[

So, let me tell you about these rolling mills, you know, them hot rollers. They’re real handy for making steel, just like how folks around here make their flatbreads. You take a chunk of steel, all hot and ready, and you run it through these big rolling machines. They squish it down, make it thinner, and shape it up just right.

Now, hot rolling is the name of the game here. They heat that steel up real good, above what they call the recrystallization temperature. Sounds fancy, huh? But it just means they get the metal nice and soft so it can be worked with. Think of it like dough; you can’t roll it out cold. So, they put it through those rollers, and the steel changes shape without losing any bits. No scrap wasted, all gets used up!

These machines don’t just pop up overnight, either. They been around since way back, even before I was born! The first rolling mills, they say, showed up in the Middle East and South Asia around 600 BCE. Now that’s ancient! Can you imagine? But then, in Europe, folks like Leonardo da Vinci had a hand in improving these rolling mills. Gotta love the old geniuses, right?

Now, rolling mills used to be powered by water wheels. Yes, water! Ain’t that something? But then came along steam engines, like John Wilkinson’s works back in 1786, and they changed everything. Modern times, I tell ya!

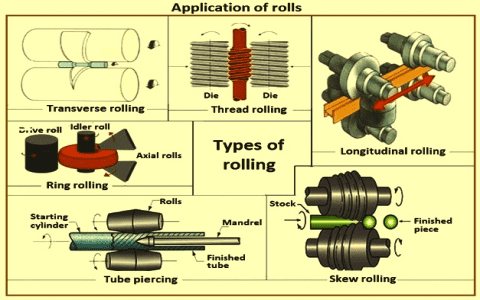

When you talk about rolling, it ain’t just one way to do it. You got hot rolling and cold rolling. Hot rolling happens when that steel is all heated up, making it easier to shape. But if the temperature’s not even, watch out! You might end up with uneven thickness, and that can cause all sorts of trouble. Just like when you try to make bread and one side’s doughy and the other’s burnt!

Let me tell you, there’s all kinds of metals that get rolled, too. Not just steel, but copper and brass have been rolled for a long time now. They even rolled lead back in the day. Rolling mills are so important, they make all sorts of things for us. You ever seen the metal sheets they use in construction? All thanks to these hot rollers.

What’s nice about hot rolling is that it helps give the metal certain properties, too. It can make it stronger or give it that nice, smooth finish. Just like polishing up your best dishes for a feast! You want everything looking nice, right?

But, with every good thing, there’s gotta be a few hiccups. Sometimes, if that steel doesn’t get heated just right, it can create defects. Like, if one side gets hotter than the other, then it won’t roll out evenly. That’s why folks gotta keep an eye on the temperature. Just like you keep an eye on your pot of stew, so it don’t burn!

In the end, hot rolling mills are a big part of how we get our metals shaped up for all sorts of uses. Whether it’s for making buildings, tools, or even just good ol’ metal sheets for roofing. They’re the unsung heroes of the metalworking world, if you ask me.

So, if you ever think about steel or any metal, just remember these hot rollers are working hard behind the scenes, making sure everything comes out just right. And that’s the long and short of it!

]

Tags:[rolling mill, hot rollers, steel production, metalworking, hot rolling process, machinery]