Now, when we talk about drawing steel, we’re talkin’ about makin’ steel that’s a bit softer and more flexible, just enough to let it be shaped and bent around without breakin’. This kind of steel’s called drawing steel ’cause it’s made to be pulled and stretched, not in some fancy high-tech way, but by simple means—just pullin’ it through dies and stretchin’ it out. It’s like makin’ dough thin for dumplings; you work it until it’s the right thickness and shape.

See, drawing steel ain’t got much carbon in it, not more than about 0.05 percent, give or take. Less carbon means it’s easier to bend, but it still keeps its shape well enough for what it’s used for. Factories like this steel when they gotta make things that need to be drawn out or made thin without snappin’ or crackin’. Think about cars or appliances—they got parts that need to bend a bit but also be strong enough to hold together, right? Well, that’s what drawing steel is made for.

Types of Drawing

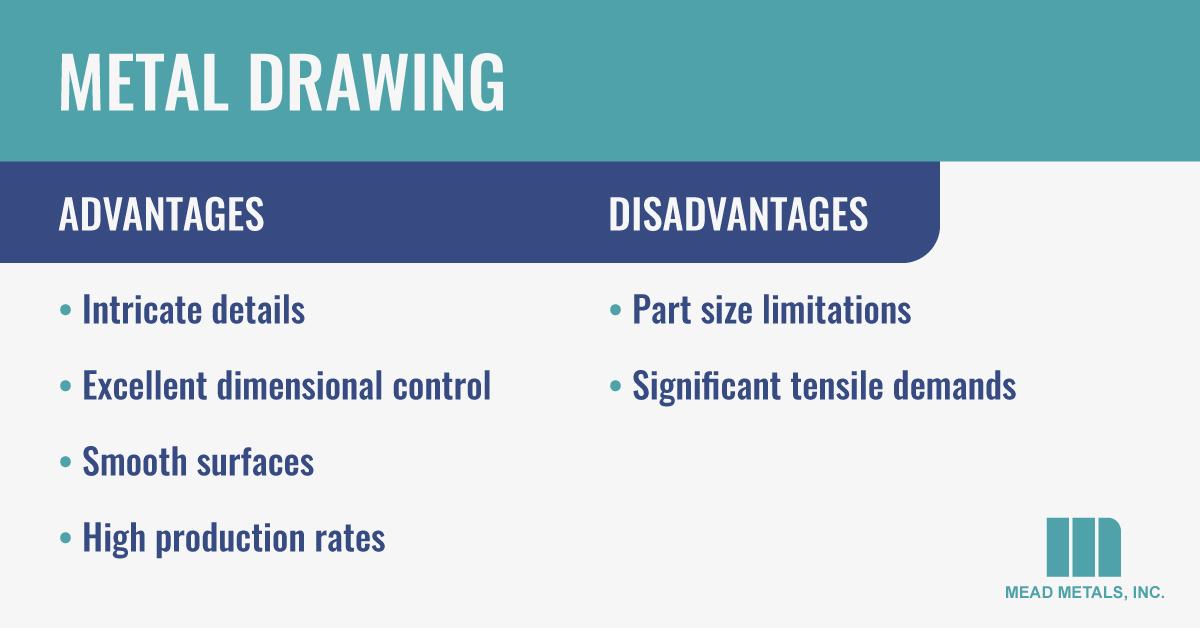

Now, there’s two main kinds of drawing we see when it comes to steel:

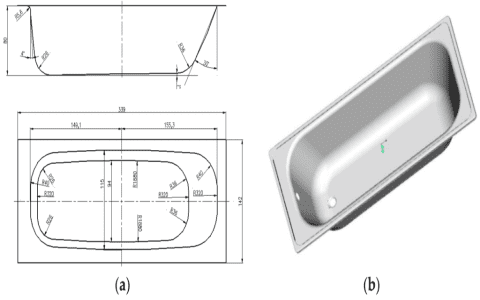

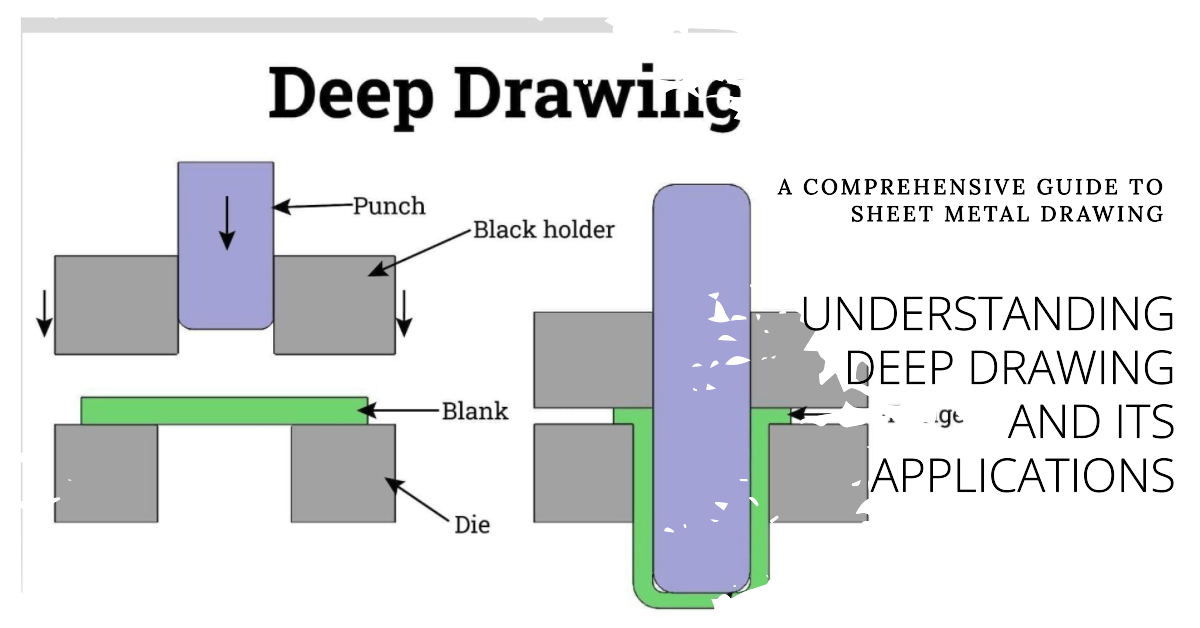

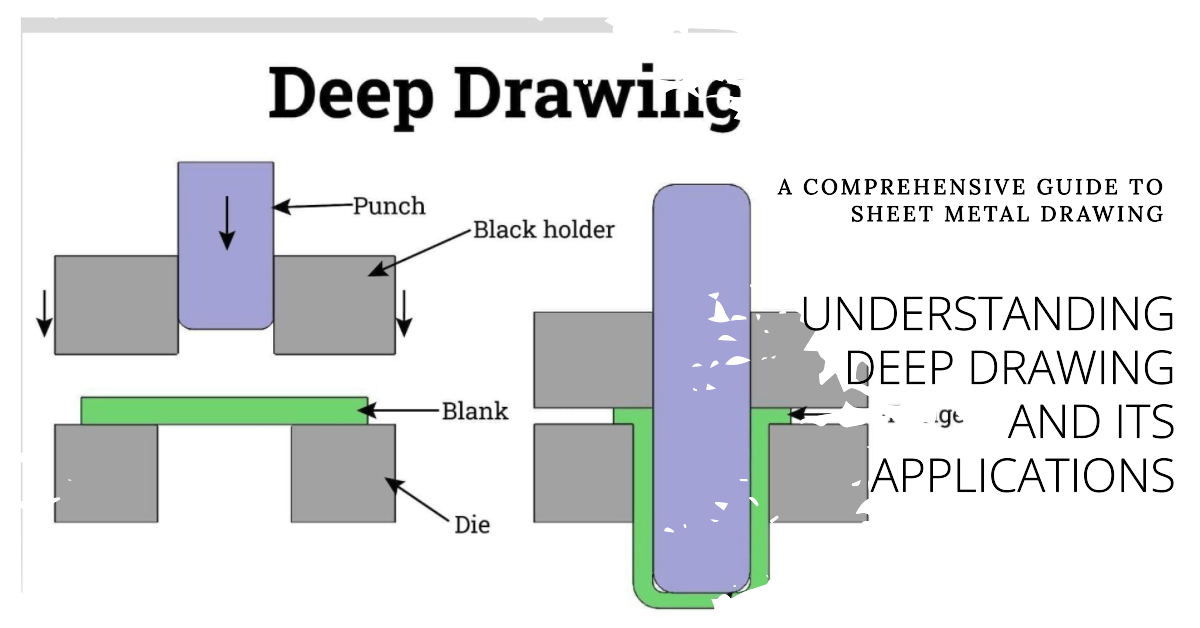

- Sheet Metal Drawing – This is when you take a flat sheet of steel and shape it using a die. Just picture this die like a mold that forces the metal into the shape it’s gotta take, like how you’d press dough into a mold for cookies.

- Wire and Bar Drawing – This here’s about stretchin’ the metal along its length, makin’ it longer and thinner as you go. If you’ve ever stretched out a bit of chewed gum, it’s kinda like that, but much stronger and more controlled.

Process of Drawing Steel

When you’re makin’ drawing steel, they start with cold-drawing. Now, cold-drawing means pullin’ that steel through a die at room temperature. Don’t go thinkin’ this is like makin’ bread dough where heat helps, no. Here, the steel needs to stay cool ’cause if it gets too hot, it won’t hold its shape well. And we don’t want that, now do we?

Unlike cold-rolled steel, which goes through rollers, cold-drawn steel gets pulled and squeezed through a die. This squeezin’ makes it thinner and longer, just like that gum I mentioned, except they’ve got the right tools to keep everything smooth and even. That way, the steel comes out lookin’ neat and tidy, just the right size and thickness for the job it’s meant to do.

Materials That Can Be Drawn

Steel ain’t the only material that folks use this drawin’ method on, no sir. They also do it with copper, aluminum, even plastic and glass. In fact, when they’re makin’ glass fibers for things like Internet cables, they use a similar pullin’ process to stretch that glass nice and thin. Plastic, too, when it’s used to make fibers, gets drawn out and stretched, though not in quite the same way as metals. But steel, especially drawing steel, it’s real special ’cause it can hold its shape better than many other materials. It’s tougher, lasts longer, and doesn’t snap under pressure as easily.

Benefits of Using Drawing Steel

One big reason why they go for drawing steel is ’cause it’s soft enough to shape but strong enough to last. Factories makin’ car parts, appliances, and even tools—they like this kind of steel ’cause they can bend and shape it without worryin’ about cracks or breaks. And since it’s got just a little bit of carbon, it’s also less likely to rust up quick. This steel’s reliable for makin’ all sorts of everyday things, things we use without even thinkin’ much about where they come from.

So, you see, when it comes to makin’ products that gotta be both tough and bendable, drawing steel fits the bill just fine. It’s a humble kinda material, but it does a big job. From car doors to refrigerator parts, this steel’s there in the background, doin’ what it’s meant to do. And that’s why folks in the steel business like it so much.

Wrapping it Up

In the end, drawing steel might not be somethin’ fancy, but it’s sure enough useful. It gets the job done by bein’ soft enough to shape and strong enough to keep things in place. So next time you see somethin’ made of steel that’s got a bit of a bend or curve to it, just think: that might just be good ol’ drawing steel, stretched and pulled to be just right for whatever it’s needed for. Simple, straightforward, and always reliable—just like it oughta be.

Tags:[drawing steel, steel manufacturing, sheet metal drawing, cold-drawn steel, wire and bar drawing, metalworking]