Well, let’s talk about hot roll sheet. This is that kind of steel sheet that’s rolled at super high heat, around 1700°F or even more. It gets worked on in the mill while it’s hot and pliable, just like kneading dough but hotter. This process gives us steel that’s tough and strong but isn’t all fancy looking—just basic, practical stuff for projects where it don’t need to be pretty.

So, what is this hot roll sheet? Simply put, it’s steel that’s been heated up to real high temperatures to make it easier to shape. They start with these big ol’ slabs, known as billets, and shove ’em through rollers at high heat. That heat softens the steel right up so they can stretch and shape it into sheets. No need to be gentle with it—it can take it.

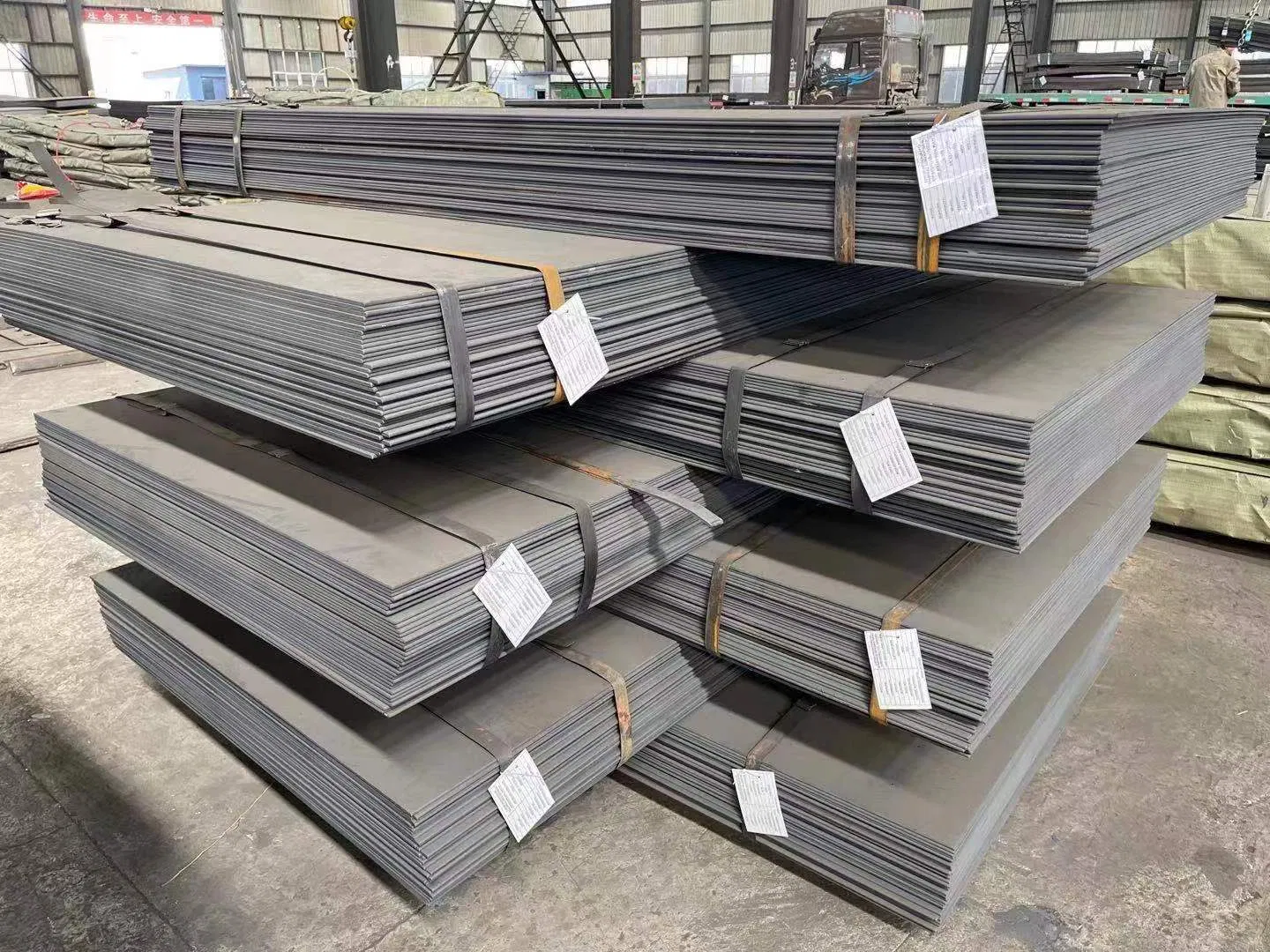

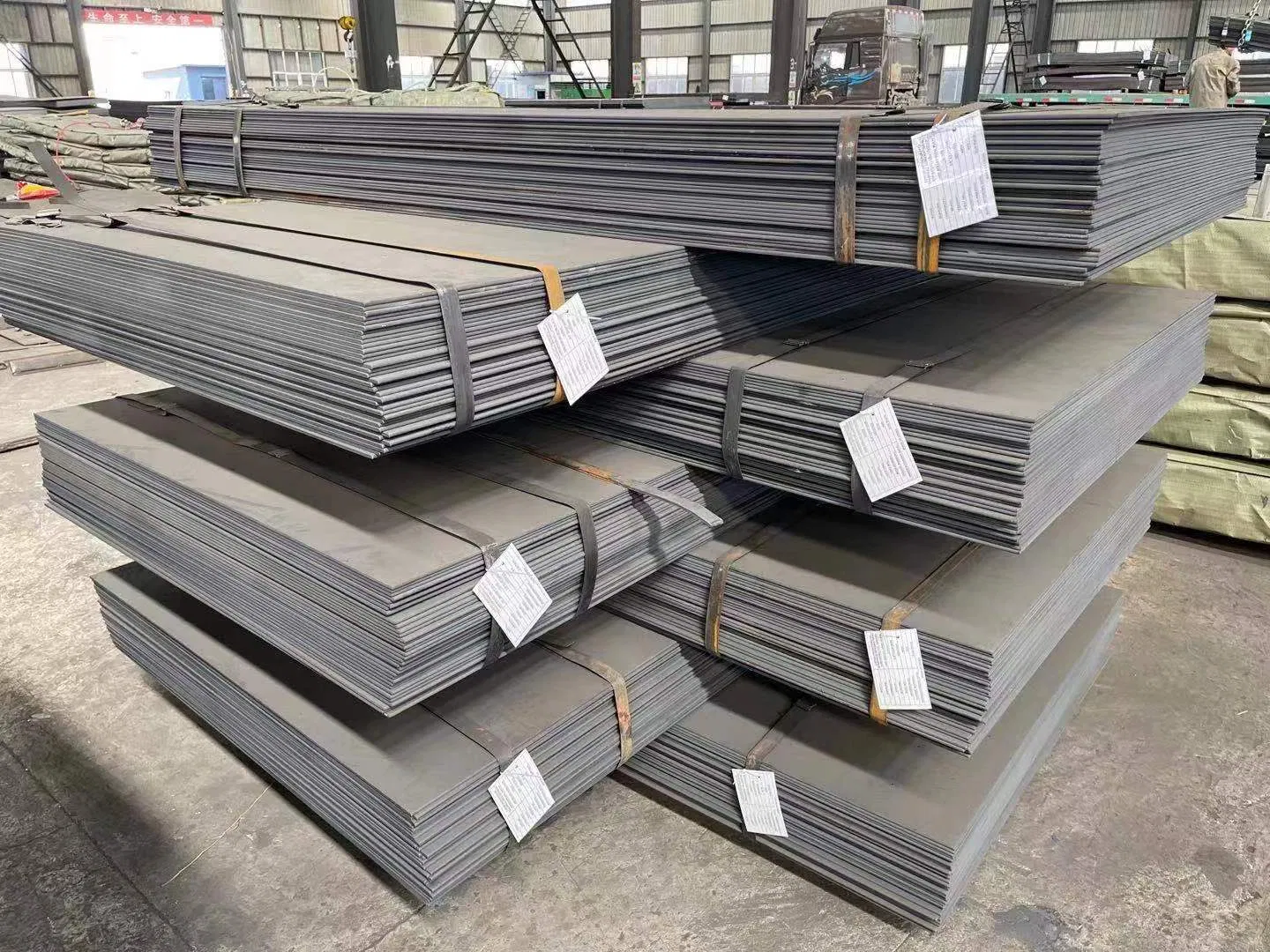

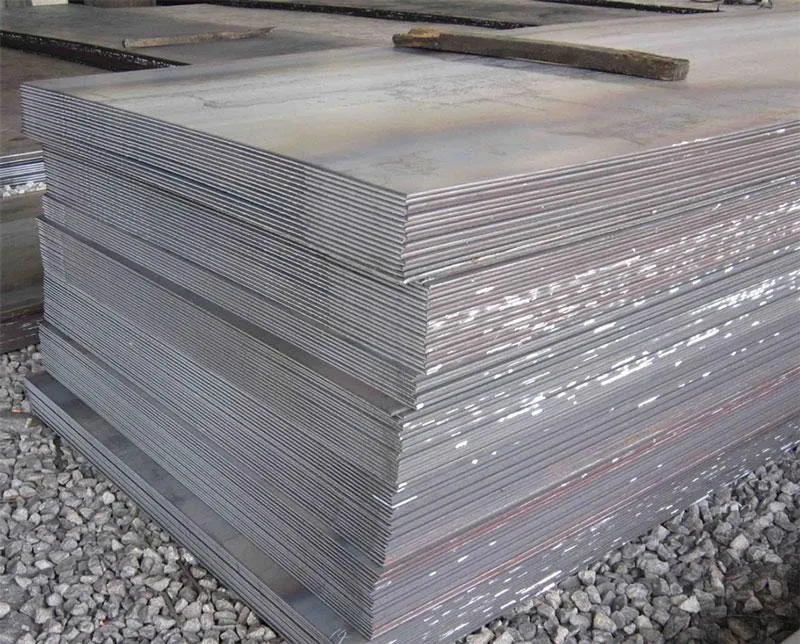

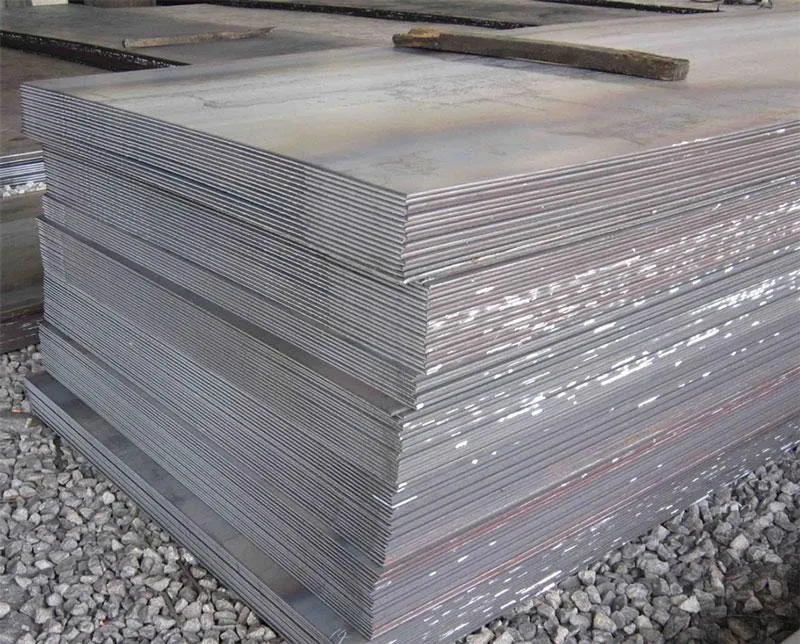

Now, this hot rolling makes sheets in all kinds of thicknesses, depending on what you need. Could be as thin as less than 1mm or beefy up to 25mm thick. No messing around here! This stuff’s made for real heavy-duty work. You might see hot rolled sheet used in things like construction, making parts for big machines, or other projects where folks need solid metal that won’t crack under pressure.

Why choose hot roll sheet over cold roll? Well, hot rolled steel is simpler and cheaper to make. Since it just needs that high-heat roll pressing, they don’t gotta spend extra time or money making it all smooth and shiny like with cold rolled steel. They let it cool down however it likes after rolling, so it might have a bit of a rough look, but that don’t matter much in heavy-duty work, right?

- Less Processing: Since it cools naturally, there’s no extra work needed.

- Cost-Effective: Hot roll is cheaper than cold roll because it skips the fancy polishing.

- Strong and Durable: It can take a beating without breaking down, which makes it good for tough jobs.

Some might ask, “Ain’t it better to have a smoother steel sheet?” Well, that depends. For things like car parts or appliances where looks matter, yeah, cold roll might be the way to go since it’s rolled at room temperature and gets extra polished. But if you’re building, say, a warehouse or heavy equipment, then hot roll does the trick just fine. Ain’t no one gonna inspect the beams holding up the roof for scratches, you know?

Another thing to know is that hot rolled steel changes size a bit as it cools. When it’s rolled hot, it’s all stretched out and big, but as it cools, it shrinks down a bit. So, if you’re making something that needs precise measurements, you might have to double-check the sizing once it cools. But for many folks, this small difference ain’t a big deal.

Also, hot rolled sheets can be easier to work with when you need to cut or weld them because they’re not as hard and brittle as cold rolled sheets. That little bit of roughness actually makes it pretty versatile in its own way. So, this hot roll sheet really does fit in a lot of projects, especially where durability and price matter more than looks.

So there you go! Hot roll sheet is strong, affordable, and tough as nails. It might not be polished, but it’s got its place in all sorts of heavy-duty projects. Whether you’re building something solid or just need reliable steel that won’t bust your budget, hot roll sheet’s got you covered.

Tags:[Hot roll sheet, hot rolled steel, steel sheet, heavy-duty steel, construction steel]