Steel slitting, well, it’s nothin’ fancy but it sure does get the job done. You take these big ol’ rolls of steel, all wound up tight like a big yarn ball, and run ’em through these special machines with sharp, round knives. Now, these knives, they’re tough, almost like them blades you’d use on the farm, but they’re set up to slice right through metal, so you can get the sizes you want. This whole thing, they call it “slitting.” Sounds simple, don’t it? But there’s a lot more goin’ on under the hood than you’d think!

What Exactly is Steel Slitting?

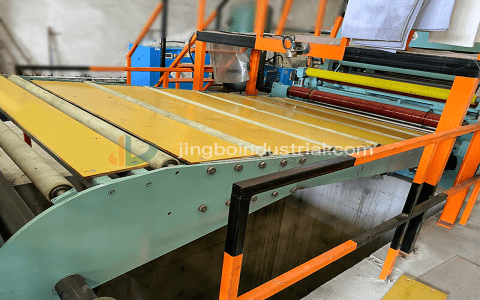

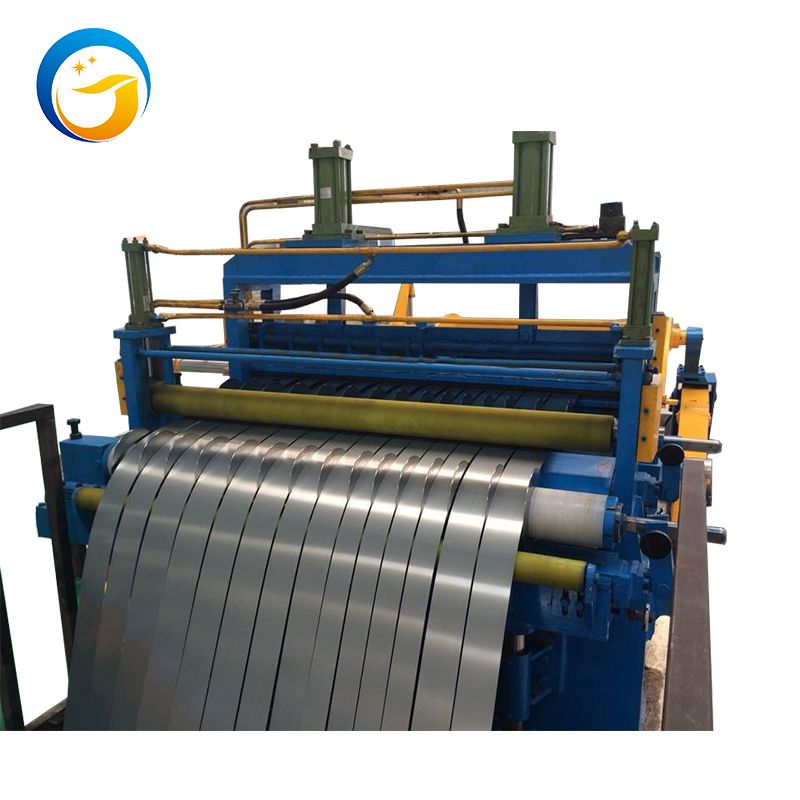

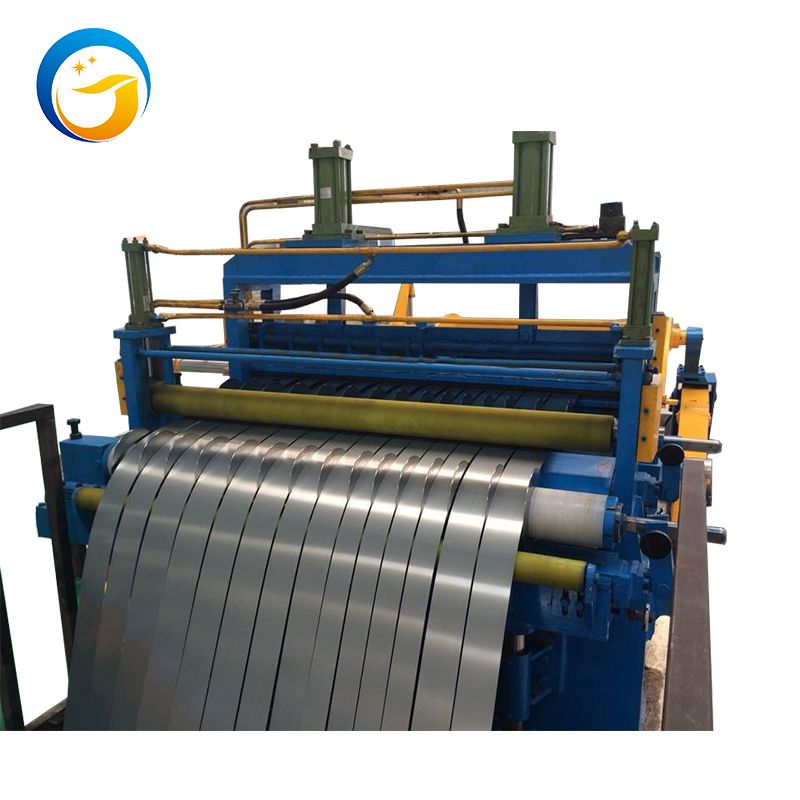

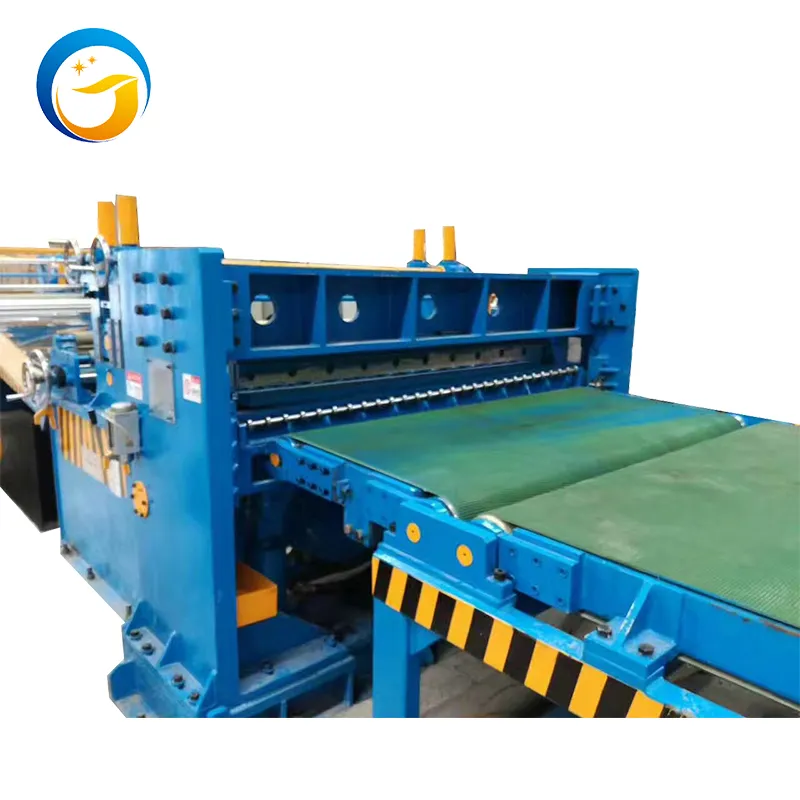

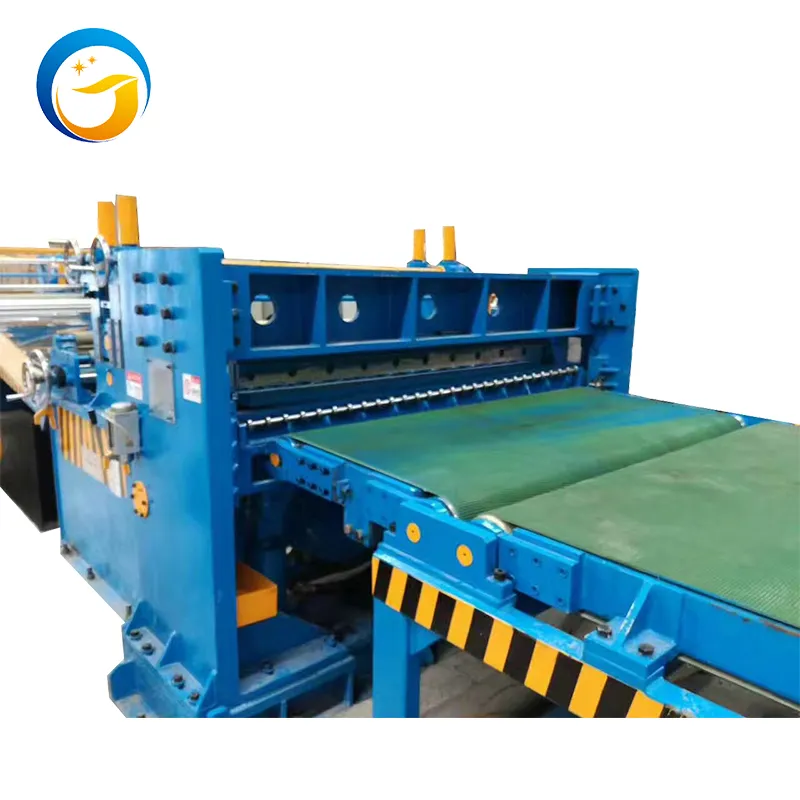

Imagine you got a wide piece of steel. Maybe it’s too wide for what you’re plannin’ to do with it, like if you’re makin’ little parts for machines or somethin’ smaller. So, what they do is put that steel on a machine that spins, kinda like a big ol’ clothesline. The steel coil goes through these round knives that are set up on two sides—one up top, one down low. As it rolls through, those knives split that steel right down to the sizes you need. Could be narrow, could be real skinny; they just set the knives to cut however wide or narrow you want it.

How Steel Slitting Works

- First, you start with a big steel coil, all heavy and thick, usually wide.

- Then it goes through a machine, which folks call a “slitter.” The slitter has blades set up, kinda like those old shears for sheep, only stronger.

- As the coil moves, those blades slice it up into the widths ya want. If ya need it narrower, they adjust the blades closer together.

- Then out comes these narrow strips of steel, all ready for whatever job’s next.

People in the business, they say it’s an important process. And it is! Without slitting, well, you’d just have these big ol’ coils sittin’ there, too wide for use. Now, once it’s slit, companies can use those pieces to make car parts, pipes, appliances—just about anything where metal’s needed.

Why Slitting Matters in Steel Production

So, ya might ask, “Why go through all this trouble?” Thing is, companies use slittin’ so they can get more from each coil of steel. You’re not wastin’ any extra material, and you’re gettin’ just what you need without messin’ around with too much cutting later on. Plus, it saves a lot of time. You can imagine, these big machines, like the ones from Red Bud Industries, they’re pretty quick, turnin’ out tons of steel in no time.

For folks workin’ with different thicknesses, they even got machines called “heavy gauge slittin’ lines.” These lines can handle thicker steel, still cuttin’ through it like it’s nothin’. Those machines have more power, more precision, and can work faster, givin’ factories what they need quicker.

Types of Steel Used in Slitting

Most of the time, they’re workin’ with steel, but they can slit all sorts of metals, too. Aluminum’s common, and sometimes even copper or softer metals. But with steel, you get all sorts of varieties: cold-rolled steel, hot-rolled steel, galvanized. Each kind is a bit different, so they gotta adjust the machines for whatever type of steel’s on the line. Some of these machines even handle steel with coatings, makin’ sure the edges stay smooth and clean after the cuttin’s done.

Getting the Right Width and Edge Quality

Another big thing is edge quality. Ya don’t just want any ol’ rough cut on these strips, especially if the steel’s goin’ into products where edges matter, like pipes or frames. The slittin’ machines, they use precision to keep those edges clean and even. That way, there’s less chance of sharp or jagged bits that could cause problems down the line.

The Importance of Cycle Time in Slitting

People in the steel industry talk a lot about “cycle time.” That’s just how fast the machine can take a coil and turn it into those strips. Faster cycle times mean more coils processed in a day. Some companies, like that Red Bud Industries I mentioned earlier, pride themselves on havin’ some of the quickest cycle times around, gettin’ more done with less waitin’. This helps keep up with all the demand, ‘cause everyone from car makers to construction folks wants their steel ready to go when they need it.

In Conclusion

So that’s steel slitting for ya. Start with a big ol’ coil, run it through sharp blades, and end up with smaller strips, all the right size and ready to use. It’s a simple idea, but one that keeps things movin’ in industries all over. From makin’ big stuff like bridges to little parts like screws, slittin’ helps make it all possible, and it does it fast, efficient, and just the way folks need it.

Tags: [steel slitting, steel production, metal slitting, coil processing, manufacturing]