Introduction to Color Coated Aluminum Coils: Benefits, Applications, and Features

Overview

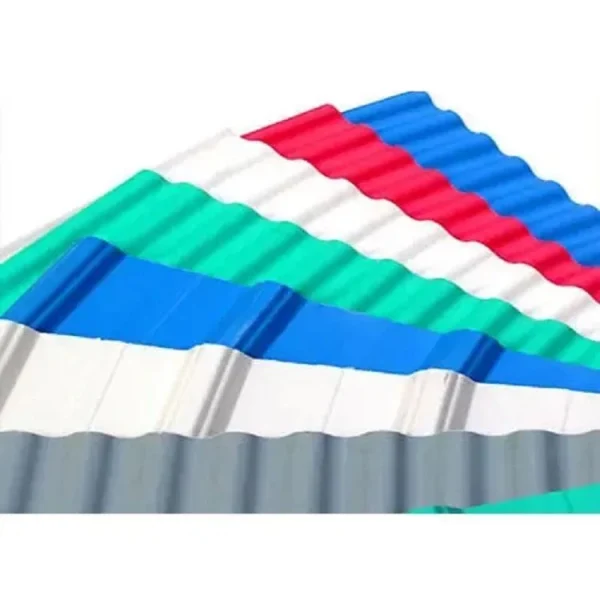

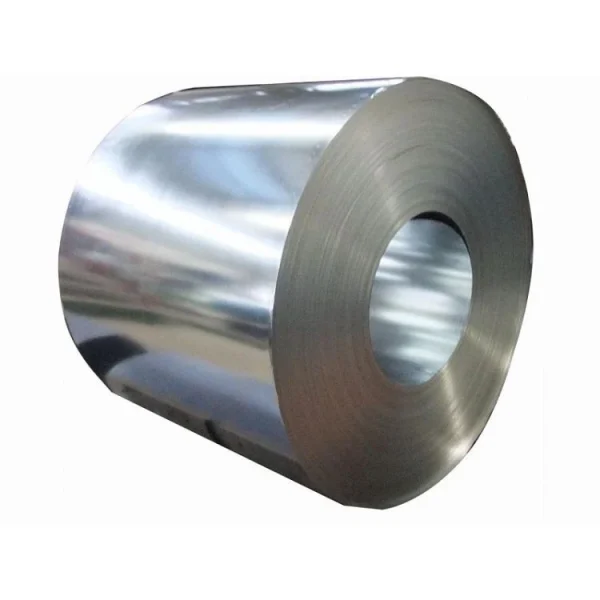

Color coated aluminum coils are a versatile material widely used in various industries due to their strength, durability, aesthetic appeal, and resistance to corrosion. These coils are aluminum sheets coated with a layer of paint or other coatings, available in a wide range of colors and finishes. The color coating not only enhances the visual appeal but also improves the material’s resistance to environmental factors. In this article, we will explore the benefits, features, and applications of color-coated aluminum coils in different sectors.

What is a Color Coated Aluminum Coil?

Color-coated aluminum coils are aluminum sheets that have been coated with a layer of paint, polyester, or PVDF (polyvinylidene fluoride). The coating is applied using advanced processes such as coil coating, where the aluminum coil is passed through a series of rollers that apply the desired paint or coating. This process results in a uniform, high-quality finish that is durable, attractive, and suitable for a wide range of applications. The coils come in various colors and can be customized with different textures, including matte, glossy, or metallic finishes.

Benefits of Color Coated Aluminum Coils

- Aesthetic Appeal

One of the primary reasons for using color-coated aluminum coils is their aesthetic versatility. These coils are available in a broad spectrum of colors and finishes, making them ideal for both functional and decorative applications. Whether used for building facades, signage, or home appliances, color-coated aluminum adds a modern and vibrant look to any project. - Durability and Longevity

Color-coated aluminum coils are known for their durability. The coating protects the aluminum from environmental factors like UV rays, rain, and pollution, extending the material’s lifespan. The paint or coating also resists fading, scratching, and chipping, ensuring that the aluminum maintains its appearance over time. With proper care, color-coated aluminum coils can last for decades without significant degradation. - Corrosion Resistance

Aluminum naturally offers excellent corrosion resistance, and the additional color coating further enhances this property. The coating forms a protective layer that shields the aluminum from rust, moisture, and chemicals, making it ideal for applications in harsh environments, such as coastal areas or regions with high humidity. - Low Maintenance

Color-coated aluminum coils require minimal maintenance. The smooth, durable surface resists dirt, grime, and stains, making cleaning straightforward. In comparison to other materials, color-coated aluminum does not need frequent repainting or refinishing, reducing the long-term maintenance costs. - Energy Efficiency

The color coating on aluminum coils can improve the energy efficiency of buildings. Lighter-colored coatings reflect heat, reducing the need for air conditioning and keeping buildings cooler in hot climates. This property helps lower energy consumption and makes color-coated aluminum a sustainable choice for building materials. - Environmental Friendliness

Aluminum is a highly recyclable material, and color-coated aluminum coils are no exception. The production of these coils involves minimal waste, and the material can be recycled at the end of its lifespan, reducing environmental impact. Additionally, the energy-efficient properties of color-coated aluminum contribute to sustainable building practices.

Applications of Color Coated Aluminum Coils

- Architectural and Building Applications

Color-coated aluminum coils are commonly used for exterior and interior applications in the construction industry. They are widely used for cladding, facades, roofing, and wall panels. Their weather-resistant properties make them ideal for outdoor applications, while their aesthetic flexibility allows for creative and modern designs in commercial and residential buildings. - Signage and Advertising

The vibrant colors and smooth finish of color-coated aluminum coils make them a popular choice for creating eye-catching signage and advertising displays. They are often used in the production of billboards, store signage, and vehicle wraps, offering a long-lasting, visually appealing solution for branding and marketing. - Automotive Industry

Color-coated aluminum coils are also used in the automotive industry for components like body panels, trim, and decorative parts. The lightweight nature of aluminum helps improve fuel efficiency, while the color coating provides an attractive finish that resists wear and tear from environmental exposure. - Home Appliances

Color-coated aluminum is used in the production of home appliances such as refrigerators, washing machines, air conditioners, and ovens. The coating adds aesthetic value while providing additional protection from scratches, corrosion, and fading, extending the life of the appliances. - Consumer Electronics

In consumer electronics, color-coated aluminum coils are used for devices such as laptops, smartphones, and tablets. The aluminum provides a strong yet lightweight frame, while the color coating adds a premium look and enhances the device’s resistance to wear and environmental damage. - Packaging

Color-coated aluminum coils are commonly used in the packaging industry for products that require an attractive finish and protection from external factors. Examples include packaging for food, beverages, cosmetics, and pharmaceuticals, where the coating ensures product safety and enhances the consumer experience.

Types of Coatings Used for Color Coated Aluminum Coils

- Polyester Coatings

Polyester-coated aluminum coils are widely used for general applications due to their affordability and good resistance to UV radiation. They are commonly used for building materials, signage, and home appliances. - PVDF (Polyvinylidene Fluoride) Coatings

PVDF coatings are highly durable and offer superior resistance to UV rays, chemicals, and weathering. They are often used in high-end architectural applications, including cladding, facades, and roofing, where long-lasting performance is required. - Polyurethane Coatings

Polyurethane coatings provide excellent scratch resistance and are used in applications that require a high-quality, durable finish, such as in automotive parts and high-end consumer goods.