Alright, let’s talk about ductile hot-rolled steel bars. Sounds a bit technical, right? Don’t worry, I’ll break it down in a way that’s easy to understand, like we’re just hanging out and chatting about materials.

So, picture this: you’ve got this steel bar, right? It’s been through the hot rolling process, meaning it’s been heated up to super high temperatures and then squished and rolled into shape. Think of it like kneading dough – it gets super malleable when it’s warm. Now, “ductile” just means that this bar can bend and flex without breaking. It’s like that bendy straw you get with your drink – you can twist it, and it doesn’t snap!

Now, this hot-rolled steel bar has a special strength – it can withstand a certain amount of force before it starts to deform. This strength is measured in something called “yield strength.” It’s basically the point where the steel bar goes from being a good sport and bending a bit to, well, starting to get grumpy and potentially breaking.

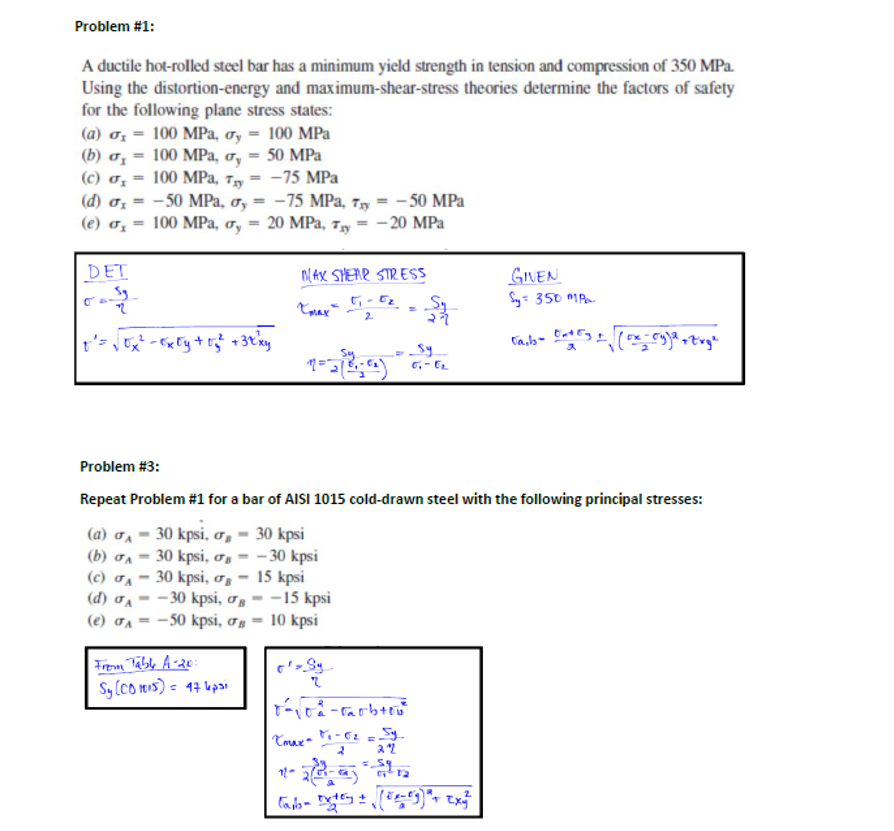

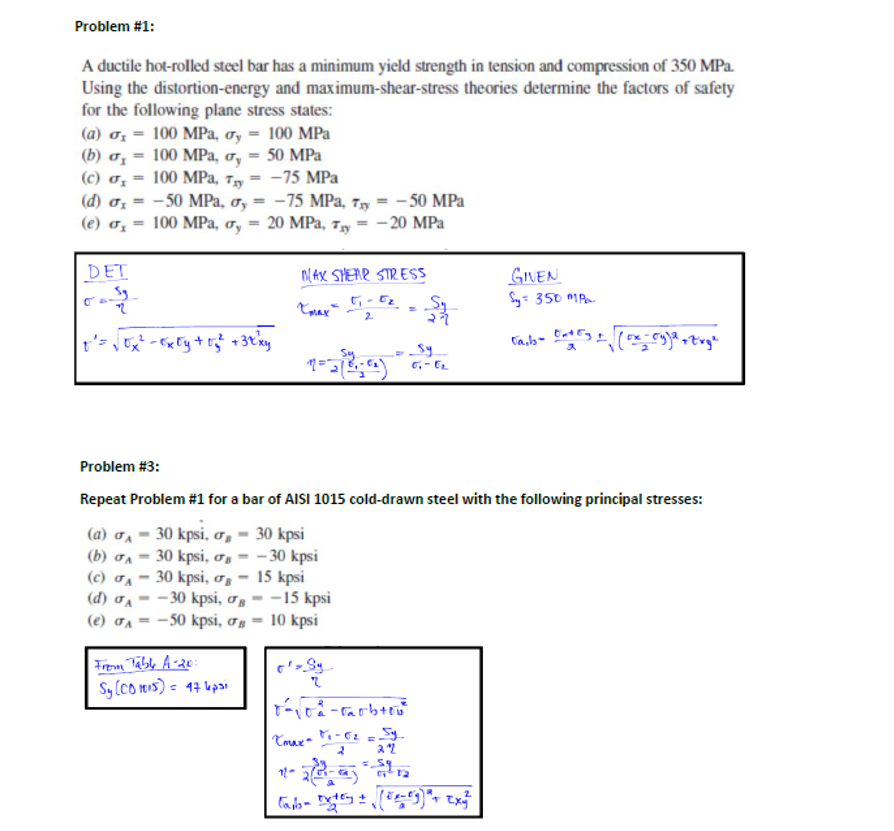

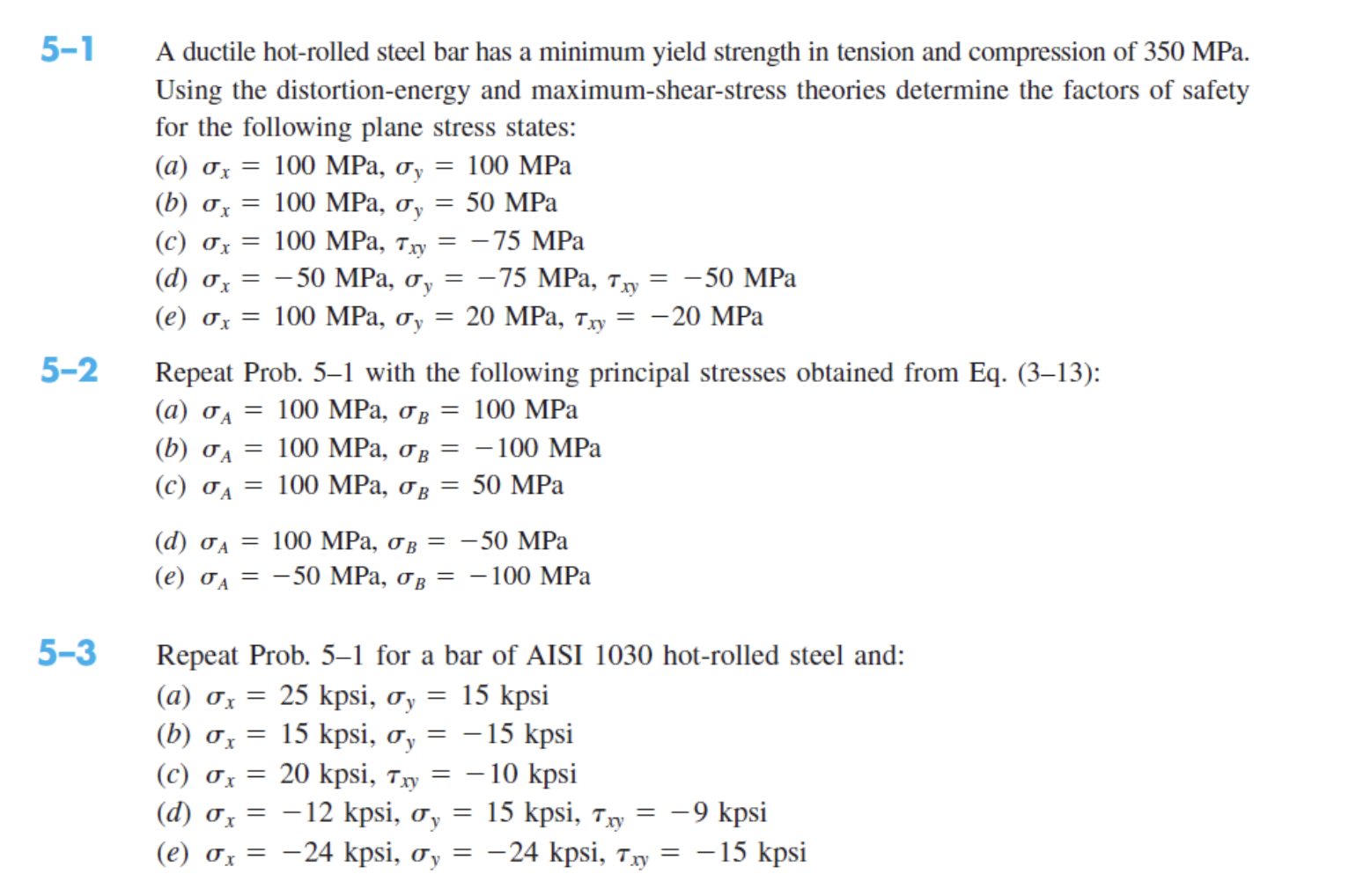

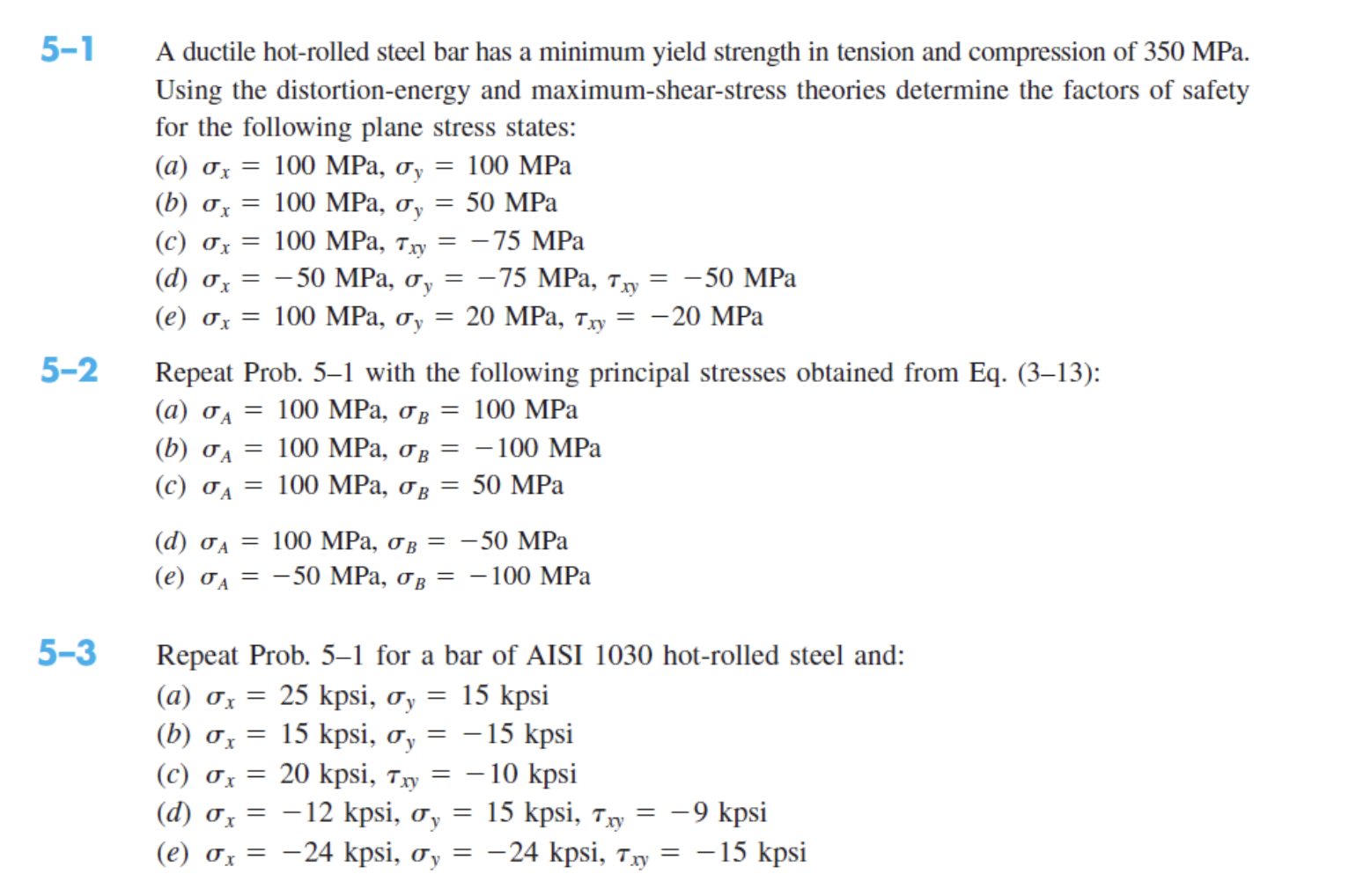

Let’s say this particular hot-rolled steel bar can handle a minimum of 350 MPa of force before it starts to complain. That’s a lot of pressure! To put it in perspective, it’s like holding up a car on your shoulders. Now, engineers use different formulas and theories to figure out how much pressure a steel bar can take in different situations. They have these cool things called “distortion energy theory” and “maximum shear stress theory,” which are like secret codes for understanding how steel behaves.

These theories help engineers determine what’s called the “factor of safety.” This is a number that tells them how much extra strength the steel bar has beyond what it needs to handle a specific job. So, if the engineer calculates that the bar needs to handle 100 MPa of force, and it has a yield strength of 350 MPa, the factor of safety is 3.5. That means the steel bar is super strong and can handle more than three times the amount of pressure needed!

Here’s a table that shows some examples of how the “distortion energy theory” and “maximum shear stress theory” are used:

| Stress State | σx (MPa) | σy (MPa) | Factor of Safety (Distortion Energy Theory) | Factor of Safety (Maximum Shear Stress Theory) |

|---|---|---|---|---|

| (a) | 100 | 100 | 2.45 | 2.83 |

| (b) | 100 | 50 | 3.16 | 3.54 |

| (c) | 100 | 0 | 3.54 | 4.00 |

As you can see, the factor of safety varies depending on the stress state. That’s because the forces acting on the steel bar are different in each case.

So, there you have it – a quick and easy explanation of ductile hot-rolled steel bars and the science behind their strength. Now, you’re ready to impress your friends with your knowledge of materials and how they work!

Have you ever wondered how engineers choose the right kind of steel for a specific project? What factors do you think they consider when selecting a steel bar for something like a bridge or a building?