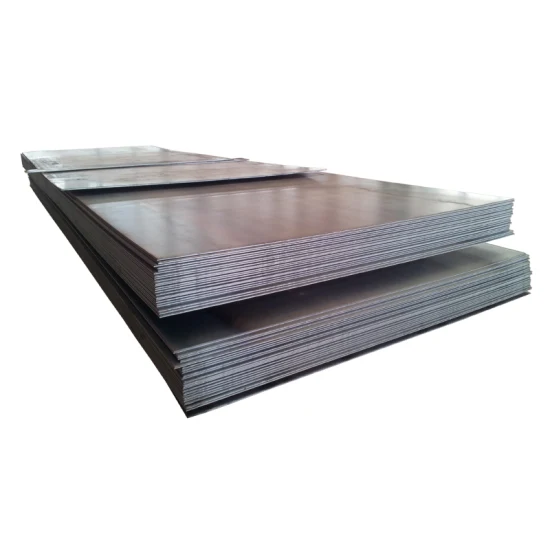

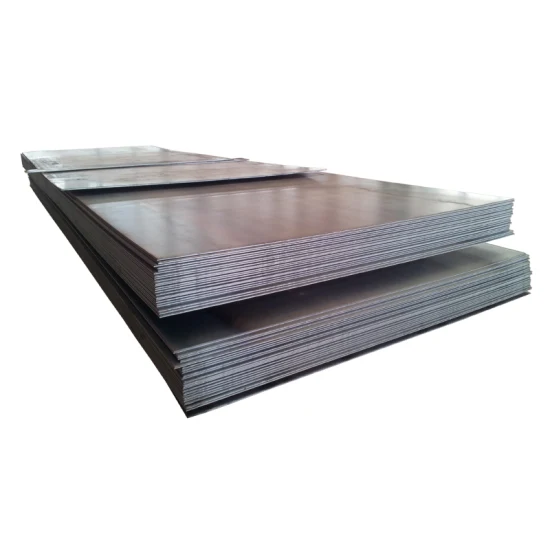

Alright, let’s talk about HRS, or Hot Rolled Sheet Metal. Now, I know what you’re thinking: “Sheet metal, boring, right?” But hold on! There’s more to it than meets the eye. Think of it this way: HRS is the backbone of countless products you use every day. Cars, appliances, furniture, even your trusty old bicycle – it’s all made possible, in part, by this versatile material.

So, let’s get down to the basics. HRS is just steel that’s been rolled at high temperatures. Imagine a giant metal pancake being squished flat – that’s kind of what’s happening! This process makes it strong, durable, and, most importantly, affordable.

Now, you might be wondering, “Why is it so popular?” Well, HRS has some real advantages:

Cost-Effective: It’s the most affordable option compared to other types of steel. Think of it as the value meal of the metal world!

Versatile: You can shape it, bend it, and cut it into all sorts of things. It’s like a blank canvas for your engineering dreams!

Strong and Durable: This stuff is built to last. It can handle a lot of stress and strain, making it perfect for heavy-duty applications.

But like any good friend, HRS also has its downsides. It’s not always the best choice for every situation:

Rough Surface: It has a somewhat rough surface compared to its smoother cousin, cold-rolled steel. Think of it like the difference between a well-polished table and a raw wooden plank.

Less Accurate Dimensions: Because of its manufacturing process, HRS can have variations in thickness and dimensions. So, if you need something super precise, you might want to consider other options.

So, when would you use HRS? Here’s a quick breakdown:

| Application | Use HRS | Use Other Types of Steel |

|---|---|---|

| Structural components in buildings and bridges | ||

| Automotive parts | ||

| Industrial machinery | ||

| Appliances | ||

| Furniture | ||

| Precision parts | ||

| Decorative items | ||

| Items requiring a smooth finish |

Now, you might be thinking, “This is great, but what if I need something a little more polished?” That’s where other types of steel come in, like cold-rolled steel. They are treated with additional processes to give them a smoother surface and more precise dimensions. Think of them as the gourmet meal of the metal world.

But ultimately, the decision comes down to your project and your budget. HRS is a reliable workhorse, offering affordability and strength. If you need a little more sophistication, you might want to explore other options.

Let me know if you have any questions. I’d love to hear your thoughts on HRS and how you’ve used it in your own projects!