Steel draw, oh, well, lemme tell ya, it’s quite somethin’. Basically, it’s a way of stretchin’ and pullin’ steel, makin’ it long and thin, all in the shape ya need. Imagine just takin’ a piece o’ steel and givin’ it a good ol’ tug! Course, it ain’t that simple. Folks gotta use big ol’ machines and all sorts o’ tools for this. But at the end, what ya get is somethin’ that’s tough, strong, and fits just what ya need it for.

What Exactly Is Steel Drawing?

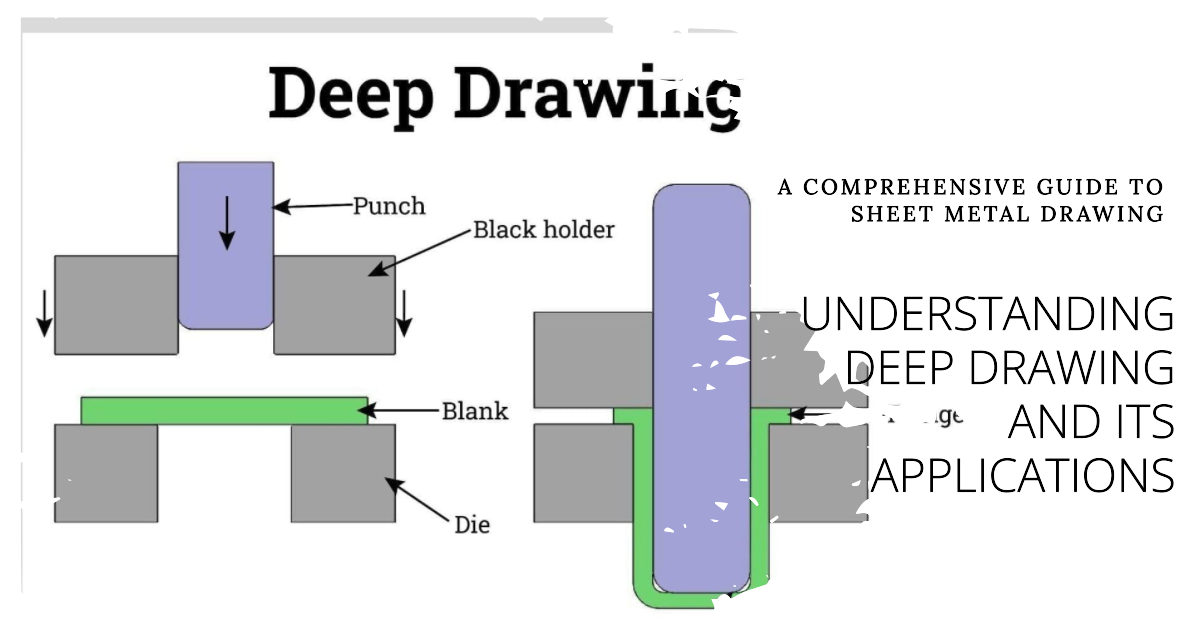

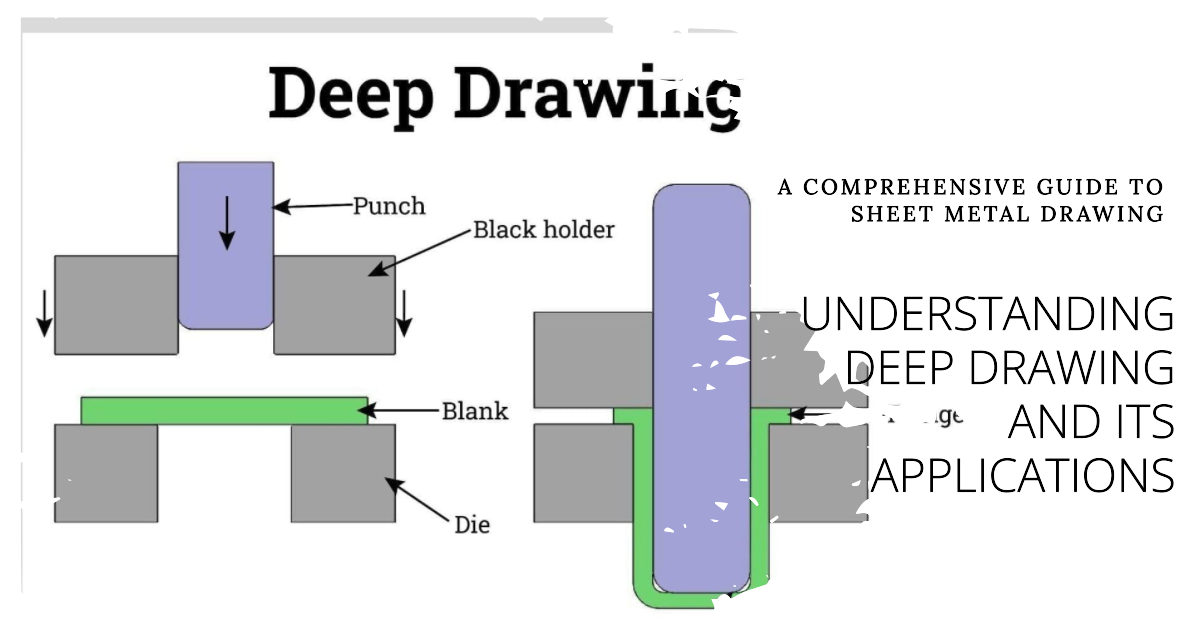

So, steel drawin’, ya see, it’s this process where ya pull steel so hard that it gets thinner and stretches out. There’s a couple types of drawin’ they do. There’s sheet metal drawing, where ya start with a flat sheet, and they press it down with a die till it’s shaped all nice. Then there’s wire, bar, and tube drawing, where ya take a chunk like a bar or wire and stretch it real good till it’s just right.

This whole drawin’ thing don’t just work with steel neither, nah! They do it with copper, aluminum, and even plastic and glass. But steel’s real good for it ‘cause it’s got that strength, see? Doesn’t tear easy and keeps its shape. That’s why they use steel drawin’ a whole lot in all sorts o’ things, from car parts to pipes.

How Steel Drawin’ Works

Now, ya might think, “Well, why not just roll it out or hammer it?” That’s where drawin’ shines. When ya pull steel, it flows. The steel stretches and moves along, makin’ it even and smooth. They use somethin’ called a die, a tool that’s got the shape they want. Steel’s pulled right through it, and like magic – out comes this fine piece of metal, strong and thin.

For folks that know the difference, this process is also real different from cold rolling. Now, with cold-drawn steel, they do it at room temperature, so ya don’t got all that heat like in other steelwork. This cold drawin’ gives ya an extra smooth and tough piece o’ steel, perfect for when ya need somethin’ real precise.

Why Folks Use Steel Drawing

Why, ya ask? Well, there’s plenty o’ reasons. For one, drawin’ gives ya steel with fine shape and size that ya just can’t get easy with other methods. It’s used in makin’ real precise things, like the small parts in cars and machines, where every little bit matters. Steel’s tough, so drawin’ makes it keep that strength even in a thin form.

- Uniformity: Steel drawin’ keeps the thickness all nice and even.

- Smooth Surface: Cold-drawn steel, especially, comes out all smooth and nice lookin’.

- Strength: Drawn steel keeps tough, which is real handy for all sorts o’ parts.

Drawin’ steel’s also a fine way to save material. Instead o’ hackin’ off extra bits, ya just shape it right the first time. Less waste, less fuss, and ya end up with just the right piece for the job.

Where Ya Might See Drawn Steel Around

Steel drawin’ shows up in all sorts o’ places, from car parts to construction beams and even some bits in machinery. Now, most folks might not even notice, but there’s drawn steel in plenty o’ things around ’em! Those little rods in buildings, or even some plumbing parts – a lot of ’em are made with drawn steel to make sure they stay strong but don’t weigh too much.

The Difference Between Steel Drawing and Other Methods

There’s all kinds o’ ways to shape steel. Rollin’, extrudin’, stampin’ – but each has its own job. Drawin’ steel, it’s special ‘cause it lets folks make real precise parts, often used for things that need that extra detail. Plus, drawn steel’s got that good mix of strength and smoothness. That’s why it’s used in makin’ all those small and complicated parts that need to hold together without breakin’.

In Short

Steel drawin’, it’s all about takin’ that hard metal and shapin’ it till it’s just what ya need. They pull it, stretch it, and make it fit all nice for any job ya got. Whether it’s for keepin’ cars runnin’ or makin’ pipes tough, drawn steel does the trick every time. So next time ya see a bit o’ steel, just think – maybe it’s been pulled through one o’ those dies, stretched till it was just right for its job!

Tags:[steel drawing, steel drawing process, cold-drawn steel, sheet metal drawing, wire drawing, manufacturing steel]