You know, cold rolled steel, it’s got some real toughness to it. Now, folks always want strong stuff, don’t they? Well, this cold rolled steel, it’s done in a way that makes it harder, tougher – stronger than that hot rolled steel. That cold rolling, it’s like giving the steel a good pressin’ when it’s already cold, ya see. That’s what they call strain hardening, makin’ it extra stiff and strong, not like that hot stuff.

Why Cold Rolled Steel’s Got More Hardness

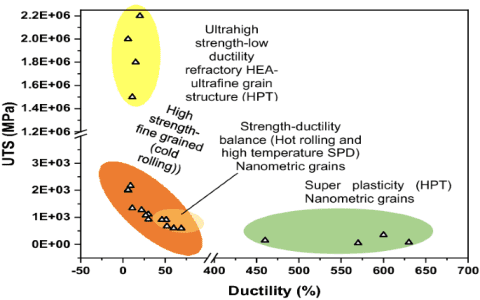

Now, with cold rolled steel, the hardness goes up, way up. When they roll that steel cold, it’s like they’re squeezin’ it tighter than hot rolled, and that makes the steel stronger. They say, for example, hot rolled steel might only have somethin’ like 235 MPa in yield strength – now, that’s fancy talk for how much it can take before it bends. But cold rolled? Oh, it goes above that, a good bit more. You’re lookin’ at close to 20% more strength with cold rolled. That’s why folks who need somethin’ sturdy, they’re choosin’ cold rolled steel. Strong and durable, that’s what it is.

The Process Makes It Harder

So, when they roll the steel cold, it ain’t just about makin’ it hard. There’s also the surface finish – that’s the look of it. Cold rolled steel has this smooth, nice finish to it. It’s all about that tight rollin’ process, keepin’ it all under control, none of that high heat business. Cold steel gets stronger by rollin’ it out just so, almost like kneadin’ dough, but without the heat. Now, that heat, when you take it out, you keep more hardness and less mess.

What’s the Real Difference Between Cold and Hot Rolled Steel?

- Cold rolled steel – that’s rolled at room temperature. Stronger, harder, and a real nice finish on the outside.

- Hot rolled steel – that’s done hot. Comes out a bit softer, and the finish ain’t as smooth.

Now, some folks might wonder why you’d even want hot rolled steel when cold rolled is so much tougher. Well, that hot rolled steel, it’s easier to shape and cheaper to make, so if you don’t need all that hardness, hot rolled might still do the job. But if it’s strength you’re after, cold rolled steel’s where it’s at.

Uses of Cold Rolled Steel Because of Its Hardness

Because cold rolled steel’s so strong, it’s used for all sorts of things. It’s real popular in things like car parts, appliances, furniture – anything where you want something that won’t just break or wear down too quick. That hardness makes it last. It can hold up to all sorts of stress without givin’ out, which is just what you want in materials like that. Tough as nails, and lasts a long time.

All that hardness comes from how they roll it. It’s that strain hardening, like I mentioned, squeezin’ it cold to get it tough. You don’t get that same strength if you heat it up, which is why they do it cold. It’s the go-to choice when strength and durability are what’s needed.

Conclusion

So, when it comes down to it, cold rolled steel – it’s got the strength, the hardness, and the look. It’s that cold rollin’ process, squeezin’ it without heat, that makes it special. It’s all about makin’ steel tougher, harder, and better for long-lasting use. Next time you see somethin’ made out of steel and it’s holdin’ up just fine, there’s a good chance it might be cold rolled. Strong stuff, this cold rolled steel, and it ain’t goin’ anywhere.

Tags:[cold rolled steel, hardness, yield strength, strain hardening, steel durability, cold vs hot rolled steel]