So, ya wanna know ’bout material CRS, huh? Well, let me tell ya, CRS stands for “cold-rolled steel.” It’s not somethin’ fancy, but it’s strong, solid, and got its own uses all over the place, especially when ya need somethin’ sturdy.

What Exactly Is CRS?

Alright, lemme put it plain. CRS is steel that’s rolled and pressed at room temperature, see? Not heated or nothin’, which makes it tougher in some ways. Cold rollin’ means it comes out smooth and shiny-like, but also stronger in certain ways than that regular ol’ hot-rolled stuff. Cold rollin’ gets done after the steel’s already cooled down, so it don’t warp or twist much. This way, it stays real accurate in thickness and size, just how folks need it.

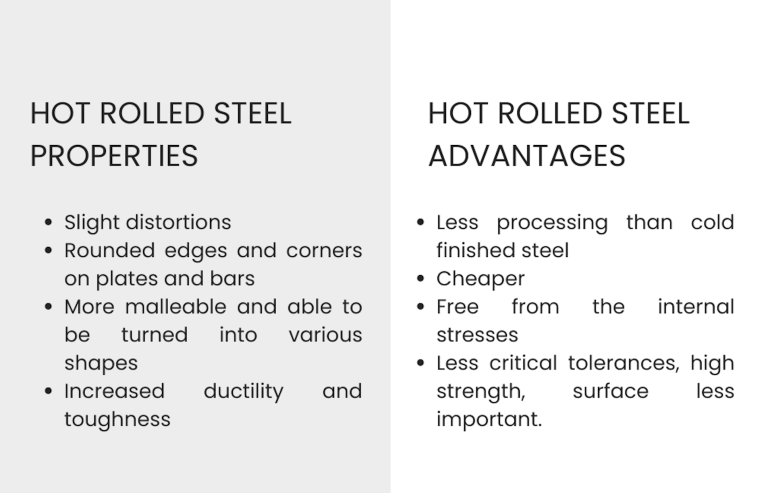

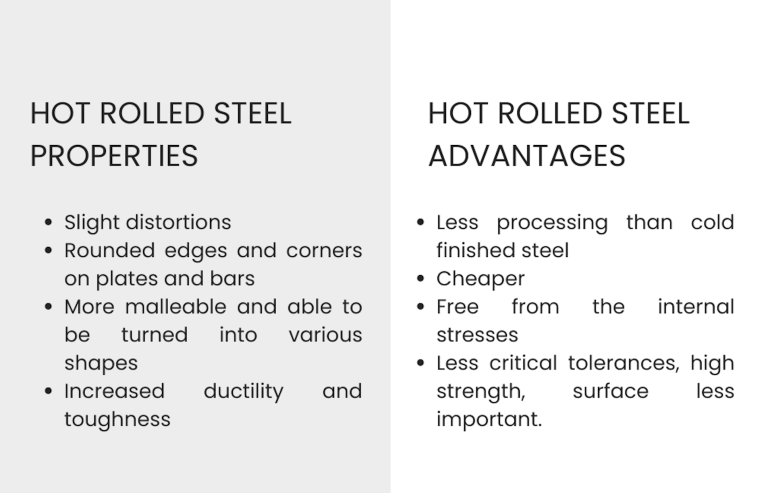

Why folks use CRS so much is ‘cause of its strength and finish. That smooth finish makes it better lookin’ and easier to paint or coat if ya need to. It’s what ya might call a “mild steel,” which just means it’s got less carbon in it, makin’ it easy to bend and shape without breakin’. So if yer makin’ parts that need to be bent or worked on, this CRS is what ya need.

Benefits of CRS Material

Now, let me break it down for ya:

- Strength: This stuff can handle a good amount of weight and pressure. Even if ya give it a real good knock, it’s not gonna just fall apart on ya. Mighty tough, that’s CRS.

- Easy to Shape: ‘Cause of that low carbon, it don’t crack or crumble. You can bend it, twist it, shape it however ya want.

- Smooth Finish: That cold rollin’ gives it a nice smooth look. Ain’t all lumpy and bumpy like hot-rolled steel.

- Corrosion Resistance: Well, sometimes it gets a coat or even galvanized (which means it’s got a zinc layer on it). Helps keep the rust off if it’s goin’ outside or near water.

Where Ya See CRS Bein’ Used

Folks use CRS for all sorts of things. Since it’s good for makin’ small parts where ya need precision, ya see it in car parts, like shims and frames. Shims, if ya don’t know, are those little bits that fill up space in parts so everythin’ stays put just right. It’s also good for makin’ things like shelves, beams, and those metal drawers ya see everywhere, since they stay nice and even.

Sometimes, folks like car makers and such might go for other materials like aluminum or plastic, but CRS has its own place ‘cause of that strength and easy shapin’. Aluminum’s good for lightweight stuff, but when ya need somethin’ real sturdy, CRS is yer best bet.

Types of CRS

Ya got a few different grades in CRS too, just so’s ya know. Common ones like 1018 or 1020 steel are big names here. They got different amounts of carbon and other stuff mixed in, but they’re all mostly soft, which makes ’em easier to shape. 1018 is a popular one since it’s so workable, while 1020’s got a bit more toughness to it.

When yer buyin’ CRS, ya might hear talk about “tempers” or “grades.” Don’t let that get ya all worked up; it’s just fancy talk for how tough or bendy it is. Some places also add a bit of zinc for protectin’ against rust, which they call “galvanized.” Keeps the metal from corrodin’ too fast if it’s left outside in the rain.

CRS Versus Hot-Rolled Steel

Alright, so what’s the big difference between this CRS and regular ol’ hot-rolled steel? I’ll tell ya plain: hot-rolled steel’s cheaper and good for bigger stuff where looks don’t matter. It’s also easier to make since they just roll it out hot and let it cool however. But it can end up warped or a bit rougher on the outside. Cold-rolled, like I said, is all smooth and precise.

So ya see, it all depends on what yer makin’. For rough and tough work like big ol’ beams, hot-rolled does fine. But if ya want parts to fit together smooth, CRS is the way to go.

Conclusion

Well, there ya have it. CRS, or cold-rolled steel, might seem simple, but it’s useful for a whole heap of things where ya need strength, a smooth finish, and ease of shapin’. From car parts to beams and shelves, it’s got a place all its own. So next time ya see a sturdy drawer or a car part that just don’t quit, reckon it might just be made from CRS.

Tags:

CRS, Cold-Rolled Steel, Low-Carbon Steel, Material, Metal Strength, Steel Applications