Now, let me tell ya somethin’ about steel blanking. Folks who work with metal, they know this stuff, but for most of us, it’s like – what in the world is blanking, right? Well, I’ll try to explain it as simple as I can. Ya see, blanking’s all about cutting steel sheets into specific shapes and sizes, like makin’ dough into cookies, but with metal. It’s one of the first steps when they’re workin’ with big rolls of steel, called coils.

They take these big steel coils, which are heavy as can be, and feed ‘em into a machine. Now this machine, it’s got a die – think of it like a fancy cookie cutter but tougher than nails. The steel coil goes through this machine and, bam! The machine presses down and cuts out a piece of steel, called a “blank.” That blank is flat and usually a certain shape or size they need for makin’ other things later on.

Why Steel Blanking is So Important

Now, ya might be wonderin’, why go through all this trouble just to cut a piece of steel? Ain’t there a simpler way? Well, turns out blanking’s actually pretty important for folks who work with metal. See, these “blanks” get used to make all sorts of things – car parts, appliances, construction materials, you name it. And if the blank ain’t cut right, well, it won’t fit where it’s supposed to go later on. That’d be a problem, don’t ya think?

What’s neat is that blanking makes the job faster. With these blanks ready, companies don’t gotta waste time cuttin’ everything by hand, which would take forever. And because they cut these blanks just right, there’s less scrap metal wastin’ away. It helps save money, too – some folks say by about 15% if they use fancy machines like fiber lasers with coil feeding systems.

How Steel Blanking Works

- Step 1: First thing they do is take that big ol’ steel coil and unwind it. Gotta get it flat and straight so the machine can work on it proper-like.

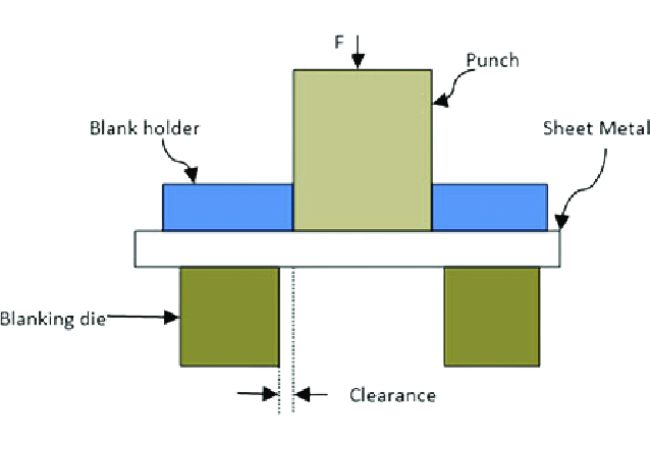

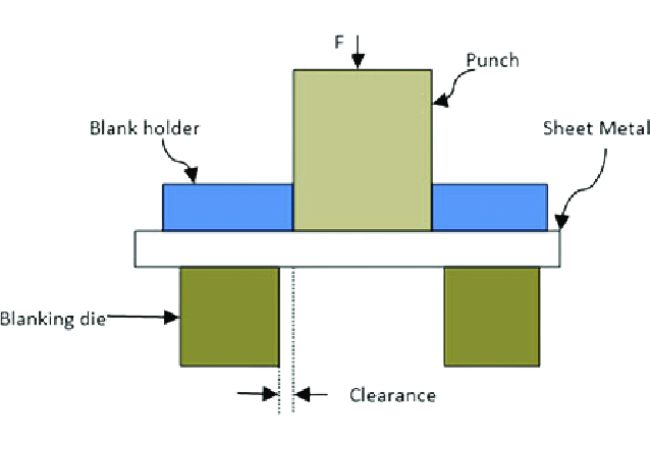

- Step 2: Once it’s flat, they feed it into this machine with a die. Now, the die’s what does the cuttin’. It presses down on the steel and chops out pieces in the shape they need.

- Step 3: The machine then cuts these blanks to the right length and size, corner-to-corner, just like trimmin’ fabric to fit a pattern.

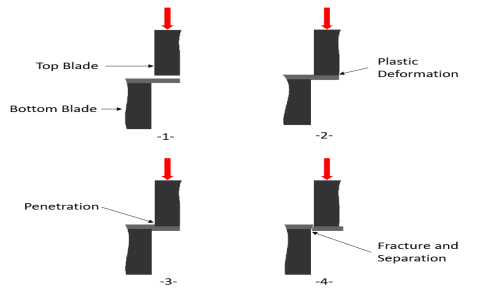

Now, some places got what’s called a “precision blanking” system. That’s where they cut the steel real exact, down to the tiniest bit, like 0.0003 inches! Takes a lot of pressure, and it’s like they’re squeezin’ the steel just so. They use a couple of different forces here: one to hold the steel in place, another from underneath, and then the final push to cut it all through. It’s no easy job, let me tell ya.

Different Kinds of Blanking

Steel blanking comes in all shapes and sizes dependin’ on what folks need. Now, the basic one’s what I just told ya about, where they cut the steel with a press. But they got other types too, like fine blanking, which I mentioned. That one’s for parts that gotta be extra precise. There’s also progressive blanking, where it cuts the metal in steps, and combination blanking where they combine blanking with other processes like stamping to speed things up.

Advantages of Steel Blanking

Now, ya might wonder, why don’t folks just cut metal by hand or use simpler tools? Well, there’s a bunch of reasons why steel blanking makes things a whole lot easier:

- Saves Time: Machines cut faster than folks can, so parts are ready lickety-split.

- Reduces Waste: Since blanks are cut to fit just right, there ain’t much leftover scrap.

- Saves Money: Because it’s efficient, companies save costs, sometimes by a good 15% if they’re smart about it.

What’s more, blanking lets factories make the same part over and over, all lookin’ the same, so the quality stays good. If ya need a car part or a bracket for somethin’, ya want it to be made just right, right? That’s what blanking does – it keeps the quality high and things lookin’ sharp.

Future of Steel Blanking

Now, as things keep gettin’ fancier, folks are always lookin’ for ways to make blanking even better. With new machines like fiber lasers and coil feeding systems, they’re able to cut blanks even faster and use even less metal. It’s amazin’ how these newfangled gadgets work, really. So in the future, ya can expect blanking to be even faster, more precise, and cost-effective. Who knows, maybe one day they’ll find a way to make it even cheaper and quicker for everyone.

So there ya have it! Steel blanking might sound like somethin’ fancy, but it’s just cuttin’ pieces of metal to size. A simple idea but mighty important for all sorts of industries. Whether it’s for cars, appliances, or buildin’ materials, blanking’s what gets those steel pieces just right, so everything fits and works like it should.

Tags:[steel blanking, steel manufacturing, blanking process, sheet metal, precision blanking, coil feeding system]