“`browser

search(“rolled stainless steel process features”)mclick([8, 7, 14, 16, 6])

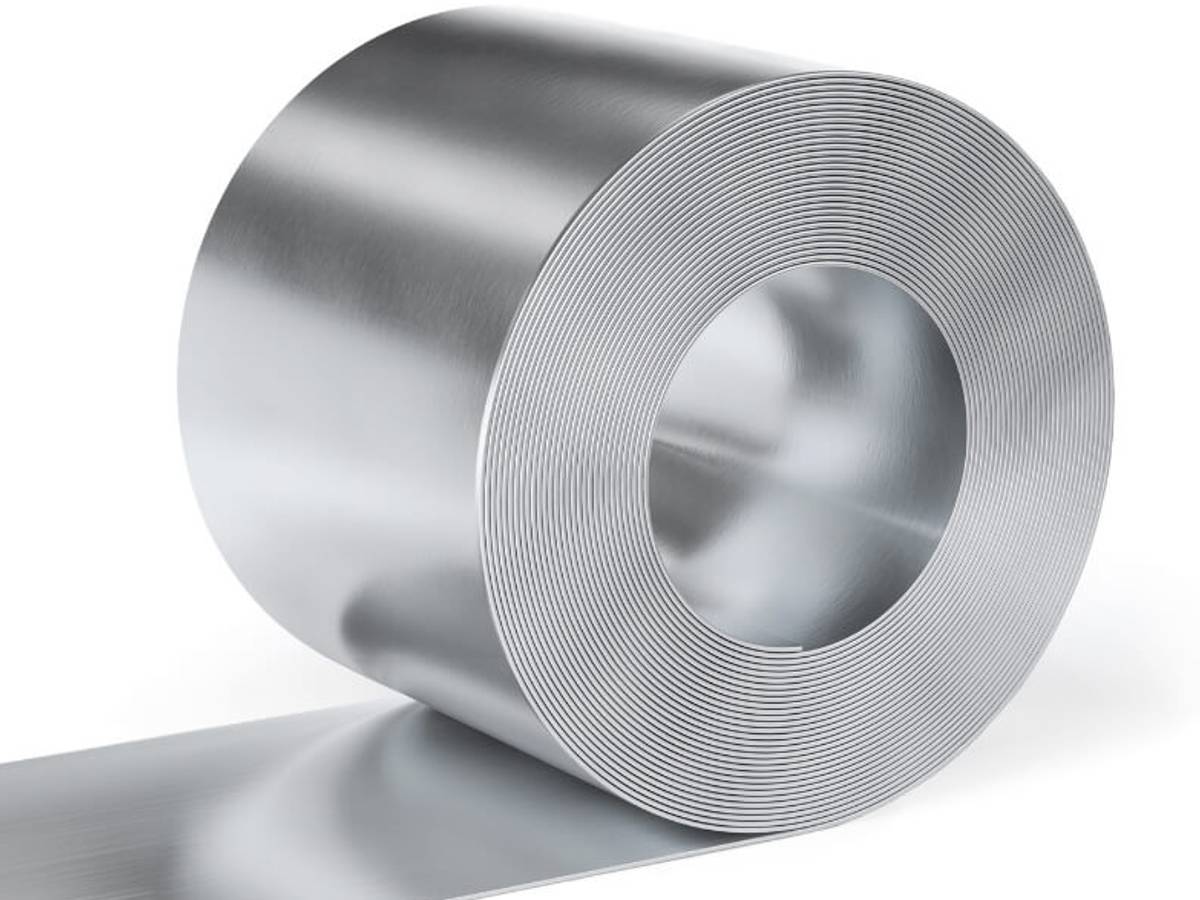

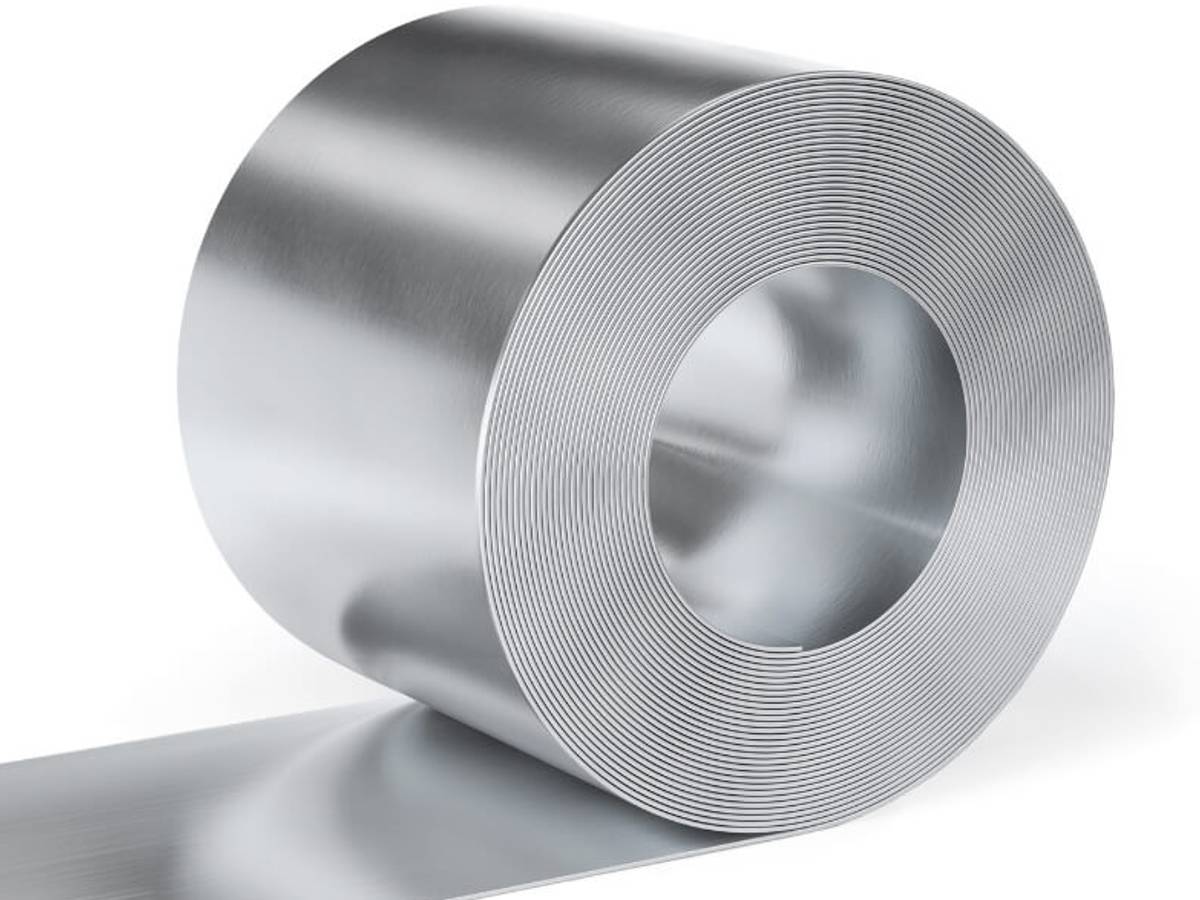

Oh, this rolled stainless steel, let me tell you, it’s somethin’ special. You know, folks like to use it ‘cause it’s strong, don’t rust much, and you can bend it and shape it just the way you need. Now, when they talk about “cold-rolled,” that’s when the steel gets rolled out without heatin’ it up too much. They just squeeze it real tight with some heavy rollers, and that makes the steel stronger. It’s like kneadin’ dough but a lot harder! This process helps the metal hold its shape better, and it’s real shiny too. Perfect if you want somethin’ strong but also nice lookin’ like for furniture or even them fancy machines.

But then there’s this other thing, “hot-rolled” stainless steel, and that’s done with heat. They make it when the steel’s still hot, so it’s easier to roll out. It’s good if you need somethin’ tough but don’t mind a bit of roughness. Hot-rolled steel ain’t as precise as cold-rolled, you might see it shrink a little here and there as it cools down. But it’s cheaper, and for big projects where looks don’t matter so much, like them tanker trucks or big ol’ buildings, hot-rolled works just fine.

Now, this stainless steel, why is it so good for rollin’? Well, it don’t rust easy and can take a beating. You’ll find it in all sorts of stuff, from kitchen sinks to parts in cars. There’s different kinds too! For example, there’s grade 201, which is cheaper but still strong, and grade 304, which is the go-to for most things ‘cause it resists rust and handles heat real good. And if you need somethin’ even stronger, there’s 316 steel – it’s got a bit more nickel in it, so it stands up to salty water and high temperatures without breakin’ down. You’d see this stuff in places like marine equipment or chemical plants.

What’s really neat about this rollin’ process, whether it’s cold or hot, is that it lets folks make long, straight pieces of steel without any breaks. That’s why they use it for things like office furniture, medical equipment, or even them solar panels. And let me tell you, once that stainless steel goes through them rollers, it’s not just stronger, but lighter too. That’s important if you’re makin’ stuff that needs to be tough but not too heavy, like them tanker trucks or appliances.

So, whether it’s cold-rolled for precision or hot-rolled for toughness, rolled stainless steel is everywhere you look. It’s used in industries like construction, appliances, and even the medical field. Strong, flexible, and resistant to rust – no wonder folks swear by it!

Tags:[rolled stainless steel, cold-rolled steel, hot-rolled steel, stainless steel grades, steel manufacturing]