When it comes to making metal parts, we start right from a plain sheet, don’t we? This flat sheet, it’s called sheet metal. And, let me tell you, there’s a special step called blanking we do at the start. Oh, blanking is nothing fancy, just cutting that metal sheet to get pieces we need, like making dough pieces from rolled dough.

What’s This Blanking in Sheet Metal?

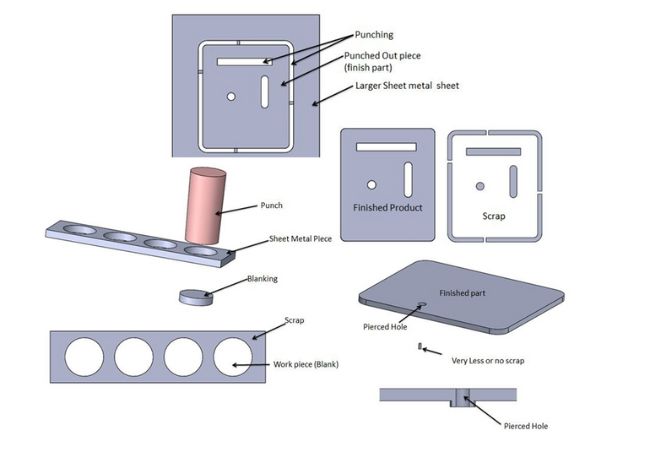

Blanking, let me tell you, is when you take that big sheet and slice it into smaller, flat pieces. These pieces, they’re all the same thickness as the sheet itself. Now, why we do blanking is, it saves time and keeps things neat and simple. You want a round piece, you cut out a round piece; you want square? Same thing. No waste left around. That’s what blanking is for.

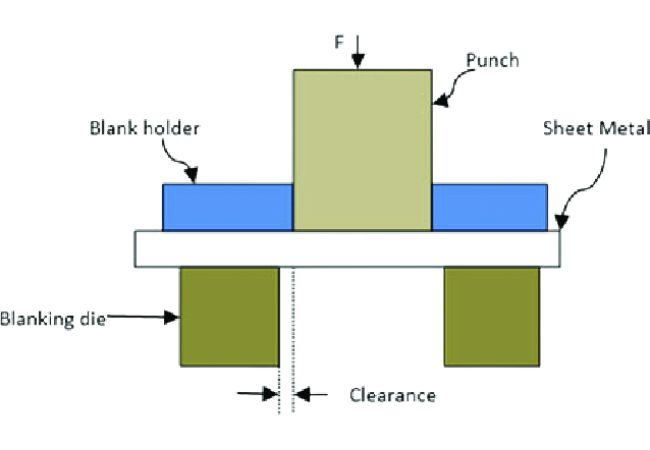

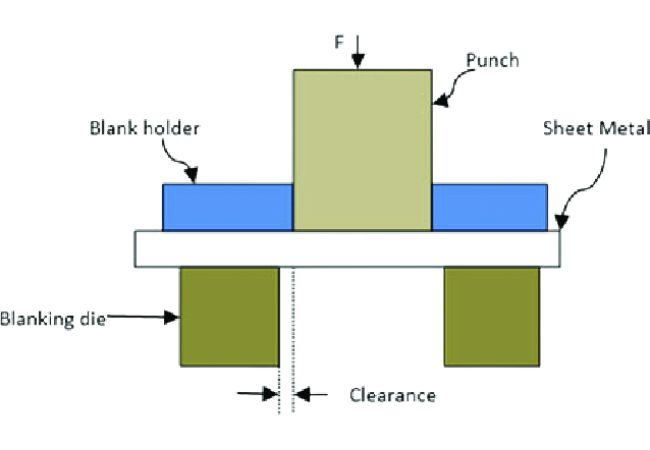

How Does Blanking Get Done?

Now, you might wonder, “How do they do blanking?” Well, it ain’t too complicated if you’ve got the right machines. These machines, they press down on the sheet, and with some real force too. So, with one punch, out comes the blank, all clean cut. No extra cutting needed. They got big machines, like press machines, and they got tools too, like dies. Oh, dies are just molds, but strong ones, for that metal to cut around.

Benefits of Blanking

Now, you might think, why even bother with blanking? Well, let me tell you the reasons.

- Efficiency – With blanking, you get each piece just right. Saves time, saves effort.

- Low Waste – Ain’t no need for extra cuts and trimming. You cut, and there you go, nothing wasted.

- Accuracy – Each blank, if cut right, will be the same as the others. No need to worry about different sizes.

So, you see, blanking does the trick to keep things quick and even. They get that blank to go into the next step without much fuss.

Uses for These Metal Blanks

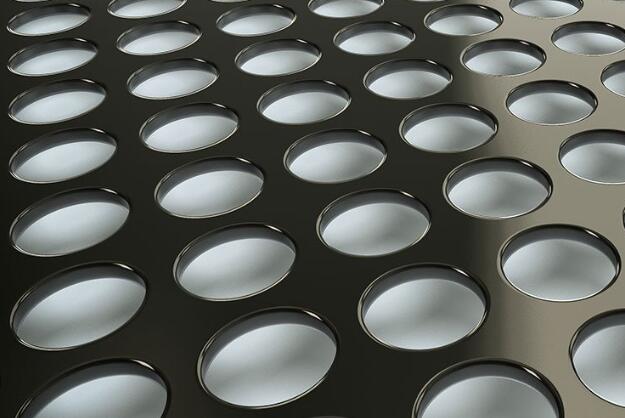

Now, what are these blanks good for? Lots of things, really! Once you got these blanks, you can bend ’em, punch holes, shape ’em up however you like. These blanks get used for things like car parts, kitchenware, and even electronics. Each blank is like a base piece, ready for whatever shape it needs to become.

Different Types of Blanking

Now, there ain’t just one way to do blanking, no. Different ways for different shapes. Here are a few:

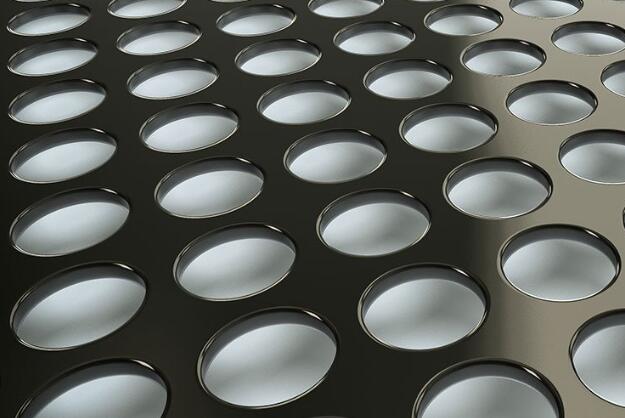

- Fine Blanking – This one’s for real smooth edges, you know. Cuts sharp and clean, like slicing with a sharp knife.

- Conventional Blanking – Just regular cutting, nothing fancy. Good for plain shapes.

- Progressive Blanking – This one’s where it cuts in steps, not all at once. First a rough shape, then more details.

Each type has its own job, like using different spoons for soup or tea. Fine blanking is for real neat parts, like for watches and stuff. Progressive blanking, you’ll see, is for shapes needing more than one step, like more detailed car parts.

Materials Best for Blanking

Not every sheet metal’s good for blanking, you see. We mostly use steel and aluminum. They’re strong enough but not too tough. You don’t want metal too soft either, or the piece will bend out of shape. So, metals like mild steel, stainless steel, and even brass are good for blanking.

What to Watch Out for in Blanking

Now, let me tell you, not everything goes smooth with blanking. Sometimes, there’s what they call burrs — rough edges that need to be filed off. Burrs come if the punch isn’t sharp enough or if the metal’s too thick. Also, you gotta set that machine pressure right. Too low, it won’t cut through; too high, you’ll damage the metal. So, gotta keep an eye on all this.

End Thoughts on Blanking in Sheet Metal

So, blanking, it’s a small step, but you can’t skip it. No blank, no part. Whether it’s car parts, small gears, or cookware, blanking starts it all. It’s like the dough-cutter for the baker, making every piece just right before shaping it up. Now, I might not be a machine expert, but I know blanking’s as important as any step in metalwork. There you have it — the ins and outs of sheet metal blanks done plain and simple.

Tags:[Sheet Metal, Blanking Process, Sheet Metal Cutting, Metal Fabrication]