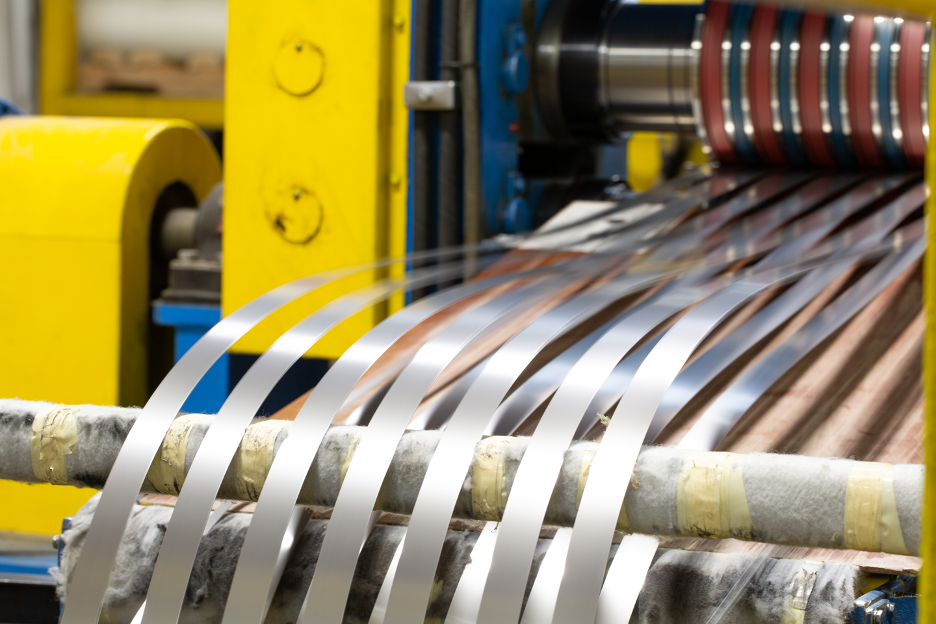

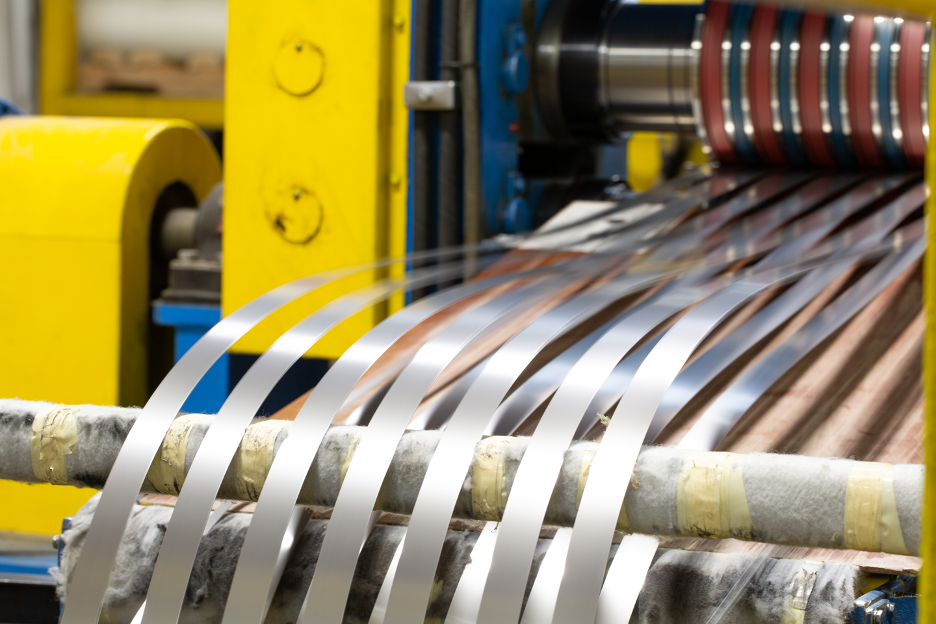

You see, a coil slitter is a big ol’ machine for cutting wide coils into skinny strips. Folks use it for all sorts of things, especially when they start with a fat coil of metal like steel or aluminum. This machine, well, it’s quite smart—it cuts that wide sheet into smaller pieces to make it fit for different uses. This process is real handy in factories where they need metal in just the right size for different jobs.

Now, let me tell you how it works. They start by putting a big ol’ master coil—that’s just a big roll of metal—onto the slitter machine. First off, they unwind it, kinda like you’d unroll a rug, you know? Then, they feed that metal through what they call a pinch-roll leveler. This step smooths the metal out a bit and gets it straightened up before it hits the cutter. This leveler makes sure the metal don’t get all twisted or bumpy, which would mess up the slitting process for sure.

Then comes the real slicing part! Once it’s all lined up, that coil slitter machine uses a bunch of sharp rotary knives, cutting that metal into narrower coils, like cutting a big ol’ pie into slices. Each slice, they call it a mult. These mults, well, they’re just smaller coils that come in whatever width a customer might want. And this ain’t no regular knife job; those knives spin ‘round and slice that metal slick as a whistle.

After all that cutting, the slitter machine does a bit more magic. It coils each of those narrow strips back up, so they’re easy to move and store. These smaller coils are handy since they’re the right size for all kinds of industries. Folks use ‘em in automobiles for trim, in electronics for gadgets, in HVAC systems for ducts, and even in household appliances and medical stuff. There’s a lot of places these narrow coils go once they’re cut to size, let me tell ya.

Sometimes, folks need these coils real specific in width or weight, so they can get ‘em customized. That way, they don’t waste a lick of metal and can pack it all just right for whatever job they’re doing. After the cutting and coiling, the machine stacks ‘em up all neat, ready to ship out.

So, to sum it up, a coil slitter does three big things:

- Decoiling: Takes that big coil and unwinds it.

- Slitting: Slices it into skinnier strips.

- Recoiling: Rolls those skinny strips back up nice and neat.

That’s pretty much the whole process of coil slitting in a nutshell. It might sound simple, but these machines are powerful and precise, making sure each cut is just right. They work fast, too, making all these strips real quick. And once they’re done, those mults are ready to go anywhere they’re needed, cut just the way each industry likes.

In the end, this coil slitter machine saves folks a ton of trouble, cuts down on waste, and gets the job done with speed and precision. And that’s why you see these things used all over where metal is needed in different shapes and sizes. Makes life a whole lot easier for folks in industries that need to work with metal every day, that’s for sure!

Tags:[coil slitter, metal processing, slitting machine, coil slitting process, metal industry, steel, aluminum, manufacturing]