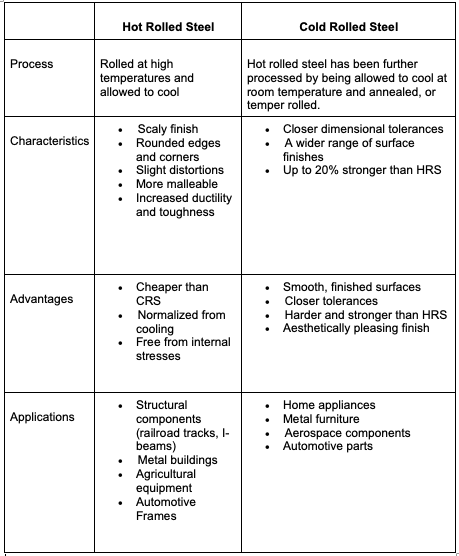

Now, this hot rolled metal stuff, well they take that metal and get it all hot – hotter than a campfire, over 1,700 degrees! Gets so hot ya can almost see through it, like the steel done turned to liquid or somethin’. So, while it’s all soft like that, they roll it and squash it into big sheets. Real handy for makin’ big ol’ things like bridges and cars, ya know? Hot rolled metal comes out kinda rough, like the top of my ol’ farm road. But it’s strong and cheap, so folks don’t mind that texture if they just need somethin’ tough.

Cold Rolled Sheet Metal

Now cold rolled, that’s a bit different. They take that same metal, but instead of heatin’ it up to make it easy to squish, they press it down cold. Because it’s colder, ya gotta push harder, but it makes the metal smoother and tougher in a way. Looks nice too, all shiny and smooth-like. So if someone’s makin’ a fancy shelf or somethin’ that folks are gonna see, they might pick cold rolled instead of hot rolled.

Uses of Rolled Sheet Metal

So, what do ya use all this rolled metal for anyway? Well, lemme tell ya, folks use it for all kinds of things:

- Building stuff – Hot rolled metal is perfect for big ol’ projects like buildings, bridges, and them big warehouse frames.

- Cars and trucks – A lotta car parts get made from hot rolled steel since it’s strong and gets the job done cheap.

- Furniture and appliances – For smoother, shinier stuff like cabinets or appliances, they might use cold rolled.

- Pipes and tubes – Rolled sheet metal gets used for makin’ pipes too, that go in homes, barns, and even them fancy skyscrapers.

Hot vs. Cold: Pros and Cons

Now, let me make this real simple. Hot rolled steel’s got its rough side, but it’s strong and cheaper – perfect when ya need somethin’ that’s big and solid. Cold rolled is all nice and polished, but it costs ya a little more, so it’s better for things that folks are gonna see up close.

How They Do It

Now, how do they roll it? Well, I’ll tell ya, it’s a big ol’ process. For hot rolled, they heat up that metal till it’s glowin’, then roll it through big rollers. For cold rolled, they use rollers too, but no heat. Cold rolled takes a bit longer since it’s a tougher process, but the metal comes out smoother.

Final Thoughts on Rolled Sheet Metal

Well, if ya need somethin’ solid, rolled sheet metal is the way to go. It can be thick or thin, hot rolled or cold rolled, and ya can use it for all kinds of things around the farm, the house, or even them big ol’ buildings. Just remember, hot rolled is for them big jobs and cold rolled is for when ya want it to look a bit fancy.

Tags: [rolled sheet metal, hot rolled steel, cold rolled steel, metal sheet uses, metal rolling process]