Oh, let me tell ya ’bout this here thing called cold-drawn. Sounds all fancy, but really, it’s just a way of makin’ metal, specially steel, tougher and smoother. Ya see, when folks talk ’bout cold-drawn steel, they’re talkin’ about steel that’s shaped at room temperature instead of heatin’ it all up. Real useful for them projects where ya want things to look nice and be strong.

So, what’s the big fuss ’bout cold-drawn, ya might wonder? Well, here’s the thing:

- Stronger and Tougher: Cold-drawn steel don’t mess around. It’s tough as nails. By squeezin’ and pullin’ that steel through these special molds at cold temps, it gets harder, kinda like how a rock feels after sittin’ in the sun all day—solid, y’know?

- Smoother Finish: This steel here? Smooth as a baby’s cheek! That cold-drawin’ helps take away all them rough spots, so it don’t need much polishin’. Perfect for things that need to look all clean and fancy, like in buildin’ stuff or machines.

- Better Shape: Cold-drawn steel stays the way ya want it. Not like hot-rolled steel that can end up lookin’ all bumpy and outta shape when it cools down.

Now, ya might think, “Why go to all that trouble with cold-drawin’?” Well, it’s simple. Cold-drawn steel is mighty good for makin’ small parts, like them gears or bolts folks use in engines, machines, and even furniture. ‘Cause it’s so precise, ya get these parts that fit right where ya need ’em, like pieces of a puzzle. If ya tried usin’ hot-rolled steel, you’d be fiddlin’ around tryin’ to make it fit, which ain’t no good.

How’s it Done, Then?

Well, cold-drawin’ starts with hot-rolled steel. Yeah, sounds funny, don’t it? But first, they gotta get that steel all soft and easy to handle. Once it’s cooled down, it gets put through a mold, kinda like squeezin’ dough through a cookie cutter. They pull it and stretch it till it’s the shape and size they’re after. And it ain’t easy—takes special machines and tools. By the end, ya got yourself cold-drawn steel that’s stronger and smoother than the plain stuff.

Where Folks Use Cold-Drawn Steel

Lots of places, really. Like I said, anythin’ that needs to be strong and smooth. Ya see it in car parts, like them axles and rods, or in little tools and even in furniture bits. Even for them tiny parts in big machines, they’ll be usin’ cold-drawn steel. It’s just too handy not to use, ya know?

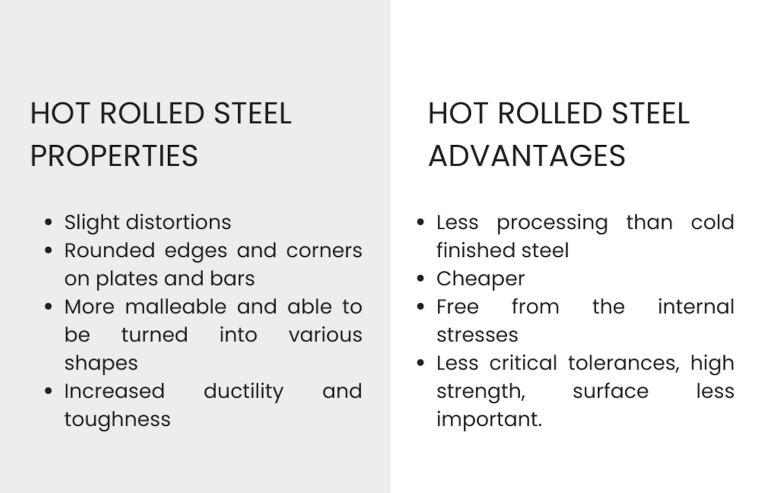

Hot-Rolled vs. Cold-Drawn

Now, if you’re wonderin’ what’s the big difference between cold-drawn steel and hot-rolled steel, well, let me tell ya plain: hot-rolled steel is like bakin’ a cake. It gets all puffy and changes shape as it cools. Cold-drawn steel, though, keeps its shape, kinda like that stiff dough that don’t rise much. So, ya use hot-rolled steel when ya don’t care too much ’bout looks or exact size, like makin’ big ol’ sheets for buildings. But when ya need it nice and precise, ya go for cold-drawn.

Costs and Other Bits

Now, this cold-drawn stuff can cost a bit more than hot-rolled steel. Why? Well, it’s all that extra work they do, draggin’ it through molds and all. But let me tell ya, it’s worth every penny if ya need your steel to be just right. Plus, since it’s stronger, sometimes ya end up usin’ less of it, so in the end, it can save ya money.

So there ya go. Cold-drawn steel ain’t just some fancy talk. It’s useful, tough as anything, and pretty too. When ya need somethin’ sturdy and smooth, ya can bet cold-drawn steel’s the one ya want!

Tags:[Cold-Drawn Steel, Cold-Drawing Process, Steel Manufacturing, Hot vs. Cold Steel]