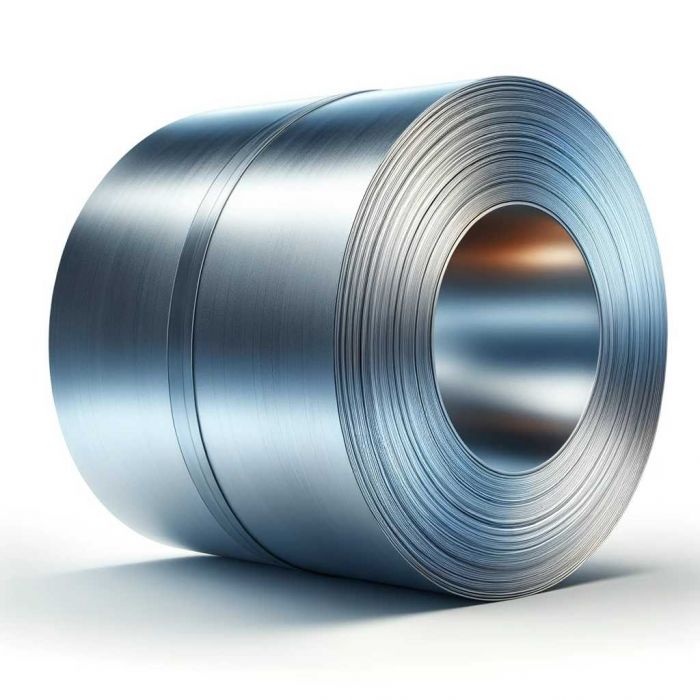

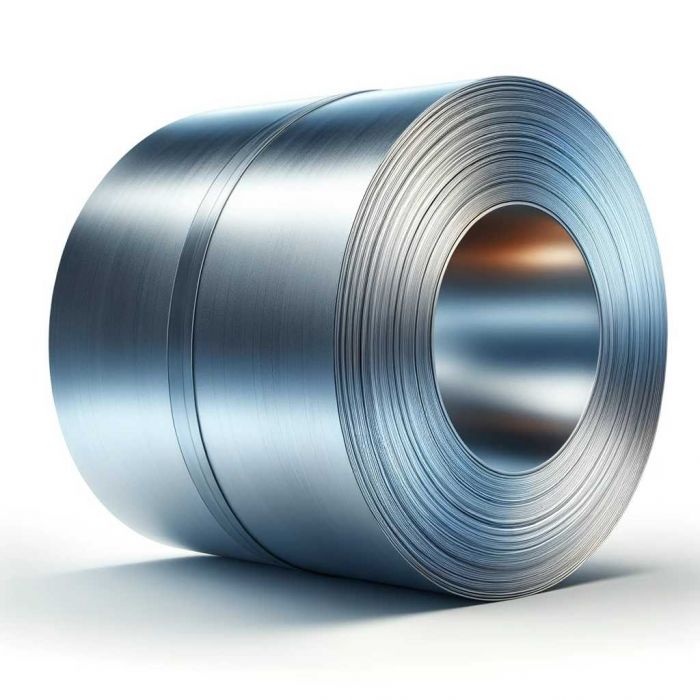

Alright, lemme tell ya ’bout steel sheet roll. Now, this here steel sheet roll, it ain’t too fancy, but it sure is useful for a heap of things. Folks all ’round use it for buildin’ stuff, makin’ machinery, even some big ol’ buildings use this kinda steel. But ya got two main types ya oughta know ’bout: hot-rolled and cold-rolled steel. I’ll tell ya how they’re made an’ why folks might pick one over the other.

Hot-Rolled Steel Sheet Roll

First off, ya got yer hot-rolled steel. This stuff gets made in real hot temperatures, somethin’ like over 1,700 degrees Fahrenheit. Yeah, hotter than ya can imagine. With all that heat, the steel gets soft, easy to work with, so they can shape it into big ol’ sheets or rolls. Thing is, hot-rolled steel ain’t the smoothest. When it cools off, it shrinks a bit and might come out with some rough edges or a few bumps. Ain’t a problem if you’re lookin’ to weld or cut it up for somethin’ heavy-duty.

- Good for big ol’ structures

- Costs less than other types

- Handles bendin’ and weldin’ like a charm

Now, since hot-rolled steel’s all bumpy and rough, it ain’t exactly good for anything where ya need a real smooth finish. But if yer makin’ somethin’ that’s gonna be covered up or needs strength more than looks, well, this one’s just fine.

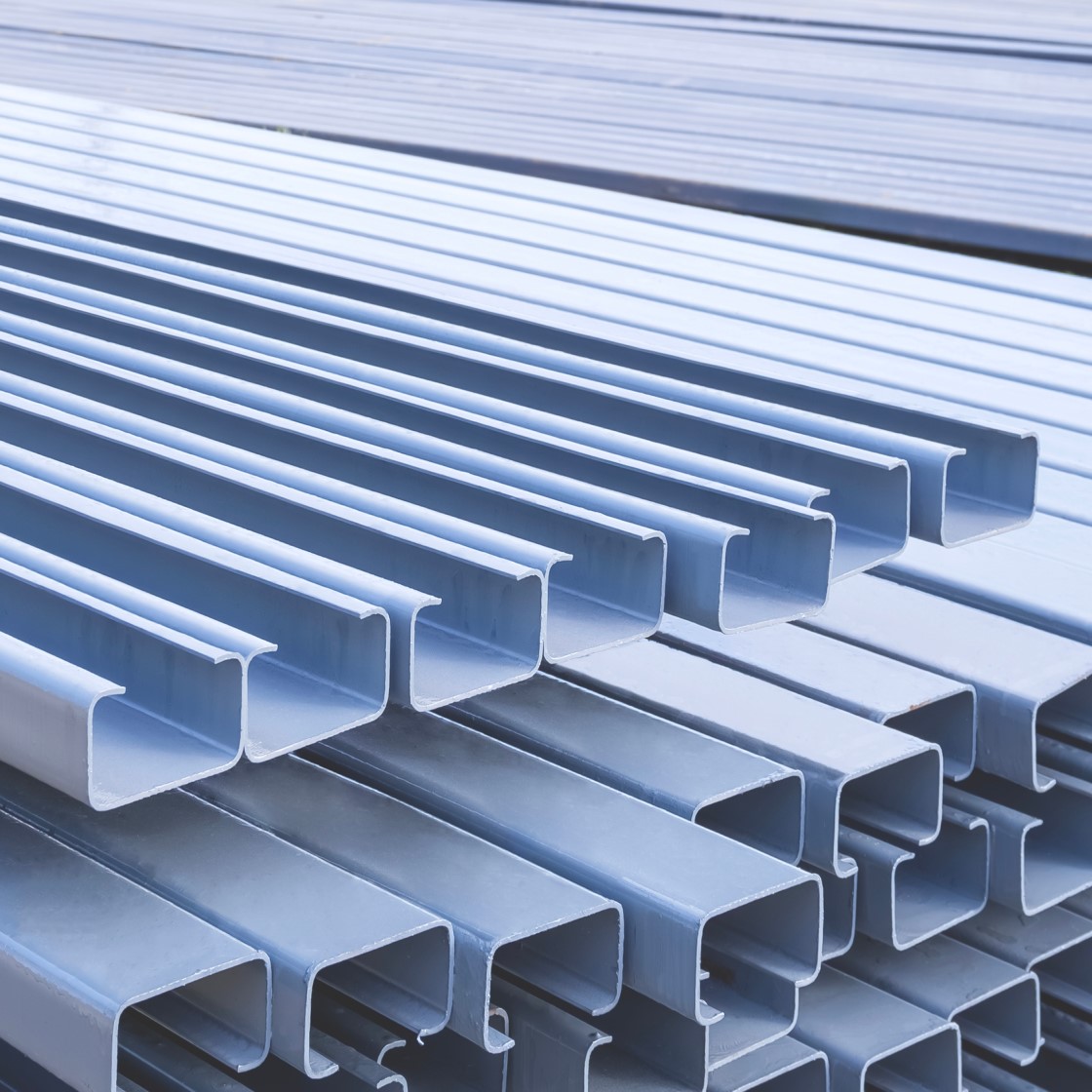

Cold-Rolled Steel Sheet Roll

Now, if hot-rolled steel is like fresh-baked bread, then cold-rolled steel is like takin’ that bread an’ squishin’ it down into a cracker, nice an’ neat. They take the steel after it cools down an’ roll it again. That second rollin’ makes it smoother, stronger, and a whole lot shinier than hot-rolled. It ain’t easy to bend this stuff, but it’s real good when ya need somethin’ that looks all nice an’ smooth. Think of things like home appliances, furniture, or fancy tools.

- Smooth and shiny finish

- Costs a bit more than hot-rolled

- Good for detailed work or stuff on display

Cold-rolled steel might cost ya more, but folks love it for anythin’ that needs that neat, polished look. It’s also harder, so it don’t scratch or dent as easy.

Other Types of Steel Sheet Rolls

Now, besides hot and cold-rolled, there’s also galvanized steel. That’s hot-rolled or cold-rolled steel, just with a coat of zinc on it so it don’t rust up on ya. Real good if ya got stuff outside in the rain or the wind, like fences or outdoor furniture. Then there’s other types too – like perforated steel, which has a bunch of little holes in it, or corrugated steel that’s got them wavy ridges, real strong stuff. Folks use these for all kinds of things dependin’ on what they’re buildin’.

Uses for Steel Sheet Roll

Let me tell ya, there’s a heap of uses for steel sheet rolls, be it hot or cold-rolled. Factories use ‘em for makin’ machines, tools, cars – you name it. Builders use ‘em for walls, roofs, doors, just about anythin’ sturdy. And let’s not forget, farm folks love it too, buildin’ up sheds, barns, and more with it.

Which One to Choose?

So if yer wonderin’ which to go for, here’s the skinny:

- Hot-rolled steel is tough, cheap, and good for big jobs where looks don’t matter.

- Cold-rolled steel is smooth, shiny, and real good for makin’ things that need a nice finish.

- Galvanized steel’s good for outside stuff ‘cause it won’t rust easy.

Final Thoughts

Alright, so steel sheet rolls – they’re just rolled-up sheets of steel, really. Might seem simple, but it’s real handy stuff, ya know? Just pick the kind ya need based on if ya want somethin’ smooth or strong or rust-proof. And there ya go – with a bit of knowin’ what each kind does best, you’ll be pickin’ out steel sheet rolls like a pro in no time!

Tags:[steel sheet roll, hot-rolled steel, cold-rolled steel, galvanized steel, uses of steel sheet rolls]