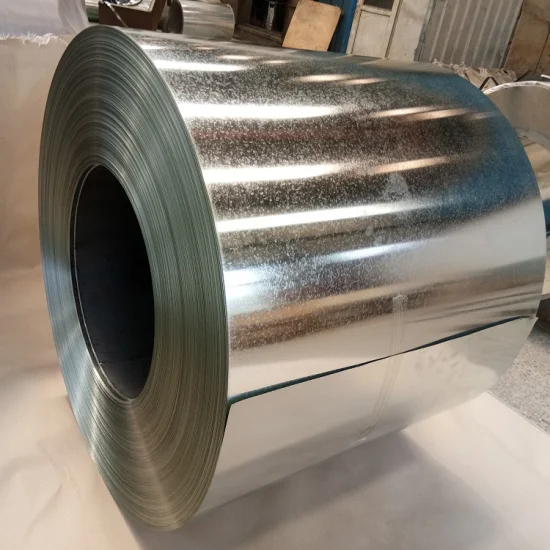

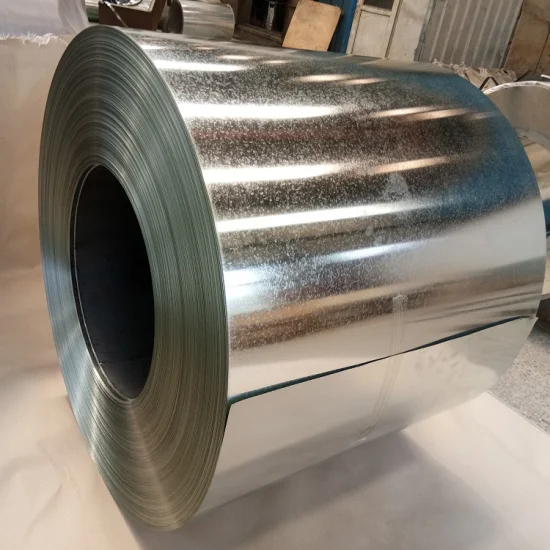

Oh, this galvanized steel coil they call GI, well, it’s somethin’ mighty useful if you need metal that won’t rust easy. That’s the biggest thing – that zinc coating on it keeps it tough, keeps it from wearin’ down or rustin’ like other metals. People don’t wanna keep fixin’ or replacin’ metal all the time, you see. When they slap that zinc on the steel, it’s called “galvanized.” So, you end up with a strong piece of metal that’ll last a good while longer, rain or shine.

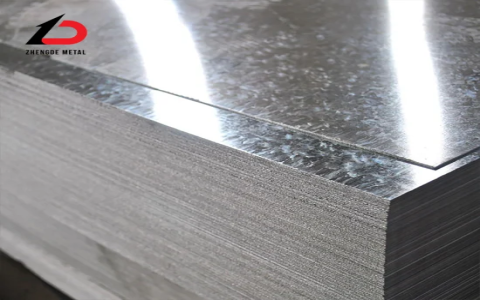

What’s so special ‘bout this GI steel coil? Well, first, let me tell ya, it’s got layers. That zinc coat is like a shield – keeps all that rust off. They put that zinc on by dippin’ the steel into some hot, molten zinc bath. Some folks call this “hot-dip galvanization.” This process makes the coat thicker, helps it stick on better, so the coil is tough as nails. Now, there’s a thinner kind too, where they use electric current to coat the steel; it’s called electro-galvanization. This type gives ya a smoother finish, but that coat is thinner. Both ways give ya zinc-coated metal, just a matter of how thick you want that protection.

So, where are folks usin’ these GI coils? Let me tell ya, they’re goin’ everywhere. A lot of builders love ‘em ‘cause these coils go into roofs, walls, and even fencing. The zinc keeps the rain and rough weather out, so things don’t wear out too quick. In big factories and places makin’ machines, they like GI ‘cause it stands up against moisture and chemicals, won’t be needin’ too much upkeep. And not just builders – folks makin’ household appliances use ‘em too, like the back of a fridge or inside a washing machine, ’cause ya don’t want those rustin’ neither.

What’s this GI coil made of? It’s all steel inside, but that coating makes it different. Now, if ya talkin’ galvanized aluminum, that’s a whole other story – that one’s based on aluminum, not steel. GI is all about the steel, and it’s made strong. They use cold-rolled steel – that’s steel that’s been pressed and cooled, makin’ it smoother and stronger, and then coat it with zinc. That’s what gives it the durability to last.

Standards and Quality

- EN 10346: Now, in Europe, they got a rule for makin’ this galvanized steel, called EN 10346. That just means the coil’s gotta meet certain standards to be strong and long-lasting.

- ASTM A653 / A653M: Over in the U.S., folks go by ASTM standards, A653 or A653M. This here makes sure the zinc coat is thick enough, the steel tough enough, and that it all works just right.

- DSTU EN 10346: This one’s used over in Ukraine, followin’ similar standards to make sure the coil’s got that good quality zinc coverin’ and a strong steel core.

Sizes and Thicknesses

These GI coils ain’t one-size-fits-all. They come in different sizes and thicknesses, dependin’ on what you need ‘em for. If it’s for a roof, you might need somethin’ a little thicker to hold up. For a fence or wall, maybe somethin’ thinner to save on weight. The makers give folks options, so you can pick what’s right for your job.

Why Folks Go for GI Steel Coils

End of the day, folks pick GI coils for the durability. If ya want somethin’ that can stay outside, handle a storm, and not rust easy, this is what ya get. The zinc coating is like armor for the steel, keepin’ it safe from the rain, wind, and other troubles. Builders know that if they’re usin’ GI steel, they’re addin’ years to their projects. So, whether it’s a big ol’ building, a small shed, or even the body of a truck, that GI steel coil is a good choice to keep things sturdy.

So there ya have it – that’s what makes galvanized steel coil, or GI, a favorite. It’s got that protection, that durability, and it sure don’t give in easy to rust. Builders, factory owners, and even folks at home know it’s worth puttin’ in, ‘cause it won’t let ya down anytime soon!

Tags:[galvanized steel coil, GI steel, zinc coating, rust protection, building material]