Oh, when it comes to this cold rolled steel bar, let me tell you, this ain’t no ordinary piece of metal. Folks use it left and right, you know why? ‘Cause it’s tough as nails and has that smooth finish folks like. Now, compared to the hot rolled steel, cold rolled is a bit different. You see, hot rolled steel, they make it while it’s still hot, so it comes out a little rough. But this cold rolled steel bar? They shape it up when it’s cool, and that makes it stronger, harder, and with a finer finish too.

People say cold rolled steel bars got more strength in ‘em ’cause of how they’re made. They don’t just heat it up and shape it any old way. No, they go through a whole process called “cold finishing.” Makes the steel bar all tough and tight. You try bending one of these bars, and you’ll see it’s not easy. It resists breaking and keeps its shape real well. That’s what makes it popular for building and other heavy-duty stuff. You’re not just buying any steel here, you’re buying steel that lasts.

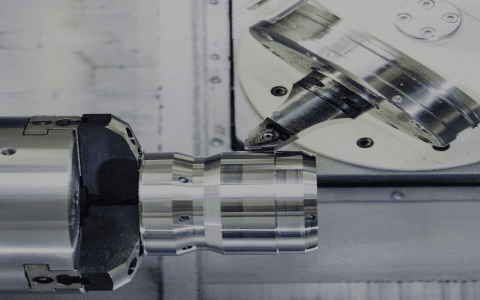

Now, a common type you’ll hear about is the 1018 cold rolled steel bar. You might wonder, what’s so special ’bout this one? Well, it’s got a smooth finish that’s real good if you need precision. Builders and machinists love it ’cause it’s easy to work with, you can get exact sizes, and it won’t mess up on you when you’re working on detailed jobs. See, this kind of steel’s got something they call “dimensional accuracy.” Means it holds its measurements better than hot rolled stuff. You got a job needing exact sizes? This is the one you want.

Another thing folks love about these cold rolled steel bars is the variety. You get all kinds of shapes – round, square, flat, hexagon, you name it. And in all sorts of sizes too, from little rods to big hefty bars. So whatever project you got in mind, whether it’s big or small, there’s a bar to fit. People use these bars in everything from furniture, machine parts, to even big ol’ construction projects.

Why do folks go for cold rolled steel over hot rolled? Well, here’s the thing – hot rolled steel’s cheaper and easier to make, but it just ain’t got the same strength and finish. Cold rolled takes a bit more work, so it’s pricier, but it’s worth every penny if you need durability and a nice smooth look. Hot rolled, you’ll find it in places where looks don’t matter much, but cold rolled? Folks use it where you want it to be strong and look nice too. Imagine a railing or some fancy metal furniture – that’s where this stuff shines.

And let’s talk about low-carbon types, like this 1018 cold rolled steel. That low carbon means it’s easier to shape and work with, and it’s good for welding too. Ain’t too hard to cut, shape, or drill into. But don’t think it’s weak – it’s still got that cold-rolled toughness. Just easier to work with, and that’s what makes it popular in all kinds of jobs.

If you’re fixin’ to buy, check the sizes. You’ll see lengths and widths all ready for any project. Need something small and precise? There’s small bars that’ll fit just right. Need something big and sturdy? You’ll find thicker bars too. This way, you can pick and choose without having to cut it yourself. Saves a heap of time, believe me.

In the end, cold rolled steel bars are reliable, durable, and they sure do look nice with that polished look. So whether you’re building something for show or for strength, you can’t go wrong with cold rolled. Next time you’re at the hardware store, give these bars a look. You’ll see what I mean when I say they’re a whole step up from that hot rolled stuff. That strength, that look – it’s all there in one solid bar.

Tags:[cold rolled steel bar, 1018 cold rolled steel, cold finished steel, steel bar shapes, low carbon steel]