Oh, you know, this pre-coated metal, it’s quite a thing nowadays. Fancy name, right? But it’s just metal that’s already got a nice coat of paint or protection on it before it even leaves the factory. Saves a lot of time and trouble, especially when you need metal that won’t rust or scratch up too quick. Makes a world of difference if you’re working with stuff like refrigerators, washing machines, you name it. Them companies, they use it because it lasts longer and don’t need as much fixing up.

Now, this pre-coated metal, or sometimes folks call it PCM, is a clever way of saving money and work down the line. You get a metal sheet, and they put a coating on it. Simple as that, you see? It’s not all shiny metal just plain; it’s like putting a little jacket on it. Keeps it safe from rain, wind, scratches – you know, the things that’d normally tear metal up over time.

What’s so special about pre-coated metal? Well, let me tell you, it’s got a few tricks up its sleeve:

- Weather-resistant: This stuff doesn’t rust up fast like normal metal, so it’s great for places where it rains a lot or gets real humid. Think of it as wearing a raincoat.

- Scratch-resistant: You don’t want your washing machine all scratched up, do you? Pre-coated metal is tougher, so it doesn’t get those ugly marks so easy.

- Safe to use: The coating isn’t just for looks – it makes the metal safer too. Some coatings even have less harmful chemicals, which is good if it’s for home use.

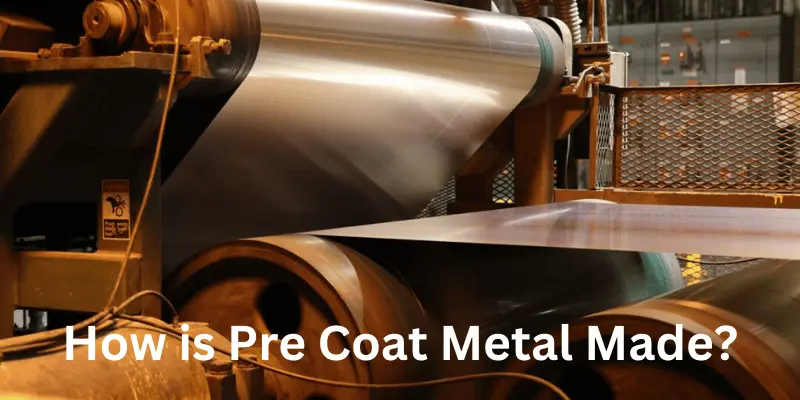

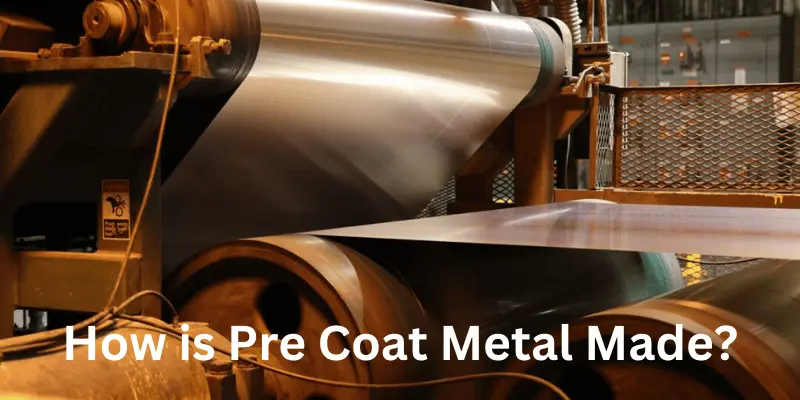

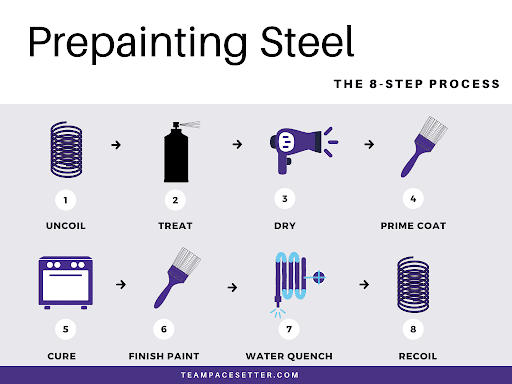

In the old days, folks would just slap on paint after they shaped the metal, but not with PCM. No, sir. They paint it before they even shape it, so it looks good and lasts longer. This makes it easier when companies are working with big machines. Just think – no need to paint every corner and edge after you bend and cut it; it’s already done for you! Big help, if you ask me.

Where’s pre-coated metal used? Well, in all sorts of places. Appliances like fridges, microwaves, washers – they’re all made with it. It’s also used for construction, like metal roofs and wall panels. See, those big factories, they use PCM because it’s quicker and easier, and it looks sharp. Some fancy buildings even have walls made out of pre-coated metal because they don’t need as much upkeep.

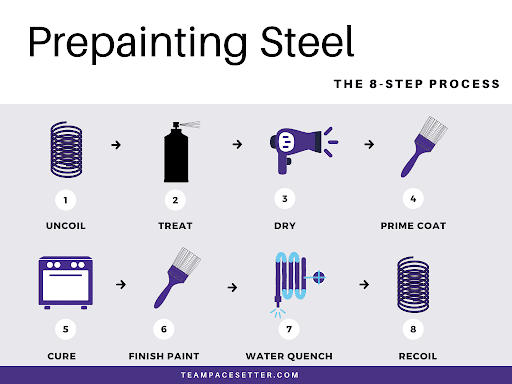

And let me tell you, it ain’t just about looks. They’ve got all sorts of coatings – not just paint. Some of it’s film coating, some use special chemicals to keep the metal from getting all rusty. People call it coil coating too, which just means putting the paint on while the metal is still in a big roll. Once that’s done, the metal can handle more beating, more bending, you know, and still keep looking good.

So, why all the fuss? Well, PCM makes things cheaper in the long run. The coating means companies spend less on repairs and replacements. Appliances made with it look new for longer, and construction folks don’t have to keep fixing rusty metal all the time. Plus, a lot of these coatings use lower chemicals now, which is better for the environment, they say.

So, if you see a fridge or a roof that looks spotless even after years of rain and shine, that’s probably pre-coated metal for you. It’s tough, lasts longer, and sure looks sharp too. No wonder they’re using it more and more. It may sound fancy, but really, it’s just good old-fashioned common sense.

Tags:pre-coated metal, PCM, coil coating, pre-painted metal, durable metal