Alright, let’s talk about this blanking process in sheet metal thing. Don’t you go thinkin’ this is gonna be some fancy-pants talk, I’m gonna tell ya like it is, plain and simple.

So, you got this big ol’ sheet of metal, right? Like, the kind they use to make cars or pots and pans, that kinda stuff. And you need a piece out of it, a specific shape, not just any old cut. That’s where blanking comes in. It’s like cuttin’ cookies, but with metal, and a whole lot tougher.

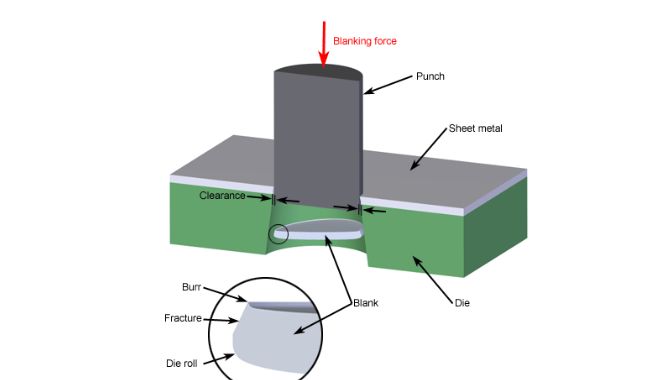

Think of it like this: you got your dough all rolled out, that’s your sheet metal. Then you got your cookie cutter, that’s your die. And when you slam that cutter down, bam! You got your cookie, or in this case, your blank. That’s the piece you wanted. The rest of the metal, the part with the hole, that’s just scrap, we don’t need that no more.

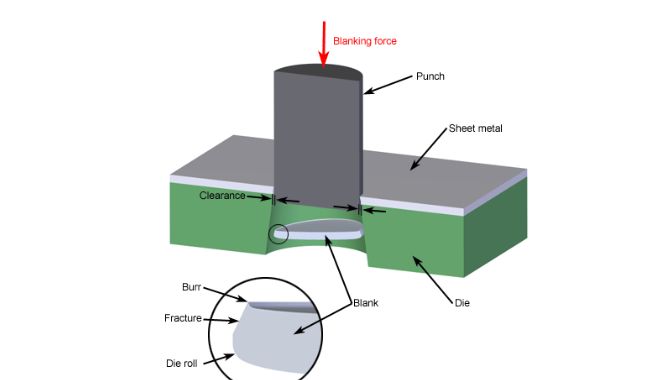

Now, this blanking ain’t just a one-step thing. It’s a bit more complicated than that. First off, the metal bends a little, like when you push on a piece of rubber. That’s what they call elastic deformation, fancy word for bendin’ but not breakin’.

Then, you push harder, and the metal starts to change shape for good, it ain’t gonna go back to the way it was. That’s plastic deformation. It’s like kneadin’ bread, once you knead it, it ain’t the same no more.

- First, it bends.

- Then, it stretches.

- And finally, it breaks.

And finally, you push hard enough, and the metal just gives way, it breaks clean. That’s the fracture part. And that’s how you get your blank. It’s all about pushin’ that metal past its limits, makin’ it do what you want.

So, why is blanking so important? Well, it’s a fast way to get the shapes you need. You can make a whole bunch of parts real quick, all the same size and shape. Think of all them metal things you see every day, from your car to your washing machine, chances are a lot of them parts were made with blanking. It’s quicker than sawing or snip-snippin’ with them tin snips, that’s for sure. Faster means more things made, and that means more money for the folks makin’ ‘em.

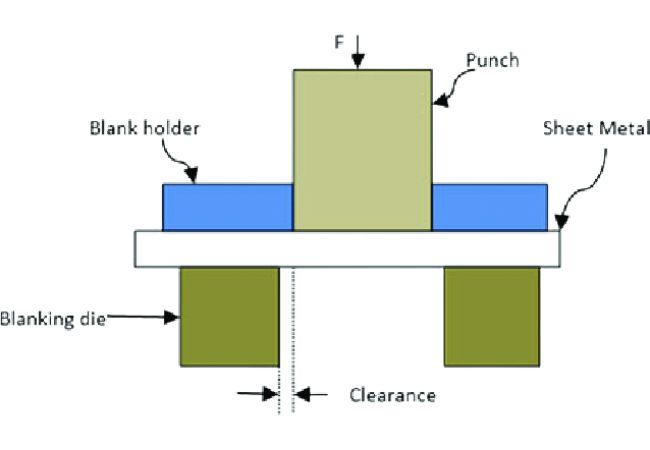

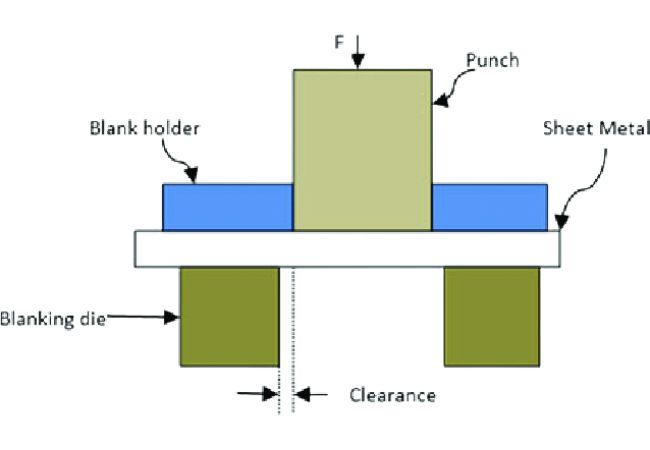

Now, the tools they use for this, they call ’em dies and punches. The die is like that cookie cutter, and the punch is what pushes the metal through the die. They gotta be tough, these tools, ’cause they’re dealin’ with some strong metal. And they gotta be precise, too, or your blanks ain’t gonna be the right size or shape. If things ain’t lined up just right, the metal might tear or wrinkle, and then you just got a mess and waste of time and money.

Different metals act different when you blank ’em. Some are easy, like butter, and some are tough as nails. You gotta know your metal, know how much force to use, what kind of die to use. It ain’t just one size fits all, no sir. You gotta have the right tools for the job, and you gotta know how to use ’em.

And there’s different ways to do this blanking thing too. Sometimes they do it cold, sometimes they heat the metal up a bit to make it easier to work with. It all depends on what kind of metal it is, how thick it is, and what kind of shape you’re tryin’ to make. Just like bakin’ a cake, gotta adjust your recipe dependin’ on what you got and what you want.

Blanking is a sheet metal operation, that’s the fancy way of sayin’ it’s a way of cuttin’ metal sheets. It’s all about cuttin’ a flat shape out of that sheet. And let me tell you, it ain’t always just a simple circle or square. They can make some real complicated shapes with blanking, all kinds of curves and angles. It just depends on the die they use.

So, next time you see a metal part, think about blanking. Think about that sheet of metal, and that punch comin’ down, and that clean break. It might seem simple, but there’s a whole lot of know-how that goes into makin’ it work right. And it’s important, too, ’cause it’s how they make so many of the things we use every day. Without blanking, well, things would be a whole lot different, that’s for sure. We wouldn’t have near as many shiny metal things, and where’s the fun in that?

And that’s about all there is to it. Blanking. It ain’t rocket science, but it gets the job done. You get your piece, and you move on. Just like life, I suppose. You take what you need, and you keep on goin’.