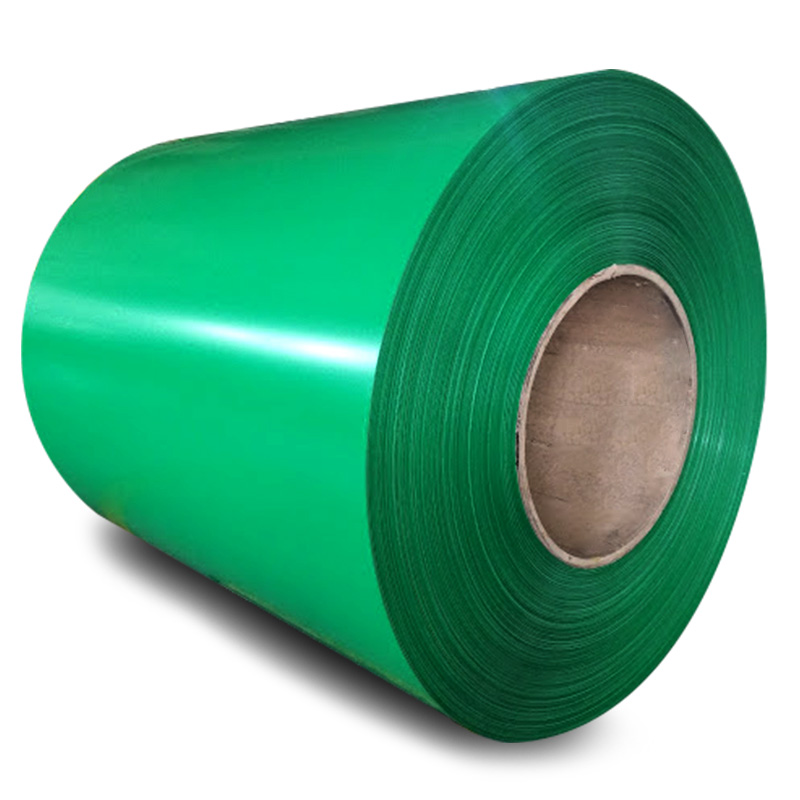

Hey there, metal enthusiasts! Let’s talk about something awesome – prime prepainted galvanized steel coils, or PPGI for short. If you’re in the construction, automotive, or appliance industries, chances are you’ve heard this term thrown around. But what exactly is it, and why is it so popular?

Well, imagine a steel coil, super strong and durable, coated with a beautiful, protective layer of paint. That’s basically it! PPGI is a game-changer because it gives you the best of both worlds – the strength of steel with the added bonus of a fantastic finish that looks great and lasts longer.

Why PPGI?

Think about it. Steel is a workhorse – strong, tough, and versatile. But it can be susceptible to rust, especially in harsh environments. Galvanizing, which is coating the steel with zinc, adds a layer of protection, slowing down the corrosion process. Now, imagine that same galvanized steel, coated with a high-quality, pre-painted finish. That’s where PPGI really shines.

Here’s why PPGI is the ultimate choice for many projects:

Corrosion Resistance: You know how rusty metal can be a real bummer? PPGI solves that problem. The zinc coating, combined with the paint, creates a powerful shield against the elements, keeping your project looking good for years.

Durability: Let’s face it, we all want things that last. PPGI is built to withstand the test of time. It’s resistant to scratches, dents, and other forms of wear and tear, making it perfect for both indoor and outdoor applications.

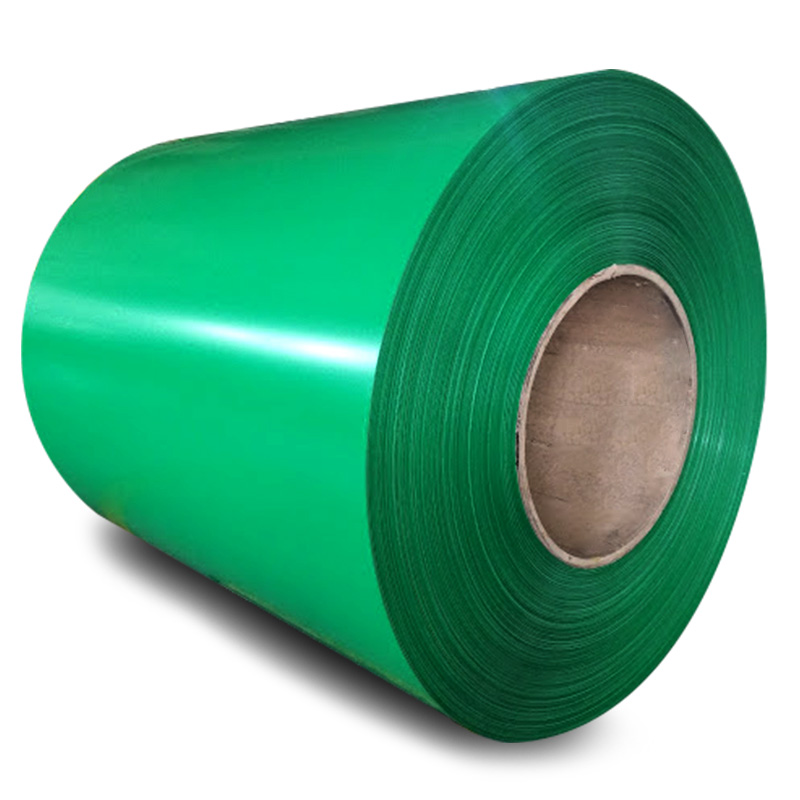

Versatility: Need a specific color or texture? No problem! PPGI comes in a wide range of colors, finishes, and thicknesses, allowing you to achieve your desired look and functionality.

Cost-Effective: PPGI might seem like a premium option, but it actually offers a cost-effective solution in the long run. Because it’s so durable and resistant to corrosion, it requires less maintenance and lasts longer than other materials, saving you money in the long run.

How is PPGI Made?

You might be wondering how they actually create this magical material. It’s actually a pretty cool process!

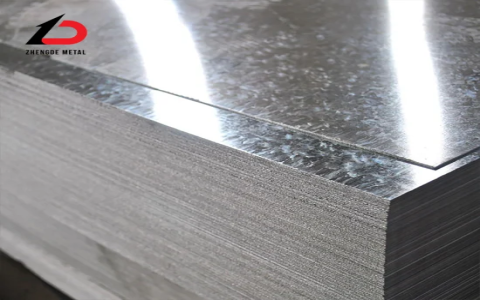

1. Start with a base: The journey begins with a steel coil, either hot-rolled or cold-rolled, depending on the desired properties.

2. Galvanizing time: The steel coil gets a bath in molten zinc, which creates a protective coating. This process is known as hot-dip galvanizing.

3. Painting perfection: After the galvanizing, the coil gets a fresh coat of paint. This is done in a continuous, automated process, ensuring a consistent and high-quality finish. The paint is typically applied to both sides of the coil at high speeds.

Where is PPGI Used?

PPGI is a real workhorse in the world of construction and manufacturing. You’ll find it used in a ton of applications:

Construction: From roofing and siding to exterior cladding and interior walls, PPGI is the go-to choice for durability and aesthetics.

Automotive: Think about those sleek car bodies and durable parts. PPGI is commonly used in automotive manufacturing to achieve both corrosion resistance and a beautiful finish.

Appliances: You’ll find PPGI used in everything from refrigerators and washing machines to ovens and microwaves. It’s perfect for appliances, as it can withstand the wear and tear of daily use.

Other Industries: PPGI is used in numerous other industries, such as agriculture, shipping containers, and even furniture.

Types of PPGI

There are a couple of common types of PPGI:

Prepainted Galvanized Steel Coil (PPGI): This is the most basic type, where the steel coil is galvanized and then painted.

Prepainted Galvalume Steel Coil (PPGL): This type uses a special aluminum-zinc alloy (Galvalume) as the coating instead of just zinc. Galvalume offers even greater corrosion resistance than traditional galvanized steel.

Choosing the Right PPGI for Your Project

With so many options available, how do you choose the right PPGI for your project? Here are a few factors to consider:

Corrosion Resistance: Will your project be exposed to harsh weather conditions? If so, you might want to opt for PPGL for extra protection.

Color and Finish: Do you have a specific color or finish in mind? PPGI is available in a wide range of options, so you can find the perfect match for your project.

Thickness: The thickness of the steel coil will affect its strength and durability. Consider the intended use of the PPGI and choose the appropriate thickness.

Here’s a table summarizing some key differences between PPGI and PPGL:

| Feature | PPGI | PPGL |

|---|---|---|

| Coating | Zinc | Aluminum-zinc alloy (Galvalume) |

| Corrosion Resistance | Good | Excellent |

| Cost | Generally lower | Generally higher |

A Word on Safety

Like with any material, always handle PPGI with care. Wear appropriate safety gear, including gloves and eye protection, when working with PPGI.

Get in Touch!

Have any questions about PPGI? Let me know in the comments below. I’d love to hear about your projects and how PPGI can help you achieve your goals.