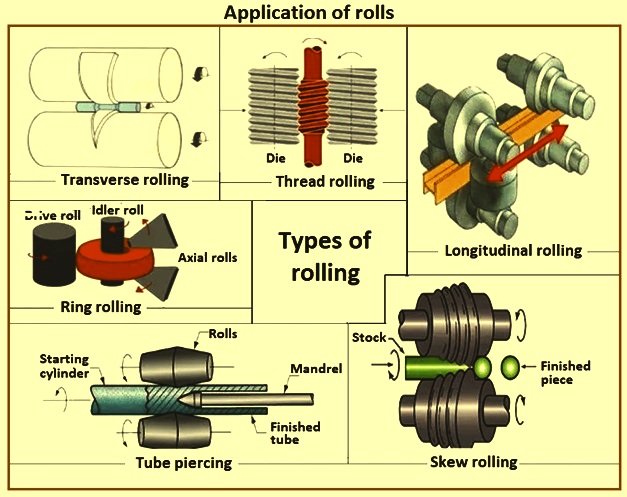

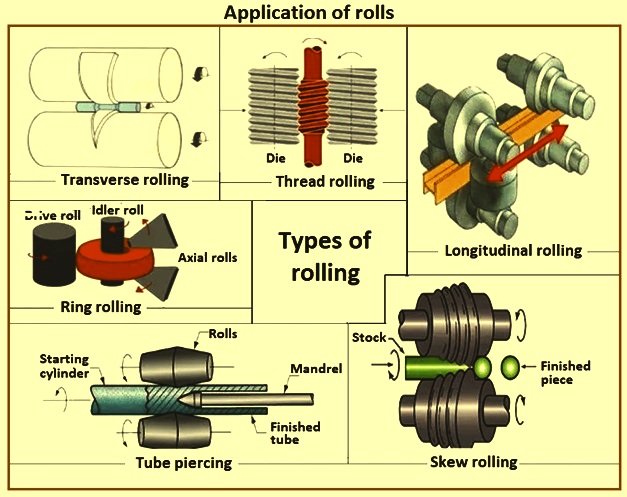

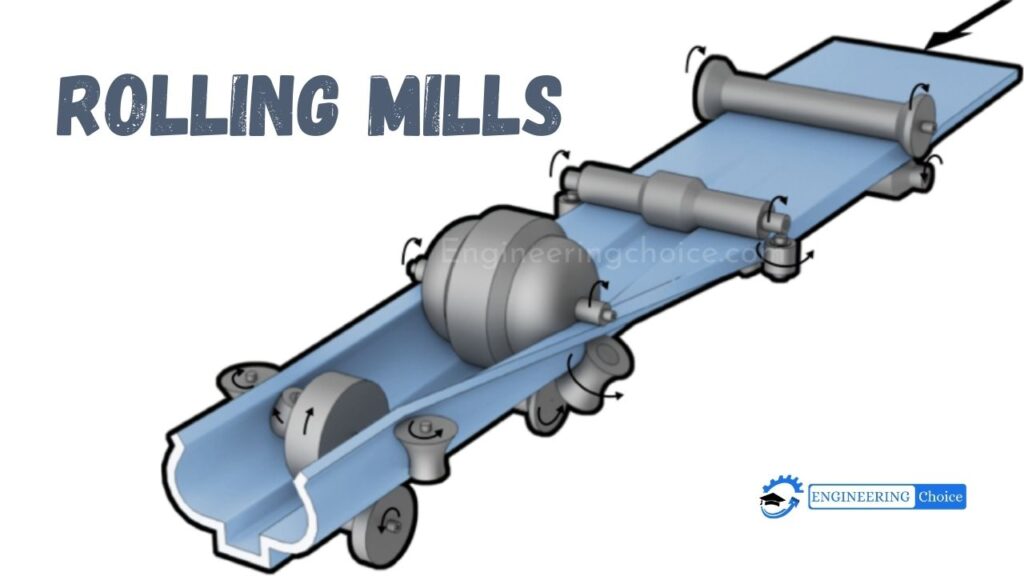

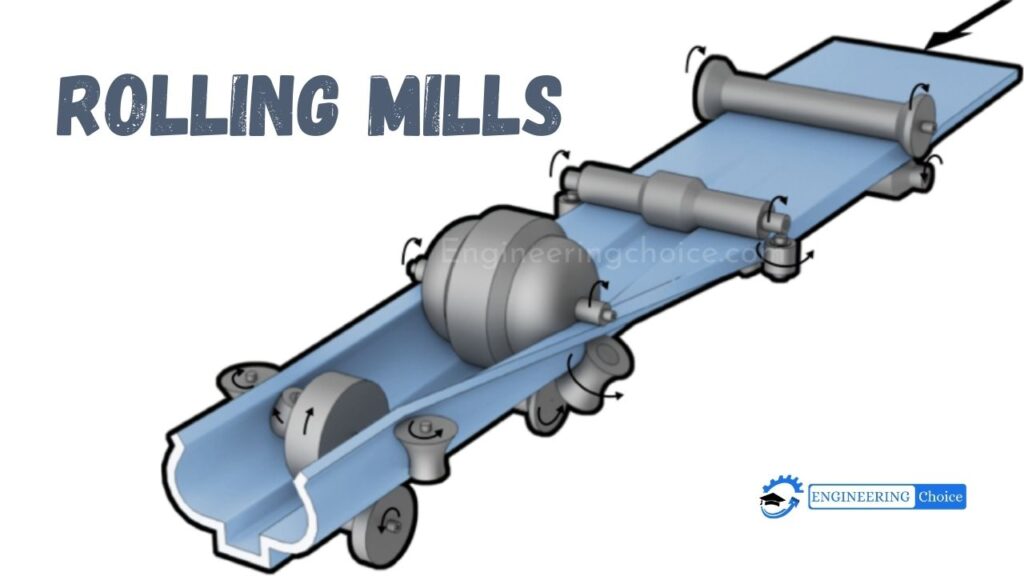

Well, let me tell ya, these cold rolling mill rolls are somethin’ special, ya know? Now, what’s a cold rolling mill, you ask? It’s kinda like one o’ them machines that takes a big ol’ piece of metal, like steel, and squeezes it down, makes it thinner and smoother. That steel goes through a buncha rolls, rollin’ over and over, till it’s flat as can be.

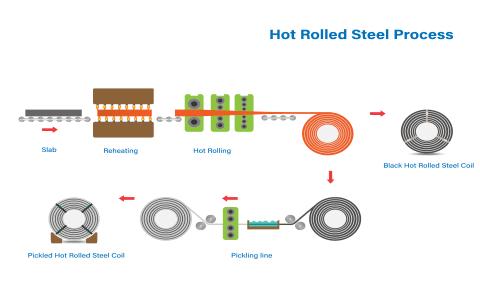

Now, lemme break it down a bit more. Cold rolling, it’s real different from hot rolling. Ya see, hot rolling gets done when the steel’s all heated up, soft as bread dough. But cold rolling? Nah, this stuff happens at lower temps – like from around 60°C to maybe 180°C. So, the steel’s already cooled off quite a bit after hot rollin’, and then they run it through these cold rolling mill rolls to get it just right. It ain’t easy, but that’s how ya get them thin steel sheets, ya know?

These cold rolling mill rolls, they’re real tough. Made to last, ya could say, ’cause they gotta deal with steel movin’ fast – like 40 meters a second or so! That’s fast, alright. They put a lil’ kerosene oil on it, so it don’t get too hot or sticky. The oil helps it move nice and smooth. Keeps everything runnin’ without too much fuss.

Benefits of Cold Rolling Mill Rolls

- Stronger Steel: Cold rolling makes that steel tougher than hot rolling. Gives it that extra strength, ya know?

- Smoother Surface: With all that rollin’, ya end up with a real nice, smooth finish. Makes it look like somethin’ special.

- Thin and Precise: Ya can make it real thin, just how ya want it, anywhere from around 6mm down to as tiny as 0.06mm. That’s some fine work there!

Alright, so ya got these cold rolling mills, and they work mainly on sheets and coils o’ steel. That’s what ya see in stuff like fridges, cars, and other gadgets. Now, some folks talk about the annealin’ process too – that’s when they heat it up just right to make it easier to work with. They got fancy ways of doin’ it too, like “Cold Spot Anneal” and a buncha others. But that gets a lil’ technical for most, I reckon.

There’s a few types of cold rolling mills too. Ya got mills that work best on softer metals and others that do a bang-up job on all kinds of widths. They keep up with demand, doin’ cold rollin’ all day, makin’ that steel tough and shiny. This kinda mill’s also big – takes up a fair bit o’ space and costs a pretty penny too. But it’s worth it, ‘cause these mills handle most o’ the steel ya see every day. Yep, almost 90% of steel goes through these mills before it turns into somethin’ useful.

One thing’s for sure: without these cold rolling mill rolls, the steel wouldn’t be as strong or as nice lookin’. So, next time ya see a car or a fridge, just remember, somewhere there’s a big ol’ machine that helped make it look that good and work that well.

So, there ya have it – a lil’ rundown on these cold rolling mills and what they do. It’s simple stuff but mighty important if ya need steel that’s strong and smooth. And if ya ever wondered how they make metal sheets so thin and tough, well, now ya know!

Tags:[cold rolling mill, cold rolling mill rolls, steel processing, cold rolling benefits, cold rolled steel]