This here thing, plate metal thickness, it ain’t so simple, you see. Like pickin’ the right hog for slaughter, gotta know what you’re lookin’ for. Now, I ain’t no fancy engineer, but I’ve seen a thing or two in my time. You got your sheet metal, and you got your plate metal. One’s thin like my old curtains, and the other’s thick as a stubborn mule’s hide.

That thin stuff, sheet metal, they use it for all sorts. Easy to bend, like when you’re makin’ those fancy shapes for, well, I don’t know what they call ’em. But you see ’em around, all twisted and turned. This sheet metal, it ain’t much thicker than a good piece of paper, some of it. That’s best for things that need shaping, I reckon.

Then you got your plate metal. That’s the real heavy stuff. Think like, thicker than the sole of your best boots. That’s for the big jobs. Bridges and such, where you need somethin’ that won’t buckle under a heavy load. They use it for them big machines, too, the ones that dig and lift and all that. The stuff that needs to be real tough, you know?

Now, how thick is thick, you ask? Well, that’s where it gets a bit tricky. If it’s thicker than, let’s say, your pinky finger, maybe around 6mm or more like 1/4 inch, they call it plate metal. That’s the strong stuff for them big jobs, like I said. Buildings, them big metal boxes they carry on ships, that kind of thing.

- Sheet Metal: Thin like paper, good for bending.

- Plate Metal: Thick like your boot sole, good for strong stuff.

- Plate is over 6mm, about 1/4 inch, maybe as thick as your pinky.

- Sheet is under 6mm, thinner than your pinky.

If it is thinner than that, then it is sheet metal. That is easier to cut and bend. They use it to make cars, and cans, and all kinds of things. Now, I remember one time, my neighbor, he tried to use that thin sheet metal to patch his roof. Well, bless his heart, it didn’t hold up to the first good rain. Folded like a cheap suit, it did. Should’ve used the thicker stuff, that plate metal.

They got these fancy tools for measurin’ this stuff, too. One of them called a “caliper,” I think. Looks like a pair of tongs, but it tells you exactly how thick somethin’ is. Me, I just use my eyes and my hands. Been doin’ it that way for years, and it ain’t failed me yet.

If you are gonna order a big bunch of this metal, you best check it good first. Maybe get a little piece to look at before you buy the whole hog, so to speak. You don’t want to get stuck with a bunch of metal that ain’t right for what you need.

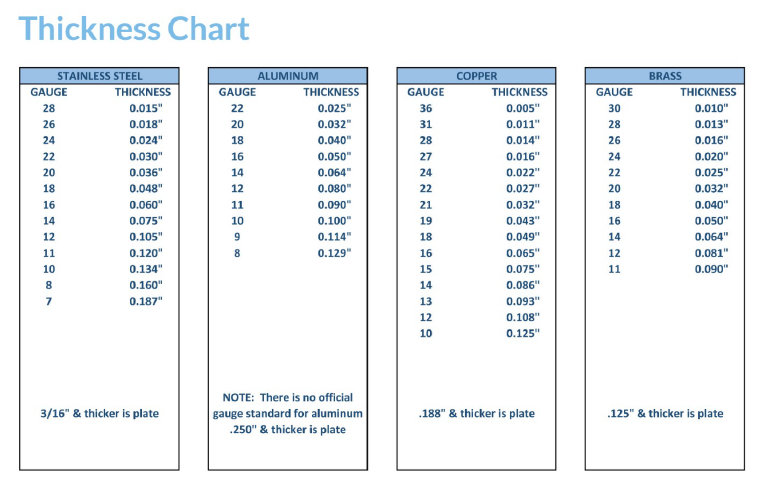

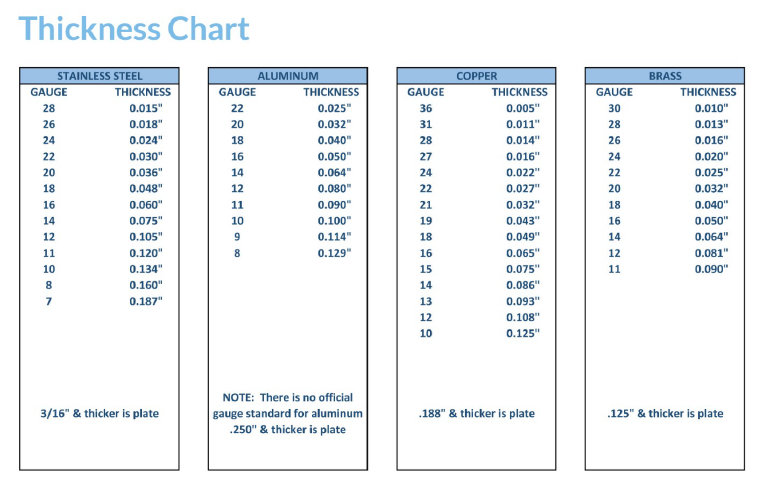

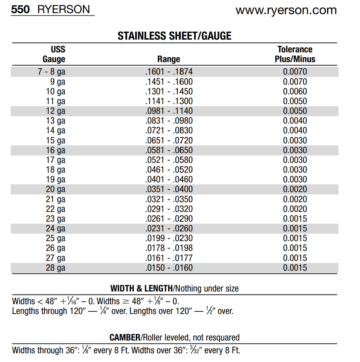

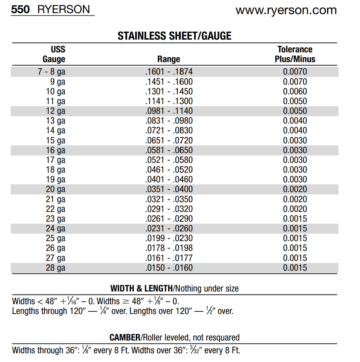

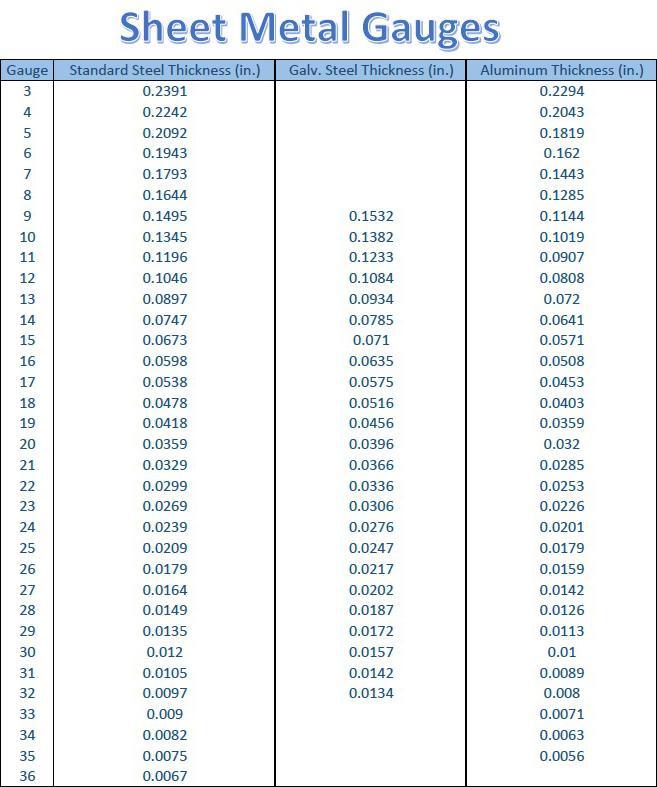

Different metals got different thicknesses, too, I reckon. Steel, aluminum, stainless steel that doesn’t rust, they all come in different sizes, like eggs from different hens. Best to know what you need before you go buyin’.

So, plate metal thickness, it’s all about what you’re gonna use it for. Need somethin’ strong? Go with the thick plate. Need somethin’ you can bend and shape? Go with the thinner sheet. And don’t be afraid to ask questions. Better to be safe than sorry, especially when you’re dealin’ with somethin’ as tough as metal.

Another thing to think about is where are you gonna get this metal? You got your steel, that’s real common. Then there is that shiny aluminum, and that stainless steel that they use in kitchens. Each one is different, like different kinds of pies. You would not want to use apple pie filling for a meat pie, right? Same goes for metal.

And these sheet metal gauges, they are like sizes for clothes. Higher number means thinner metal. Don’t ask me why, it just is. Like a size 10 dress is smaller than a size 2, a gauge 20 sheet is thinner than a gauge 10.

If you are doing some big project, you better know your metal plate thickness. You don’t want your bridge falling down or your building collapsing because you used the wrong stuff. That would be a real mess, wouldn’t it?

To figure out the thickness if you know other things, there is some kind of math involved. Something about volume and area. Now, I ain’t no good at that book learning, but I know there is a way to do it. If you got the volume, and you got the area, you can divide one by the other, and that will tell you the thickness. Maybe.

Choosing the right metal thickness, it is like picking the right seeds for your garden. If you want big, strong tomatoes, you gotta pick the right seeds. If you want a strong building, you gotta pick the right metal. It’s just common sense, really.

So, there you have it. That’s what I know about plate metal thickness. It ain’t rocket science, but it is important. Just remember, thick for strong, thin for bending, and always check your metal before you buy a whole bunch of it. And if you are ever unsure, just ask someone who knows. There’s no shame in asking for help, especially when it comes to something as important as this. Don’t be like my neighbor with his roof. Use your head, and you’ll be just fine.